Stainless U bend tubes

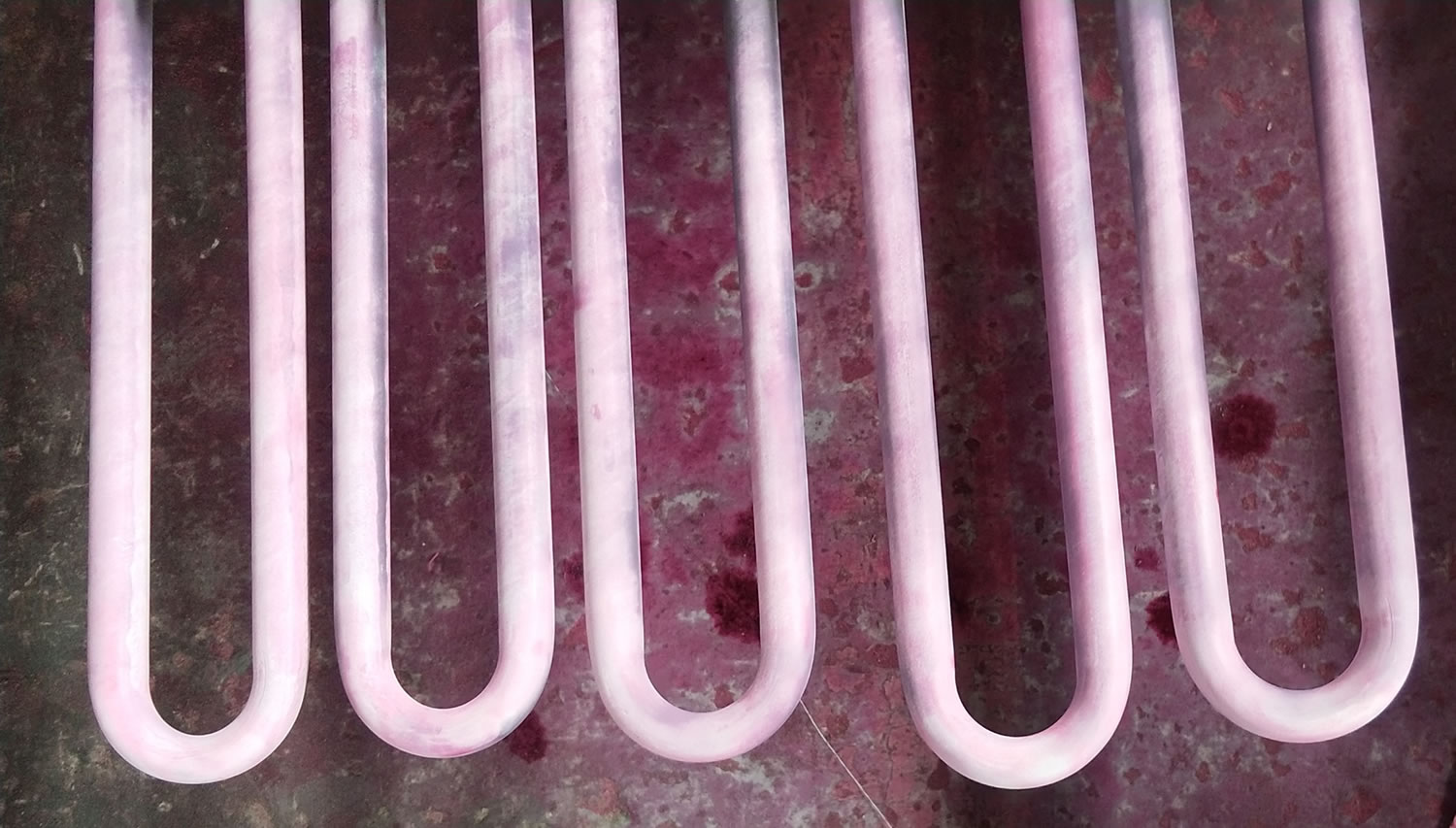

Stainless U bend tubes are made of stainless steel and are bent in a U-shape to redirect the flow of liquids or gases in a piping system.

ASTM A179 U bend tubes for heat exchangers applied mostly in oil and gas plants, chemical and petrochemical plants

Download PDFASTM A179 U bend tubes are a key component in many industrial applications.

These tubes are engineered to precise specifications, ensuring their quality and performance. The U-bend design offers unique advantages in systems where space is limited or complex fluid flow paths are required.

Manufactured in accordance with the ASTM A179 standard, they exhibit excellent mechanical strength and durability. This enables them to withstand the rigors of various operating conditions, including high pressure and temperature variations.

The material composition of these U bend tubes provides resistance to corrosion and wear, prolonging their service life and reducing maintenance costs.

Whether used in heat exchangers, boilers, or other industrial equipment, ASTM A179 U bend tubes offer a reliable and efficient solution for fluid transfer and heat exchange.

ASTM A179 U-Bent tubes are widely used in Heat-exchangers applied mostly in oil and gas plants, chemical and petrochemical plants, refineries, power plants, and renewable energy plants. Low fin tubes can be supplied in the form of U bends.

ASTM A179 U-bend tubes are used in heat exchangers and boilers. They are made from seamless, cold-drawn low-carbon steel tubes. The tubes are used in oil and gas plants, chemical and petrochemical plants, refineries, power plants, and renewable energy plants.

The tubes have a wall thickness of 1.65–2.77 mm. The bending radius is from 1.5 times the outer diameter to 1250 mm.

ASTM A179 tubes are available in different specifications, including:

We bend ASTM A179 b bend tubes with round, rectangular, square, plus oval cross sections used in medical, automotive, plus electronics industries.

Depending on the bend radius and tube thickness, heat treatment might be required to avoid cracking. ASTM A179 tubes typically have good ductility, but for tighter bends, localized heating may be beneficial.

Seamless cold-drawn low carbon steel tubes for use in heat exchangers and condensers" refers to tubes specifically designed for the manufacturing of heat exchangers and condensers. These tubes typically possess high strength, good toughness, and excellent thermal conductivity, making them suitable for transferring heat in such applications.

To bend ASTM A179 tubes, you will need specialized equipment and careful control of the bending process to ensure the tubes maintain their structural integrity. Here are the general steps involved in bending ASTM A179 tubes:

Prepare the equipment: Set up a tube bending machine specifically designed for bending tubes. Ensure that the machine is properly calibrated and in good working condition.

Select the appropriate bending tool: Choose a bending tool that matches the desired bend radius and angle for the ASTM A179 tubes. The tool should be compatible with the tube diameter and wall thickness.

Mark the bending points: Use a marker or scribe to mark the precise points on the tube where the bends will be made. This will help ensure accuracy during the bending process.

Secure the tube: Secure the ASTM A179 tube in the bending machine, making sure it is properly aligned with the bending tool.

Bend the tube: Activate the bending machine to gradually bend the tube to the desired angle and radius. The machine will apply force to the tube at the marked bending points, gradually shaping it into the desired U-shaped configuration.

Inspect the bend: After the bending process is complete, visually inspect the tube to ensure that the bend is smooth and free from any cracks or deformations.

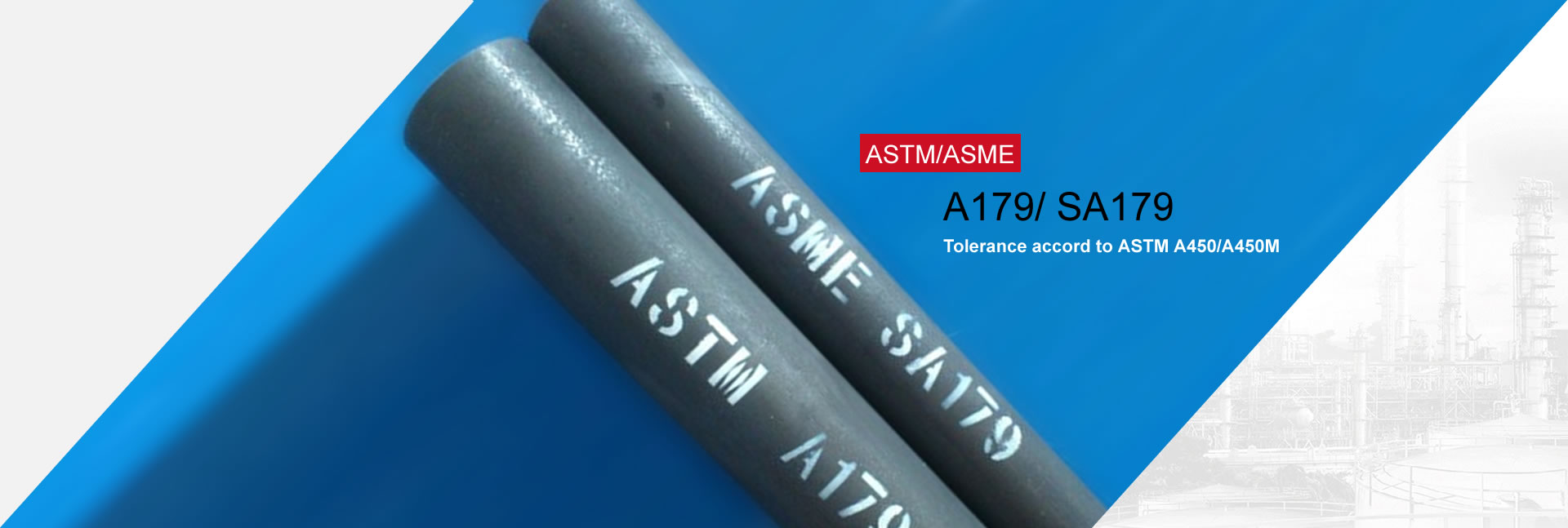

ASTM A179 is a standard specification for seamless cold-drawn low-carbon steel tubes used in tubular heat exchangers, condensers, and similar applications.

The ASTM A179 tubes are produced through a cold-drawing process, which helps to improve their dimensional accuracy and surface finish.

ASTM A179 U bend tubes are widely used in industries such as petroleum, chemical, medical, food, light industry, machinery, instrument, include industrial pipeline and mechanical structure parts, etc.

ASTM A179 covers minimum-wall thickness, seamless cold-drawn low-carbon steel tubes for tubular, heat exchanger, condensers, and other heat transfer services. seamless ASTM A 179 steel tube is supplied and produced by cold drawning method. Chemical composition contains carbon, manganese, phosphorus, and sulfur.

ASTMA179/ASME SA179 standard is applicable for steel pipes together with outside diameter of 1/8in-3in. (32 mm to 76.2 mm). Our rolling technology has reached the international advanced spot. JST is able to manufacture cold drawn seamless steel tubes with uniform wall depth. Their tolerance is relatively smaller standard your own.

When seamless carbon steel pipes are during the last cold drawing procedure, they will enter micro oxidization and non-oxidation heat treatment furnace for thermal treatment (Temperature is 1200℉ (650℃) if not more.). This makes the surface of cold drawn seamless steel tubes match the no oxide scale standards, and guarantees smooth surface and stable performance.

JST adopts professional hardness testing equipment to find out the hardness of seamless carbon steel pipes. The Rockwell hardness value not able to exceed 72 HRB.

Top rated program customers' requirements, we can analyze the cold drawn seamless steel tube advertise its chemical composition meet standards. We choose one from 250 pipes or select one in a furnace to investigate. If the product analysis fails, then choose another two seamless carbon steel pipes. All elements of two steel pipes tend to be in accordance with standards, and then these pipes can be delivered.

Note:

| OD(mm) | Wall Thickness Unit(mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5 - 7 | 7.5 - 8 | 8.5 - 9 | 9.5 - 10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ133 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ140 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ146 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ152 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ159 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ168 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| C | Si | Mn | P | S | Mo | Cr | V |

|---|---|---|---|---|---|---|---|

| 0.06-0.18 | / | 0.27-0.63 | ≤0.035 | ≤0.035 | / | / | / |

| Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

Hardness (HRB) |

|---|---|---|---|

| ≥325 | ≥180 | ≥35 | ≤72 |

ASTM A450 covers carbon and low alloy steel tube. Steel samples shall be melt processed and shall either be ingot cast or strand cast. Heat and product analyses shall be performed on the steel materials. Steel specimens shall also undergo tensile tests and shall conform to required values of yield strength and elongation. Flattening test, reverse flattening test, flaring test, flange test, hardness test, hydrostatic test, air underwater pressure test, and nondestructive tests shall be performed on the steel materials.

| OD In (mm) | + | - | WT In(mm) | + | - |

|---|---|---|---|---|---|

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 11.1/2(25.438.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2<2(38.150.8) | 0.20 | 0.20 | |||

| 2<2.1/2(50.863.5) | 0.25 | 0.25 | |||

| 2.1/2<3(63.576.2) | 0.30 | 0.30 | |||

| 34(76.2101.6) | 0.38 | 0.38 | |||

| >47.1/2(101.6190.5) | 0.38 | 0.64 | |||

| >7.1/29(190.5228.6) | 0.38 | 1.14 |

We packs all U Tube bundles in bespoke wooden boxes and separate all U Tubes of different radii using finger pallets to facilitate easy assembly of bundles on receipt.

Any type of packing is available according to customer need to worldwide destinations.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.