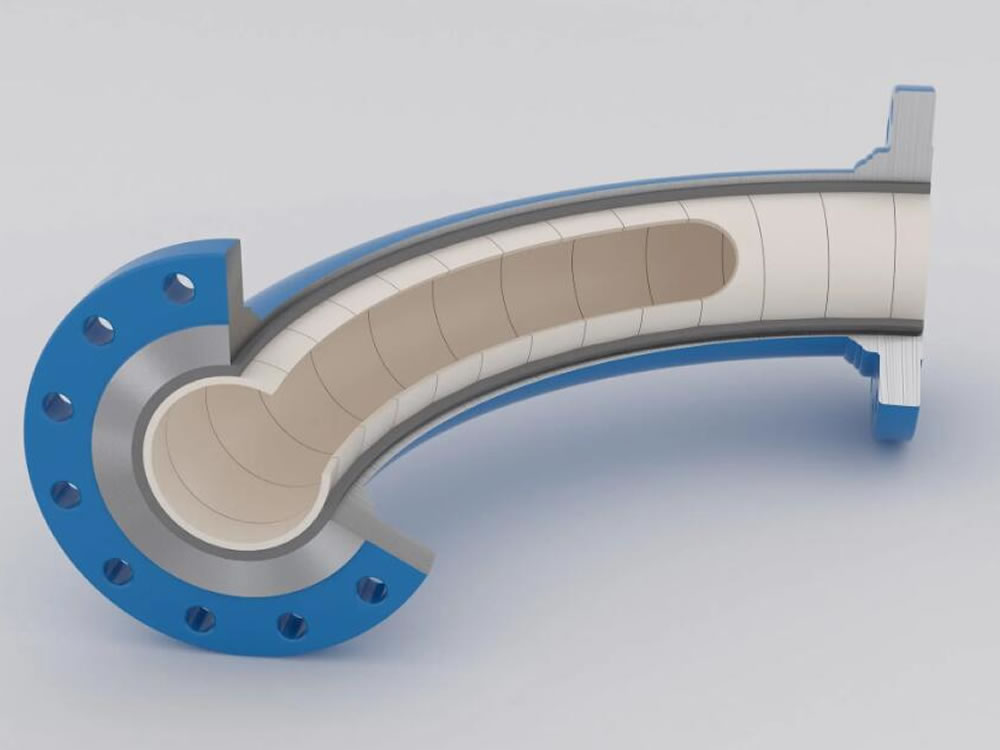

Ceramic sleeve lined pipe has a continuous ceramic liner covering the inner surface of the pipe.

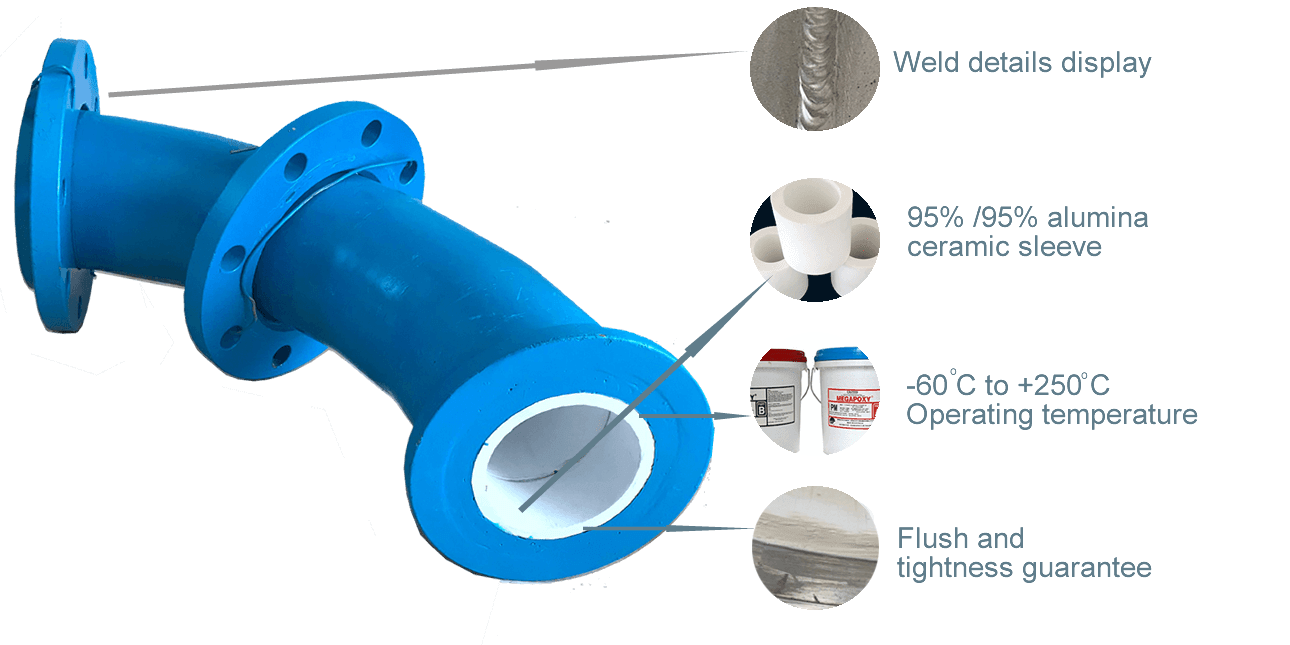

95% alumina ceramic sleeve lined pipes, elbows and T pipes have been largely applied in lithium battery material conveying system in recently years.

Download PDF

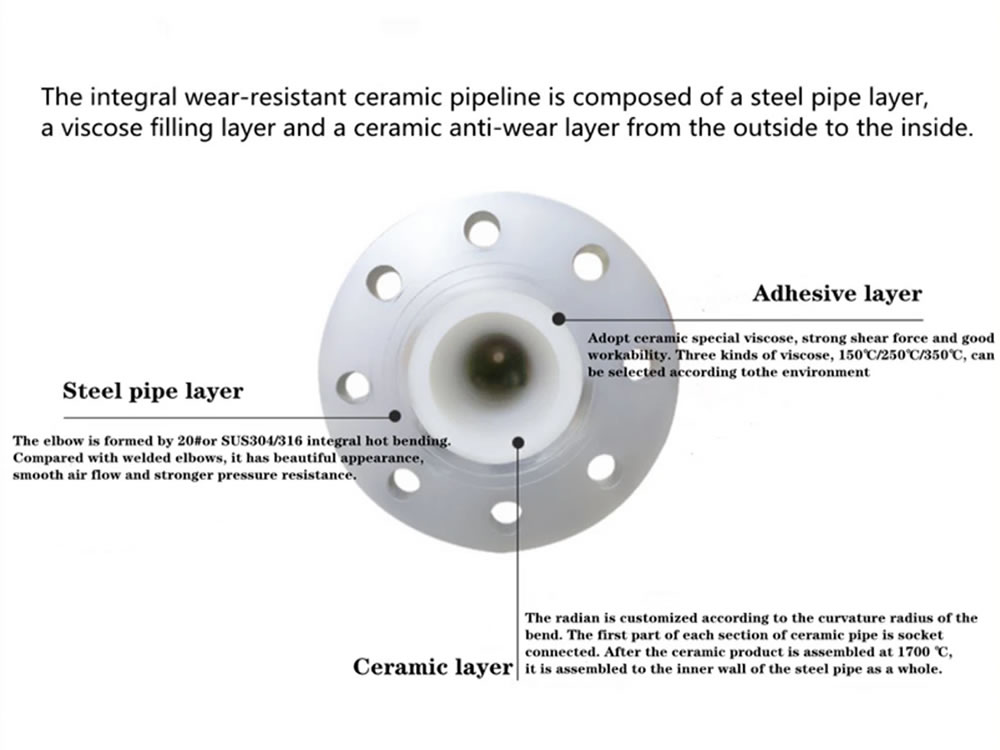

Ceramic sleeve lined pipe refers to a type of pipe where the inner surface is covered with a continuous ceramic liner or sleeve. This ceramic liner is typically made of high-quality alumina ceramics, which provide excellent resistance to wear, abrasion, and corrosion.

The ceramic sleeve lined pipe is commonly used in industrial applications where the pipeline is exposed to harsh conditions, such as in mining, power generation, oil and gas, and lithium battery material conveying systems The ceramic liner helps to protect the inner surface of the pipe from the abrasive or corrosive materials being transported, thereby extending the service life of the pipeline.

The ceramic sleeve lined pipe is often used in areas where traditional ceramic tiles may not be suitable or practical. The continuous ceramic liner provides a smooth and even interior surface, which helps to minimize friction and improve the flow efficiency of the pipeline.

The installation process of ceramic sleeve lined pipe involves assembling the ceramic sleeve into the steel pipe using a high-strength-temperature-resistant epoxy adhesive. This ensures a secure and durable bond between the ceramic liner and the pipe.

It is important to note that the specific design, dimensions, and properties of ceramic sleeve lined pipes may vary depending on the manufacturer and the project requirements. Consulting the manufacturer's specifications or working with qualified engineers is recommended to ensure the proper selection and installation of ceramic sleeve lined pipes in a specific project.

The lithium battery industry is absolutely booming as technology marches forward and industries wholeheartedly shift towards renewable energy sources!

The efficiency and longevity of lithium batteries are highly contingent on the materials employed in their construction. And that's precisely where those amazing wear-resistant ceramic tubes step in!

The main raw material of wear resistant ceramic ring is a special kind of ceramic with AL2O3 as the and the rare metal oxide as the flux, which is melted by high temperature at 1700 °C. The Ceramic Sleeves Lined Pipe as a whole part, and then assemble it into the steel pipe with our high-strength-temperature-resistant epoxy adhesive.

Recently 95% alumina ceramic sleeve lined pipes, elbows and T pipes have been largely applied in lithium battery material conveying system. The big diameter ceramic sleeve is always a big problem for the ceramic tube manufacturers since it’s very difficult to control the deformation rate of the ceramic sleeve after it’s sintering .Also It will also need an advanced and big isostatic pressing machine to do this .So it will not only express the company’s production capability ,but company’s technology. Right now, our factory have owned both advantages which are wear resistant ceramic pressing facilities and technologies.

| Items | 92% | 95% |

|---|---|---|

| Al2O3 | ≥92% | ≥95% |

| SiO2 | 0.0451 | 0.028 |

| Fe2O3 | 0.0001 | 0.0001 |

| TiO2 | 0.0005 | / |

| CaO | 0.018 | 0.0045 |

| MgO | 0.011 | 0.0051 |

| K2O | 0.0004 | 0.0003 |

| Na2O | 0.0031 | 0.0063 |

| Volume Density | 3.62 g/cm3 | 3.65 g/cm3 |

| Water Absorption (%) | ≤0.02% | ≤0.02% |

| POROSITY | ≤1 | ≤1 |

| Hardness | 9 Mohs | 9 Mohs |

| Flexural strength | ≥2000 Mpa | ≥2250 Mpa |

| Abrasion | ≤0.02 | ≤0.02 |

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features as an abrasion resistant, heat resistant and corrosion resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

| Data | Metric | Imperial |

|---|---|---|

| Tensile Strength, Ultimate | 655 MPa | 95 ksi |

| Tensile Strength, Yield | 290 MPa | 42 ksi |

| Elongation at Break (in 2") | 0.55 | 0.55 |

| Rockwell Hardness | B84 | B84 |

304 Stainless Steel Plate has very good formability and can be readily welded by all common methods.

Ceramic sleeve lined pipes are commonly used in industries such as mining, power generation, cement, steel, and chemical processing. They are particularly effective in applications where materials with high abrasiveness or corrosiveness need to be transported.

| Industry | Material |

|---|---|

| 1. Abrasive products | Grinding wheel granules |

| 2. Aluminium plants | Calcined alumina, bauxite, electrode, carbon, crushed bath |

| 3. Iron & Steel | Sinter dust, limestone, lime injection, coal, iron carbide, alloy additives |

| 4. Mineral wool & insulation products | Perlite, stone dust, refractory fibers, production wastes, dust from sawing operations |

| 5. Foundries | Molding sand, dust collection |

| 6. Glass plants | Batch, cullet, quartz, kaoline, feldspar |

| 7. Breweries, grain processing, feed mills | Corn, barley, soy beans, malt, cocoa beans, sunflower seeds, rice hulls, malting plants |

| 8. Cement | Clinker dust, limestone, cement, fly ash, coal, blast furnace slag |

| 9. Chemical plants | Caustic lime, fertilizers, lime dust, chrome ore, paint pigments, plastic pallets with glass fi bers |

| 10. Mineral mining plants | Kiln feed, ore concentrate, coal tailings, dust |

| 11. Coal fired power stations | Coal, fly ash, pyrites, slag, ash, limestone |

| 12. Coal mines | Coal dust, mine waste for backfi lling |

| 13. Technical carbon products | Technical carbon, dust, graphite for electrodes |

Abrasion resistant pipe using steel skeleton packaging, and the two ends of the pipe with plastic head, to prevent dust and rain into the pipeline inside, to ensure the beauty of the product.

For different production environments, our company has developed a wear-resistant pipe for a variety of media, based on the temperature, wear and corrosion requirements of the field media, and for the initial application of the scene, our company to provide wear-resistant ceramic ring for the Lined composite straight pipe design to meet the on-site wear resistance, heat resistance and corrosion resistance requirements, in view of this program for the new design (formerly ceramic chip technology, there are many gaps, easy to wear).

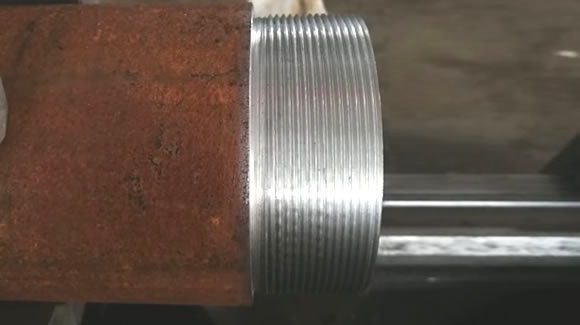

After the ceramic ring in the pipe is installed and the thread is processed, the dirt outside the pipe is cleaned, and the outer surface of the pipe is treated with three layers of anticorrosive paint to meet the export requirements.

| Item | Data | Characteristics of binder |

|---|---|---|

| Density (g/cm3) | 1.32 | We use the Australian Megapoxy high strength structural adhesive, this structural glue is modified epoxy resin polymer, anti-aging ability, and wear-resistant ceramic bonding to form a strong and cushion of the anti-wear layer, cured water, anti-corrosion performance is excellent, toughness, displacement-resistant effect is remarkable.

|

| Compressive strength (MPa) | 40 | |

| Shear Strength MPa | 26 | |

| Impact toughness Kj/m2 | 10 | |

| Hardness HB | 9.5 | |

| Elastic Modulus GPa | 2.2 | |

| Expansion coefficient 10-6/℃ | 20.1 | |

| Softening temperature℃ | 263 | |

| Coking temperature℃ | 335 | |

| Acid resistance(24H) | Stability | Test solution : 15%H2SO4 |

| Alkali resistance(24H) | Stability | Test solution: NaOH |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.