Silicon Carbide

Silicon carbide, mainly consisting of SiC, also known as carborundum, is a hard chemical compound containing silicon and carbon.

Double-tube conveying is a method of transporting materials or fluids that utilizes a system comprising two tubes or pipes.

Download PDFTurbulent Flow Double-walled Pipe is a special pipeline structure used for heat transfer and fluid mixing.

The inner-tube to pour compressed air separately in the pipage is installed. This structure in which a pipe was installed is the feature and a large number of advantages are offered to double-tube conveying systems by this structure.

The presence of the inner tube is a defining characteristic of double-tube conveying systems. This inner tube serves to transport compressed air within the pipeline, and it offers several notable benefits to this method of material transport or fluid flow.

Turbulent flow is the irregular and chaotic movement of fluid with rapid changes in velocity and direction. It is typically observed at higher flow rates or in pipes with rough surfaces, resulting in increased mixing and improved heat transfer performance. Turbulent flow is widely used in various engineering applications, such as heat exchangers and certain chemical processes, where efficient heat transfer or fluid mixing is required.

A turbulent flow double-walled pipe combines the advantages of the double-walled design for protection and insulation, along with the enhanced fluid dynamics of turbulent flow, making it suitable for applications that demand effective heat transfer and fluid mixing capabilities.

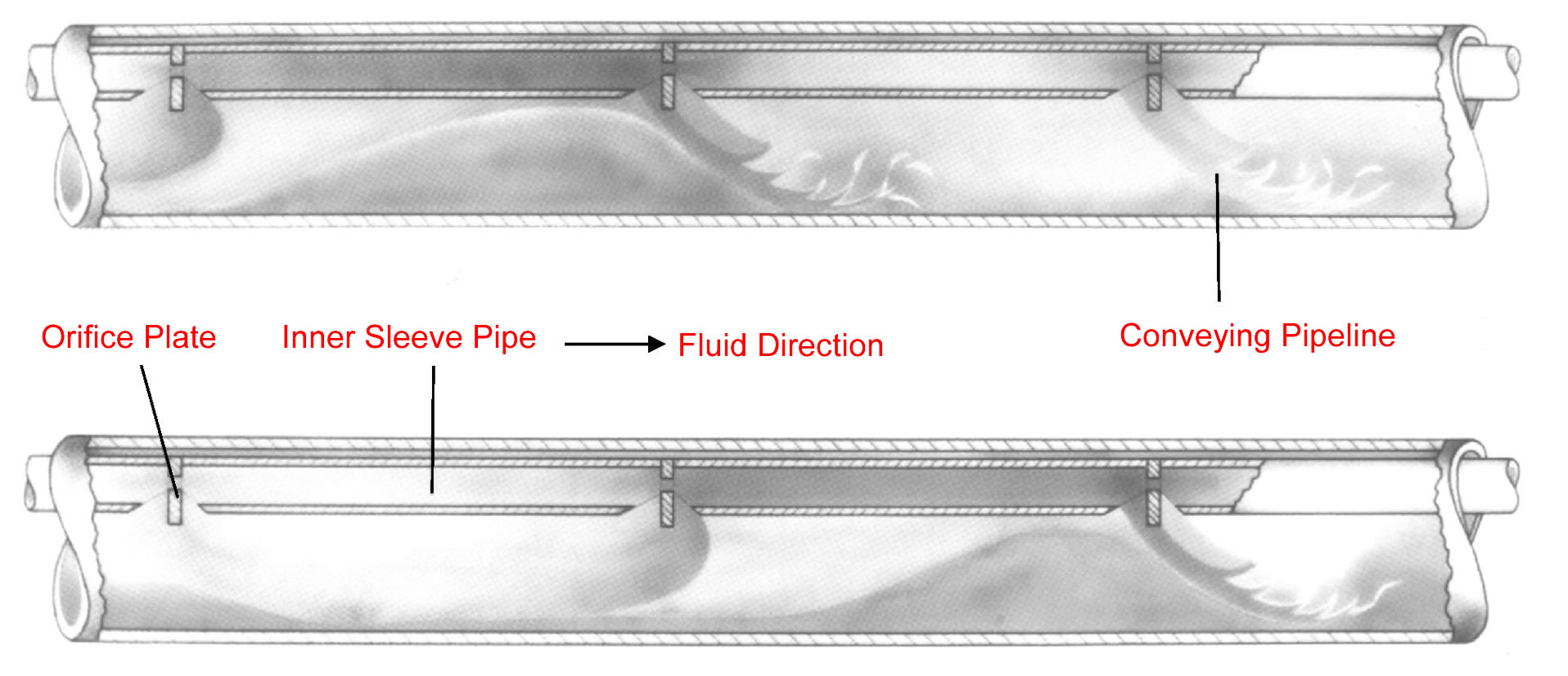

By applying turbulent flow double-walled pipes to the horizontal pneumatic conveying pipes, it effectively prevents pipe blockage, and the anti-blocking mechanism lies in the special structure of the double-walled pipe. When the ash-gas mixture flows inside the pipe, it often causes gradual deposition of dry ash within the pipe, leading to blockage. When blockage starts to occur, compressed air flows through the small pipe, and through the openings and throttle orifices on the small pipe, the blocked section is disturbed, gradually dislodging the deposited dry ash, thereby avoiding complete blockage of the conveying pipe.

Working Principle: An auxiliary air pipe is added above the conveying pipe, with nozzles installed at regular intervals along the auxiliary air pipe. The air and material mixture enters the double-walled pipe at a low velocity under the conveying pressure and moves slowly forward inside the pipe. When material deposition and blockage occur due to low flow velocity, air flows through the auxiliary air pipe and exits at high velocity through the nozzles, disturbing and clearing the deposited material, allowing it to continue moving forward. This continuous disturbance ensures dense-phase, low-speed material transportation without blockages, ensuring safe and reliable system operation. As the system may experience instantaneous blockages, it incorporates some plug flow conveying, which determines the characteristics of low-speed, high solid-to-gas ratio transportation. Due to its ability to automatically detect blockage locations, adjust the air velocity inside the small pipe according to blockage conditions, and perform automatic clearing, it possesses the unique technical advantage of never blocking.

Ceramic Lined Double-walled Pipe is a type of double-walled pipe where the inner layer is lined with ceramic material for wear and corrosion resistance.

This design is commonly used in industries where the conveyed material is abrasive, corrosive, or subject to high wear, and the ceramic lining provides excellent protection to the inner pipe, extending its service life. Ceramic lined double-walled pipes are commonly used in applications such as mining, cement, power generation, and chemical processing, where the transportation of abrasive materials can cause rapid wear and tear on standard pipes.

Fly ash handling systems are designed to collect, convey, store, and transport fly ash residue generated from coal combustion in power plants.

Pneumatic Conveying Double-walled Pipe is a type of double-walled pipe designed for use in pneumatic conveying systems.

Pneumatic conveying is a method of transporting bulk materials through a pipeline using air or gas as the conveying medium. It is commonly used in industries such as food processing, chemical, pharmaceutical, and manufacturing, where materials like powders, granules, or pellets need to be transported efficiently and with minimal contamination.

The double-walled pipe design provides additional benefits such as improved insulation, reduced heat transfer, and protection against wear, especially when conveying abrasive or corrosive materials. It helps ensure the efficient and reliable transportation of materials while minimizing the risk of blockages or damage to the conveying system.

The pneumatic conveying double-walled pipe is designed to facilitate the transportation of bulk materials using air or gas as the conveying medium. It consists of two separate pipes, one inside the other, with an air or insulating gap between them.

During operation, the bulk materials, such as powders, granules, or pellets, are introduced into the inner pipe. Compressed air or gas is then introduced into the annular space between the two pipes. The high-velocity air or gas flow entrains the bulk materials, causing them to be suspended and carried along inside the inner pipe.

Pneumatic conveying is a technology used to transport solid materials through a closed pipeline using air or gas with a certain velocity and pressure. Dense-phase pneumatic conveying with a double-walled pipe is a positive pressure dense-phase pneumatic conveying technology that emerged in the mid-1980s. Its main characteristic is the installation of a smaller diameter inner pipe in the upper part of the conveying pipeline, with specially designed openings spaced at regular intervals.

When material blockage occurs at a certain point in the conveying pipeline, the pressure ahead of the blockage increases. High-pressure air flows into the inner pipe, and compressed air from the inner pipe exits through the openings downstream of the blockage at a higher velocity. This creates disturbance and clearance to the blocked material, ensuring the normal transportation of materials inside the pipe. The double-walled pipe design offers advantages such as improved insulation, wear protection, and reduced blockages, making it an efficient and reliable solution for the pneumatic conveying of solid materials in various industries.

Dual-walled Turbulent Pneumatic Conveying System used for the efficient transportation of solid materials through a pipeline using air or gas as the conveying medium. This system combines two key features:

Dual-walled Design: The system includes a pipeline with an inner pipe enclosed within an outer pipe, creating an air or insulating gap between the two pipes. This dual-walled structure provides several benefits, including improved insulation, reduced heat transfer, and protection against wear, especially when conveying abrasive or corrosive materials.

Turbulent Pneumatic Conveying: The system utilizes the characteristics of turbulent flow during the material transportation process. Turbulent flow is an irregular and chaotic movement of fluid, which allows for enhanced mixing and efficient transportation of solid materials within the pipeline.

The dual-walled turbulent pneumatic conveying system is commonly used in various industries, such as mining, cement, chemical processing, and food processing, where the transportation of bulk materials with minimal contamination and reduced wear is essential. It offers reliable and continuous material transportation, minimizing the risk of blockages and ensuring the smooth operation of the conveying process.

Improved insulation: The air or insulating gap between the two pipes helps reduce heat transfer and maintain the temperature of the conveyed materials, which is especially important for temperature-sensitive substances.

Wear protection: In applications where the conveyed materials are abrasive or corrosive, the inner pipe can be lined with wear-resistant materials like ceramics or other specialized coatings, extending the pipe's service life.

Reduced blockages: The smooth and controlled flow of materials inside the inner pipe, along with the protection offered by the double-walled design, helps minimize the risk of blockages, ensuring the efficient and reliable transportation of materials.

Overall, the pneumatic conveying double-walled pipe provides an effective and reliable solution for the bulk transportation of materials in various industries, maintaining product integrity and minimizing downtime.

Our range offers durable solutions for various applications.

Browse now for reliable products!

The structure of a double-jacket pipe consists of a large outer pipe which houses a smaller inner pipe. Specifically, the inner pipe has regularly spaced openings. The principle behind double-jacketed pipes is to use them in pneumatic conveying systems, particularly in horizontal pipelines, to effectively prevent blockages. This prevention mechanism is due to the unique structure of the double sleeve pipe. As the ash-air mixture flows through the pipe, dry ash deposits gradually accumulate inside the pipe for various reasons, leading to blockages. When dry ash begins to accumulate and threatens to block, compressed air is passed through the small pipe. By passing through the openings and orifices on the small pipe, the compressed air disturbs the obstructed areas, gradually dislodging the accumulated dry ash. This action helps to prevent clogging of the conveying pipe.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.