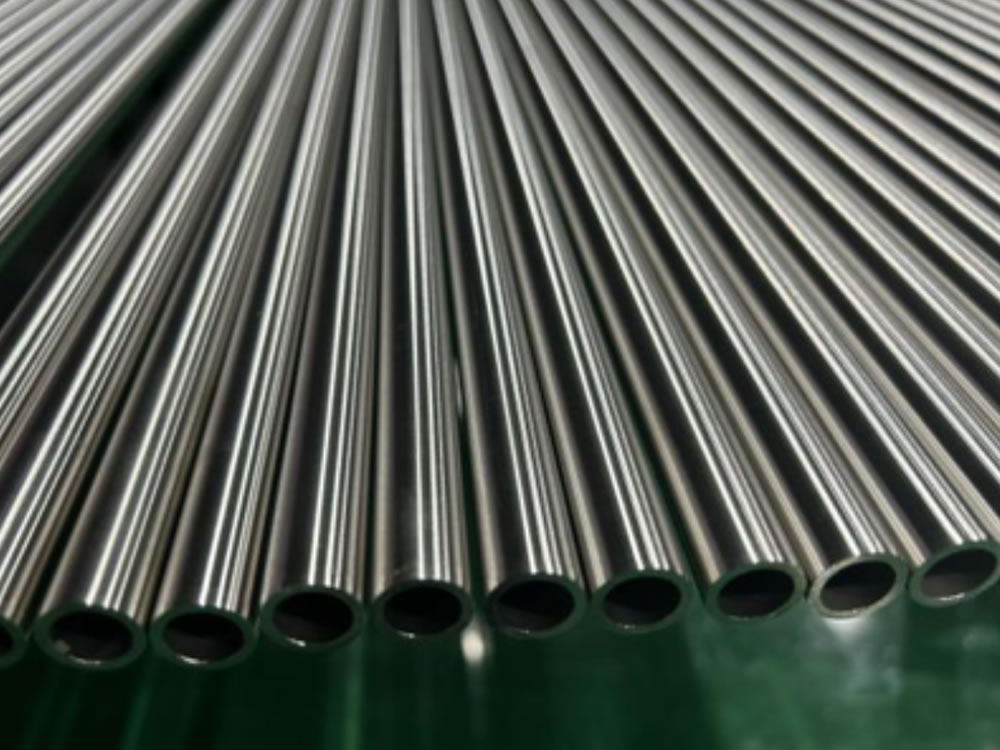

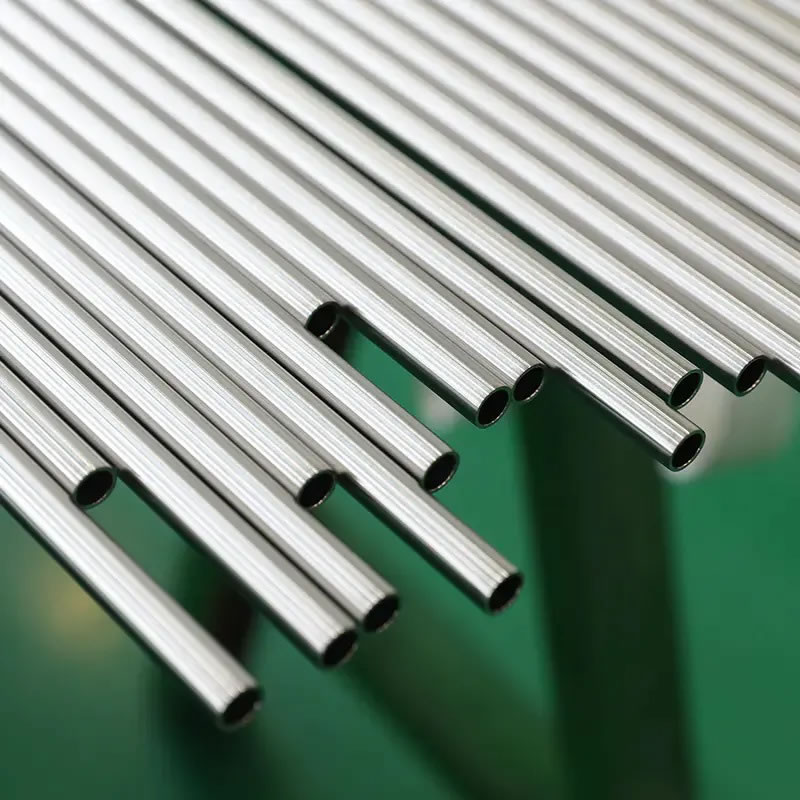

ASTM A269 specification outlines the requirements for seamless and welded austenitic stainless steel tubing intended for general corrosion-resistant and low or high-temperature service.

Download PDFIt covers tubes of various sizes, shapes, and thicknesses, designed to meet the stringent demands of industries requiring high-quality stainless steel tubing.

The prominence of ASTM A269 stems from its key features and characteristics that cater to industries' specific needs:

ASTM A269 encompasses a range of stainless steel grades, including austenitic, ferritic, and duplex stainless steels. This diversity allows industries to select the most suitable material for their application, balancing factors like corrosion resistance, strength, and cost.

The specification accommodates both seamless and welded tubing. Seamless tubes offer superior integrity and corrosion resistance, while welded tubes are more cost-effective and can be manufactured in various shapes and sizes.

ASTM A269 stipulates strict dimensional tolerances to ensure the tubes' precise dimensions and consistent performance. This precision is critical in applications that demand accurate fits and connections.

To ensure the highest quality standards, ASTM A269 stainless steel tubes undergo rigorous testing, including visual inspection, dimensional checks, and non-destructive testing methods such as eddy current testing and hydrostatic testing. These tests guarantee the tubes' integrity, dimensional accuracy, and corrosion resistance.

Selecting the appropriate stainless steel grade is paramount when adhering to ASTM A269. Factors such as the corrosive nature of the conveyed fluid, temperature, and mechanical stress must be considered to ensure optimal performance and longevity.

ASTM A269 plays a pivotal role in the realm of stainless steel tubing, providing industries with a reliable standard for seamless and welded austenitic stainless steel tubes. From chemical and pharmaceutical sectors to food and beverage industries, these tubes serve as the backbone of critical processes, ensuring corrosion resistance, durability, and performance.

As industries continue to evolve and demand higher standards, ASTM A269 remains a steadfast companion, supporting innovation and progress across various sectors.

The ASTM A269 specification covers nominal-wall-thickness, seamless and welded austenitic steel tubing for general corrosion-resisting and low- or high-temperature service.

ASTM A269 tubing is for general service, usually, it is applied in equipment and instruments, also under low or high temperature environment, therefore, ASTM A269 tubing is also used for heat transfer equipment.

ASTM A269 welded tube dimensional tolerance are in accordance with ASTM A1016 specification, wall thickness tolerance is +/-10% of thickness, comparing with ASTM A269 tube size tolerance as follow.

ASTM A269 Seamless Stainless Steel Tubing is used for low temperature and high temperature services. These pipes could be made from austenitic steel types under electric resistant weld, electric fusion weld or seamless cold drawing mechanisms. The SA269 Tubing can also have different finishes and can be heat treated. The SA 269 Tp 316 is more corrosion resistant than the 304 material types and it is used in applications with high pressures and high temperatures as well as low pressure and low temperatures. Therefore the SA 269 Tp 304 and the ASTM A269 Tp316l material grade pipes have different schedules. These schedules correspond to different wall thickness corresponding to different nominal diameters.

The ASTM A269 Tp316 Tube is used in high temperature services with high pressures such as the hydraulic systems. Other specifications of the ASTM A269 Tube could be used in textile, chemical and marine industries. The ASTM A269 Tolerances are high for chloride ion rich environments and most oxidizing agents. Therefore the ASTM A269 Seamless Stainless Steel Tubing is a good choice for chemical and marine industries. Also the corrosion resistance for general services is great with ASTM A269 Seamless Tubing. Due to the accuracy in dimensions, strength and corrosion resistance, the ASTM A269 SS Tubing is widely used along these industries. Oshwin Overseas is a supplier of these products and our ASTM A269 Tubing Pressure Rating allow us to produce different pressure classes of these pipes for customer requirements. You can get a full catalog of our products upon inquiry.

| Standard | OD | WTH | L | |

| ASTM A269 | <38.1mm | ±0.13mm | OD<12.7mm ±15% OD≥12.7mm ±10% |

OD<38.1mm +3.20mm -0mm OD≥38.1mm +4.80 -0mm |

| ≥38.1mm~88.9mm | ±0.25mm | |||

| ≥88.9mm~139.7mm | ±0.38mm | |||

| ≥139.7mm~203.7mm | ±0.76mm | |||

| ≥203.7mm~304.8mm | ±1.01mm | |||

| ≥304.8mm~355.6mm | ±1.26mm | |||

ASTM A269 tubes should be welded type or seamless type, which is made in cold finished or hot finished.

More specifically, the ASTM A269 specification is intended for uses such as:

| Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

| 316 | 0.08 | 2.00 | 0.045 | 0.030 | 1.0 | 11-14 | 16-18 | 2-3 |

| 316L | 0.035 | 2.00 | 0.045 | 0.030 | 1.0 | 10-14 | 16-18 | 2-3 |

| Grade | Tensile Strength(Mpa) | Yield Point(Mpa) | Elongation(%) | Elongation(%) |

| 316L | 485 | 170 | 35 | 25 |

| 316 | 515 | 205 | 35 | 25 |

ASTM A269 TP316L Stainless Steel Tubing Application

From TP316L chemical composition and mechanical property data sheet, TP316L is obvious a ideal material in high temperature and corrosion environment, excellent corrosion resistance performance in wide applications.

| OD inches | Ave. Wall inches | D/t Ratio | ID inches | Tube Cross Sectional Area (in2) | Internal Area (in2) |

| 0.250 | 0.020 | 12.50 | 0.210 | 0.0145 | 0.0346 |

| 0.250 | 0.028 | 8.93 | 0.194 | 0.0195 | 0.0296 |

| 0.250 | 0.035 | 7.14 | 0.180 | 0.0236 | 0.0254 |

| 0.250 | 0.049 | 5.10 | 0.152 | 0.0309 | 0.0181 |

| 0.250 | 0.065 | 3.85 | 0.120 | 0.0378 | 0.0113 |

| 0.375 | 0.020 | 18.75 | 0.335 | 0.0223 | 0.0881 |

| 0.375 | 0.028 | 13.39 | 0.319 | 0.0305 | 0.0799 |

| 0.375 | 0.035 | 10.71 | 0.305 | 0.0374 | 0.0731 |

| 0.375 | 0.049 | 7.65 | 0.277 | 0.0502 | 0.0603 |

| 0.375 | 0.065 | 5.77 | 0.245 | 0.0633 | 0.0471 |

| 0.500 | 0.020 | 25.00 | 0.460 | 0.0302 | 0.1662 |

| 0.500 | 0.028 | 17.86 | 0.444 | 0.0415 | 0.1548 |

| 0.500 | 0.035 | 14.29 | 0.430 | 0.0511 | 0.1452 |

| 0.500 | 0.049 | 10.20 | 0.402 | 0.0694 | 0.1269 |

| 0.500 | 0.065 | 7.69 | 0.370 | 0.0888 | 0.1075 |

| 0.500 | 0.083 | 6.02 | 0.334 | 0.1087 | 0.0876 |

| 0.625 | 0.020 | 31.25 | 0.585 | 0.0380 | 0.2688 |

| 0.625 | 0.028 | 22.32 | 0.569 | 0.0525 | 0.2543 |

| 0.625 | 0.035 | 17.86 | 0.555 | 0.0649 | 0.2419 |

| 0.625 | 0.049 | 12.76 | 0.527 | 0.0887 | 0.2181 |

| 0.625 | 0.065 | 9.62 | 0.495 | 0.1144 | 0.1924 |

| 0.625 | 0.083 | 7.53 | 0.459 | 0.1413 | 0.1655 |

| 0.625 | 0.095 | 6.58 | 0.435 | 0.1582 | 0.1486 |

| 0.625 | 0.109 | 5.73 | 0.407 | 0.1767 | 0.1301 |

| 0.750 | 0.028 | 26.79 | 0.694 | 0.0635 | 0.3783 |

| 0.750 | 0.035 | 21.43 | 0.680 | 0.0786 | 0.3632 |

| 0.750 | 0.049 | 15.31 | 0.652 | 0.1079 | 0.3339 |

| 0.750 | 0.065 | 11.54 | 0.620 | 0.1399 | 0.3019 |

| 0.750 | 0.083 | 9.04 | 0.584 | 0.1739 | 0.2679 |

| 0.750 | 0.095 | 7.89 | 0.560 | 0.1955 | 0.2463 |

| 0.750 | 0.109 | 6.88 | 0.532 | 0.2195 | 0.2223 |

| 0.750 | 0.120 | 6.25 | 0.510 | 0.2375 | 0.2043 |

| 0.875 | 0.020 | 43.75 | 0.835 | 0.0537 | 0.5476 |

| 0.875 | 0.028 | 31.25 | 0.819 | 0.0745 | 0.5268 |

| 0.875 | 0.035 | 25.00 | 0.805 | 0.0924 | 0.5090 |

| 0.875 | 0.049 | 17.86 | 0.777 | 0.1272 | 0.4742 |

| 0.875 | 0.065 | 13.46 | 0.745 | 0.1654 | 0.4359 |

| 0.875 | 0.083 | 10.54 | 0.709 | 0.2065 | 0.3948 |

| 0.875 | 0.095 | 9.21 | 0.685 | 0.2328 | 0.3685 |

| 0.875 | 0.109 | 8.03 | 0.657 | 0.2623 | 0.3390 |

| 0.875 | 0.120 | 7.29 | 0.635 | 0.2846 | 0.316L7 |

| 1.000 | 0.028 | 35.71 | 0.944 | 0.0855 | 0.6999 |

| 1.000 | 0.035 | 28.57 | 0.930 | 0.1061 | 0.6793 |

| 1.000 | 0.049 | 20.41 | 0.902 | 0.1464 | 0.6390 |

| 1.000 | 0.065 | 15.38 | 0.870 | 0.1909 | 0.5945 |

| 1.000 | 0.083 | 12.05 | 0.834 | 0.2391 | 0.5463 |

| 1.000 | 0.095 | 10.53 | 0.810 | 0.2701 | 0.5153 |

| 1.000 | 0.109 | 9.17 | 0.782 | 0.3051 | 0.4803 |

| 1.000 | 0.120 | 8.33 | 0.760 | 0.3318 | 0.4536 |

| 1.000 | 0.134 | 7.46 | 0.732 | 0.3646 | 0.4208 |

| 1.250 | 0.035 | 35.71 | 1.180 | 0.1336 | 1.0936 |

| 1.250 | 0.049 | 25.51 | 1.152 | 0.1849 | 1.0423 |

| 1.250 | 0.065 | 19.23 | 1.120 | 0.2420 | 0.9852 |

| 1.250 | 0.083 | 15.06 | 1.084 | 0.316L3 | 0.9229 |

| 1.250 | 0.095 | 13.16 | 1.060 | 0.3447 | 0.8825 |

| 1.250 | 0.109 | 11.47 | 1.032 | 0.3907 | 0.8365 |

| 1.250 | 0.120 | 10.42 | 1.010 | 0.4260 | 0.8012 |

| 1.250 | 0.134 | 9.33 | 0.982 | 0.4698 | 0.7574 |

| 1.500 | 0.035 | 42.86 | 1.430 | 0.1611 | 1.6061 |

| 1.500 | 0.049 | 30.61 | 1.402 | 0.2234 | 1.5438 |

| 1.500 | 0.065 | 23.08 | 1.370 | 0.2930 | 1.4741 |

| 1.500 | 0.083 | 18.07 | 1.334 | 0.3695 | 1.3977 |

| 1.500 | 0.095 | 15.79 | 1.310 | 0.4193 | 1.3478 |

| 1.500 | 0.109 | 13.76 | 1.282 | 0.4763 | 1.2908 |

| 1.500 | 0.120 | 12.50 | 1.260 | 0.5202 | 1.2469 |

| 1.500 | 0.134 | 11.19 | 1.232 | 0.5750 | 1.1921 |

| 1.500 | 0.148 | 10.14 | 1.204 | 0.6286 | 1.1385 |

| 1.750 | 0.035 | 50.00 | 1.680 | 0.1886 | 2.2167 |

| 1.750 | 0.049 | 40.82 | 1.902 | 0.3003 | 2.8413 |

| 1.750 | 0.065 | 26.92 | 1.620 | 0.3441 | 2.0612 |

| 1.750 | 0.083 | 21.08 | 1.584 | 0.4347 | 1.9706 |

| 1.750 | 0.095 | 18.42 | 1.560 | 0.4939 | 1.9113 |

| 1.750 | 0.109 | 16.06 | 1.532 | 0.5619 | 1.8433 |

| 1.750 | 0.120 | 14.58 | 1.510 | 0.6145 | 1.7908 |

| 1.750 | 0.134 | 13.06 | 1.482 | 0.6803 | 1.7250 |

| 1.750 | 0.148 | 11.82 | 1.454 | 0.7449 | 1.6604 |

| 1.750 | 0.165 | 10.61 | 1.420 | 0.8216 | 1.5837 |

| 2.000 | 0.035 | 57.14 | 1.930 | 0.2161 | 2.9255 |

| 2.000 | 0.049 | 40.82 | 1.902 | 0.3003 | 2.8413 |

| 2.000 | 0.065 | 30.77 | 1.870 | 0.3951 | 2.7465 |

| 2.000 | 0.083 | 24.10 | 1.834 | 0.4999 | 2.6417 |

| 2.000 | 0.095 | 21.05 | 1.810 | 0.5685 | 2.5730 |

| 2.000 | 0.109 | 18.35 | 1.782 | 0.6475 | 2.4941 |

| 2.000 | 0.120 | 16.67 | 1.760 | 0.7087 | 2.4328 |

| 2.000 | 0.134 | 14.93 | 1.732 | 0.7855 | 2.3561 |

| 2.000 | 0.148 | 13.51 | 1.704 | 0.8611 | 2.2805 |

| 2.000 | 0.165 | 12.12 | 1.670 | 0.9512 | 2.1904 |

Diameter Tolerance ASTM A269 Tube

| NPS | ASTM A269 Tube OD Tolerance | |||

| + | – | |||

| inch | mm | inch | mm | |

| 1/8~1 1 /2 > 1 1 /2~4 > 4~8 > 8~18 > 18~26 > 26~34 > 34~48 |

1/64(0.015) 1/32(0.031) 1/16(0.062) 3/32(0.093) 1/8(0.125) 5/32(0.156) 3/16(0.187) |

0.4 0.8 1.6 2.4 3.2 4.0 4.8 |

1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) |

0.8 0.8 0.8 0.8 0.8 0.8 0.8 |

| NPS | ASTM A269 Tube Tolerance, % | |

| + | – | |

| 1/8-2 1 /2 | 20.0 | 12.5 |

| 3~18, t/D≤ 5% | 22.5 | 12.5 |

| 3~18, t/D> 5% | 15.0 | 12.5 |

| ≥ 20, welded | 17.5 | 12.5 |

| ≥ 20, seamless, t/D≤ 5% | 22.5 | 12.5 |

| ≥ 20, seamless, t/D> 5% | 15.0 | 12.5 |

ASTM A249 requires extensive mechanical testing for use in critical environments in boilers or heat exchangers. ASTM A269 requires reverse flattening, plus flange and hardness tests. It does not require tensile testing. ... It does not require tensile or hardness testing

ASTM A249 and ASTM A269 specifications are two standards for Austenitic stainless steel tubes, there are the same requirements in technical, also they have some differences.

| Specification | ASTM A249 | ASTM 269 |

| Tube Manufacturing | Welded | Welded And Seamless |

| Application | Boiler Superheater Heat-Exchanger Condenser |

General Service |

| Sizes | OD: maximum 304.8 mm Wall Thickness: 0.4 – 8.1 mm |

Inside Diameter: minium 3.4 mm Wall Thickness: 0.51 mm |

| ASTM / ASME | ASTM A249 ASME SA249 |

ASTM A269 / A269M |

| Test | Flange Test | Flange Test |

ASTM A249 and ASTM A269 Specifications indicate tube material is Austenitic Stainless Steel grades, which is wide used in stainless steel families, TP304, TP304L, TP316, TP316L, TP347, TP347H, TP321, TP321H, 904L grade is ideal material for various applications, they have some advantages that other steels do not have.

However, in some cases, Ferritic Stainless Steel Grade and Duplex stainless steel tubes are produced to comply with A249 or A269 standard, Ferritic steel tubes can reduce cost, and duplex steel tubes increase strength and longevity.

Usually, ASTM A249 tubing sizes and wall thickness separately are 1/8 in (3.2 mm) in inside diameter to 12 in (304.8 mm) in outside diameter and 0.015 in to 0.32 in (0.4 – 8.1 mm). The tubing sizes and thicknesses furnished to ASTM A269 are 1/4 in. (6.4 mm) in inside diameter and larger and 0.020 in. (0.51 mm) in nominal wall-thickness and heavier.

Tube size is stated in inch or millimeter, sometimes, Tube gauge size (BWG) is specified.

ASTM A249 welded tube and ASTM A269 Tubing dimensional tolerance are in accordance with ASTM A1016 specification, difference as below:

| Specification | Outside Diameter | Outside Diameter | Wall Thickness | Length |

| A249 | <25.40mm | ±0.10mm | ±10.00% | OD<50.8mm (-0, +3.0mm) OD≥50.8mm (-0, +5.0mm) |

| A249 | ≥25.4mm~38.1mm | ±0.15mm | ±10.00% | OD<50.8mm (-0, +3.0mm) OD≥50.8mm (-0, +5.0mm) |

| A249 | ≥38.1mm~50.8mm | ±0.20mm | ±10.00% | OD<50.8mm (-0, +3.0mm) OD≥50.8mm (-0, +5.0mm) |

| A249 | ≥50.8mm~63.5mm | ±0.25mm | ±10.00% | OD<50.8mm (-0, +3.0mm) OD≥50.8mm (-0, +5.0mm) |

| A249 | ≥63.5mm~76.2mm | ±0.30mm | ±10.00% | OD<50.8mm (-0, +3.0mm) OD≥50.8mm (-0, +5.0mm) |

| A249 | ≥76.2mm~101.6mm | ±0.38mm | ±10.00% | OD<50.8mm (-0, +3.0mm) OD≥50.8mm (-0, +5.0mm) |

| A249 | ≥101.6mm~190.5mm | +0.38mm -0.64mm | ±10.00% | OD<50.8mm (-0, +3.0mm) OD≥50.8mm (-0, +5.0mm) |

| A249 | ≥190.5mm~228.6mm | +0.38mm -1.14mm | ±10.00% | OD<50.8mm (-0, +3.0mm) OD≥50.8mm (-0, +5.0mm) |

| A269 | <38.1mm | ±0.13mm | OD<12.7mm ±15% OD≥12.7mm ±10% |

OD<38.1mm (-0, +3.20mm) OD≥38.1mm (-0, +4.80mm) |

| A269 | ≥38.1mm~88.9mm | ±0.25mm | OD<12.7mm ±15% OD≥12.7mm ±10% |

OD<38.1mm (-0, +3.20mm) OD≥38.1mm (-0, +4.80mm) |

| A269 | ≥88.9mm~139.7mm | ±0.38mm | OD<12.7mm ±15% OD≥12.7mm ±10% |

OD<38.1mm (-0, +3.20mm) OD≥38.1mm (-0, +4.80mm) |

| A269 | ≥139.7mm~203.7mm | ±0.76mm | OD<12.7mm ±15% OD≥12.7mm ±10% |

OD<38.1mm (-0, +3.20mm) OD≥38.1mm (-0, +4.80mm) |

| A269 | ≥203.7mm~304.8mm | ±1.01mm | OD<12.7mm ±15% OD≥12.7mm ±10% |

OD<38.1mm (-0, +3.20mm) OD≥38.1mm (-0, +4.80mm) |

| A269 | ≥304.8mm~355.6mm | ±1.26mm | OD<12.7mm ±15% OD≥12.7mm ±10% |

OD<38.1mm (-0, +3.20mm) OD≥38.1mm (-0, +4.80mm) |

Tube Type ( Manufacture Process)

ASTM A249 indicate welded tubes, the tubes should be cold worked or cold drawn method, prior to final heat treatment. ASTM A269 tubes should be welded type or seamless type, which is made in cold finished or hot finished.

Tube Surface

Both ASTM A249 and ASTM A269 specifications, after heat treatment, tubes should be pickled free of scale, when bright annealing is used, pickling is not necessary.

Heat Treatment

All the tubes under ASTM A249 and ASTM A269 standards should be heat treated condition unless in special condition, there are different annealing temperatures for different materials.

Mechanical Properties

Nondestructive Test

Each tube should be conducted to the nondestructive test or the hydrostatic test, in many cases, nondestructive test refer to eddy current test or air underwater test.

Dual Certification Standard

Users should distinguish between ASTM A249 and ASTM A269 specification, although they are typical standards for stainless steel tube technical requirement, but different.

In some cases, users require stainless steel tube conform to dual certified standard A249/A269, it means the tubes should comply to both ASTM A249 and ASTM A269, and get best value or result specified in the two specifications, the tubes will be high quality.

ASME SA249 is the same standard with ASTM A249 specification, ASME SA-249 is published by ASME, but ASME have no equivalent standard with ASTM A269.

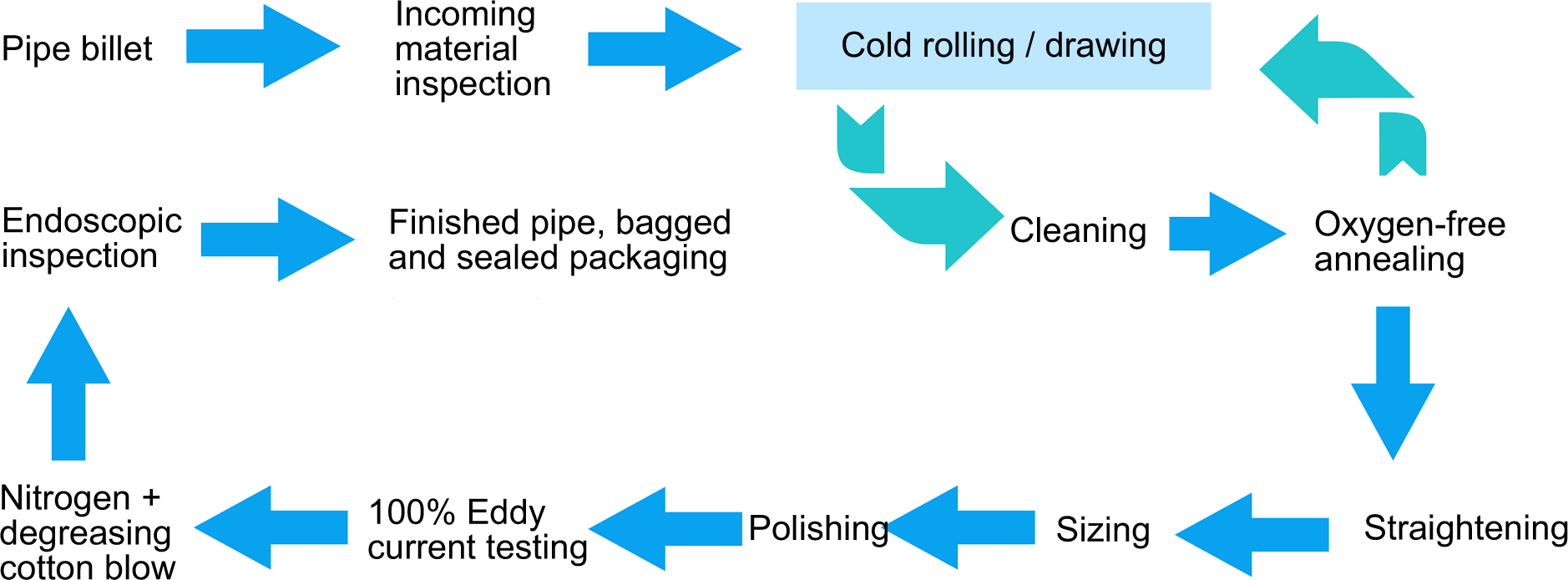

A new type of stainless steel seamless pipe cold drawing processing equipment that can draw pipes of different specifications to meet various requirements. Our factory has 14 cold drawing machines.

Applying tensile force to metal material to obtain a plastic molding method through the die with the same size and shape of the die hole is called drawing. Drawing is one of the main production methods for pipes. The stainless steel pipes produced by drawing are dimensionally accurate and have a smooth surface.

Main function is to remove the grease produced by the previous cold processing operation, achieving the high-quality standard requirements of the pipe material.

To eliminate the stress generated after cold working deformation of stainless steel pipes, and to obtain satisfactory microstructure. The annealing equipment is a continuous bright annealing furnace for stainless steel, mainly used for heat treatment of stainless steel products in a protective atmosphere.

A device used for straightening pipe material. Once the product is bitten by the rollers, it continuously performs linear or rotational movements, thereby subjecting the product to various deformations such as compression, bending, and flattening, ultimately achieving the purpose of straightening.

A machine used for polishing the external surface of finished pipes to achieve a more uniform surface quality.

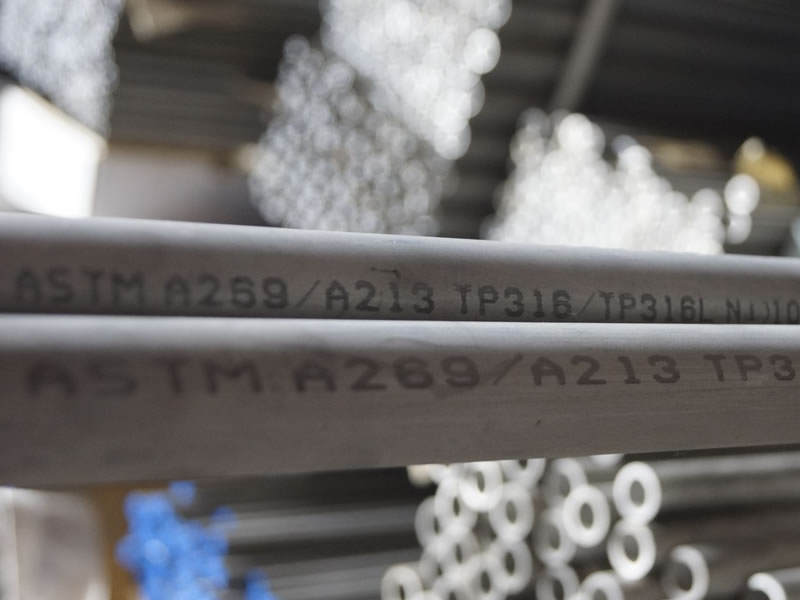

ASTM A269 TP316L stainless tube refers to a specific type of stainless steel tubing that conforms to the ASTM A269 standard and is made from grade TP316L stainless steel.

The ASTM A269 TP316 stainless tubes undergo a comprehensive quality assurance process, including underwater ultrasonic testing, eddy current testing, borescope inspection, spectroscopy, and roughness testing.

The terms AP, MP, BA, and EP refer to different surface finishes or treatments applied to the stainless steel.

These finishes are essential in various industries where the appearance, corrosion resistance, and cleanliness of the stainless steel are critical. Here's an explanation of each term:

EP stands for electropolished, a process where the stainless steel tube, after annealing and acid pickling, undergoes electropolishing using electrodes and acid in a tank, creating a chemical reaction to achieve a clean surface through electrochemical polishing. EP tubes are used in pipeline projects with high cleanliness requirements for the stainless steel tube surface.

AP refers to the condition where the surface of the stainless steel tube is treated after annealing through acid pickling to remove the oxide layer. Stainless steel industrial pipes sold in the market, known for their wide applications, are extensively used in the chemical industry for pipeline needs.

MP denotes a stainless steel seamless tube that undergoes mechanical polishing after annealing and acid pickling to achieve a bright and clean surface. This finish is primarily utilized in the pharmaceutical and food industries.

BA is specific to precision-rolled stainless steel tubes. Also known as precision tubes, BA tubes skip the regular annealing and acid pickling process after semi-finished rolling. Instead, they use argon gas in a vacuum annealing furnace to remove surface oil stains generated during the rolling process, preserving the brightness of the surface without leaving an oxide layer.

These surface finishes cater to various industry requirements, offering different levels of brightness, cleanliness, and corrosion resistance based on specific applications.

The versatility of ASTM A269 lends itself to a wide array of applications across various industries:

In aggressive chemical environments, where corrosion resistance is paramount, ASTM A269 stainless steel tubes find applications in transporting and containing corrosive fluids and gases.

Pharmaceutical industries demand hygienic and sterile environments. Stainless steel tubes complying with ASTM A269 are utilized in processes involving high-purity fluids and gases.

For the safe transport of food and beverages, ASTM A269 tubing ensures that no contaminants leach into consumable products.

Stainless steel BA pipe, bright annealing pipe, seamless pipe, gas pipe, clean pipe, bushing, high purity gas pipe.

Material: 304 precision stainless steel pipe,316L standards are ASTM A249, A269, A270, 3A, and BPE standard, G3459. JIS G3447.

Forming method: mainly multi-roll cold rolling, the dimensional accuracy of the product can reach 0.2%, and the internal surface finish of the product Ra< 0.45um.

Stainless steel EP (Electropolished) pipes are highly refined stainless steel tubes designed for high-purity applications, particularly in industries that demand the highest levels of cleanliness, such as semiconductor, pharmaceutical, and food and beverage industries.

Material: 304 precision stainless steel pipe,316L standards are ASTM A249, A269, A270, 3A, and BPE standard, G3459. JIS G3447.

Product features: accurate size, overall clean, smooth surface, the inner surface is not polished better than a polished finish Raw materials: Special requirements can be used twice furnace ingot, meet ASTM A269 standard.

Stainless steel AP (Annealed & Pickled) pipes are high-quality stainless steel tubes that have undergone annealing and pickling processes to improve their performance characteristics.

These processes enhance the corrosion resistance and surface finish of the pipes, making them suitable for various industrial applications.

Manufacturing method: cold rolling + fine drawing, dimensional accuracy of about 0.05mm, inner surface Ra0.4 micron. Heat treatment: bright solution (annealing) under the protection of reducing atmosphere.

Our duplex stainless steel seamless pipes are produced using a combination of hot rolling perforation and cold rolling processing, with cold drawing as an auxiliary process.

From hot rolling perforation of raw materials to cold rolling processing, using the domestic leading mill as the main, cold drawing as the auxiliary common process to organize production.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.