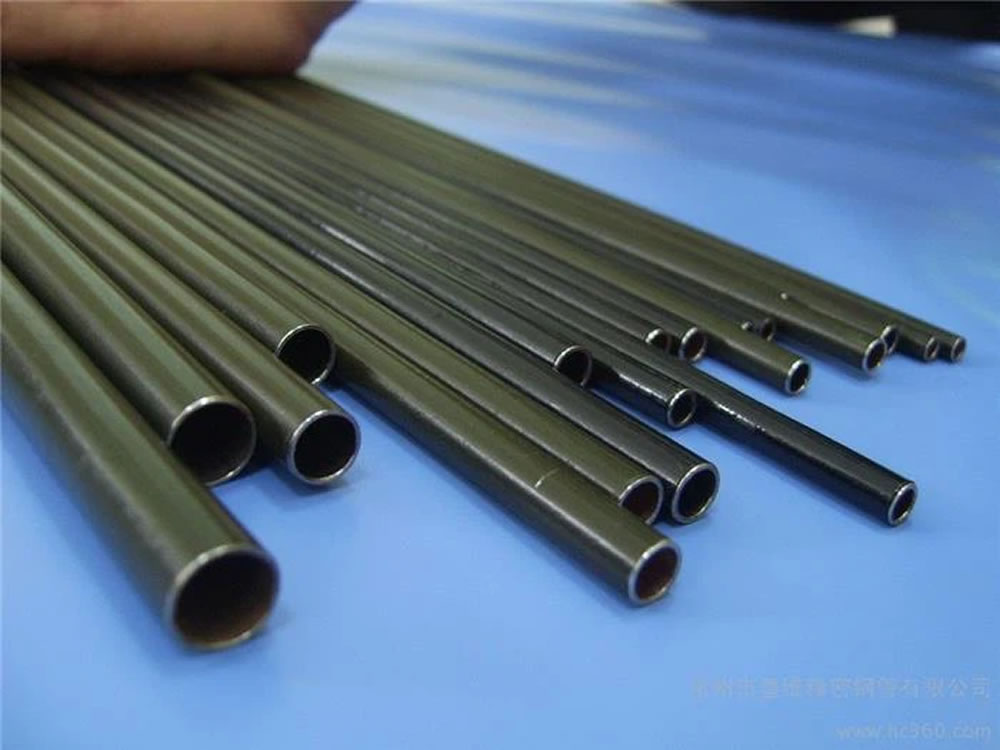

Galvanized mild steel pipe

Mild Steel Pipe Galvanized is a tubular shaped pipe of galvanized Mild Steel.

Galvanized seamless tube refers to a type of steel tube that has been coated with a layer of zinc to provide corrosion resistance.

The tubes are first manufactured through a seamless process, ensuring a smooth and continuous structure.

Galvanized seamless tubes offer several advantages. The zinc coating provides excellent corrosion resistance, extending the lifespan of the tube and reducing maintenance requirements. The seamless construction ensures a strong and leak-resistant tube, suitable for high-pressure applications. Additionally, galvanized seamless tubes are relatively easy to install and can withstand harsh environmental conditions.

Galvanized seamless tubes are widely used in various industries, including construction, plumbing, automotive, and infrastructure projects. They are commonly used for water supply systems, gas pipelines, structural supports, and outdoor applications where corrosion resistance is essential.

In general, Galvanized seamless tube is the hot dip galvanized and electro-galvanized two categories.

The first to introduce hot-dip galvanizing, including wet, dry the, lead, zinc, oxidation-reduction method, etc., the process is very complex, the need for technical maturity to complete. Steel Pipe acid leaching after cleaning, the specific method used to activate the surface of the tube improve the quality of zinc, is not the same, hot dip galvanized main difference.

I do not know understand if understand the electro-galvanized zinc coating surface and compared to a very smooth and dense, homogeneous; the characteristics of the electro-galvanized with good corrosion resistance and mechanical properties; Production is now mainly used in dry and oxidation-reduction method. Coating on one side, the internal and external surfaces of the thickness of the coating on different double-sided smooth coating, and thin-walled tube galvanized to complete this method.

Zinc consumption 60% to 75% lower than the hot-dip galvanizing. Electro-galvanized in the operation of technical and general than there is a certain complexity, which requires high technology and conditions in order to complete.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.