These tubes typically possess high strength, good toughness, and excellent thermal conductivity, making them suitable for transferring heat in such applications.

The heat treatment of cold-drawn special-shaped steel tubes is a critical step in achieving the desired balance of mechanical properties and dimensional stability. By carefully controlling the heat treatment process, manufacturers can produce high-quality steel tubes suitable for a wide range of demanding applications.

Seamless cold-drawn low carbon steel tubes for use in heat exchangers and condensers" refers to tubes specifically designed for the manufacturing of heat exchangers and condensers. These tubes typically possess high strength, good toughness, and excellent thermal conductivity, making them suitable for transferring heat in such applications.

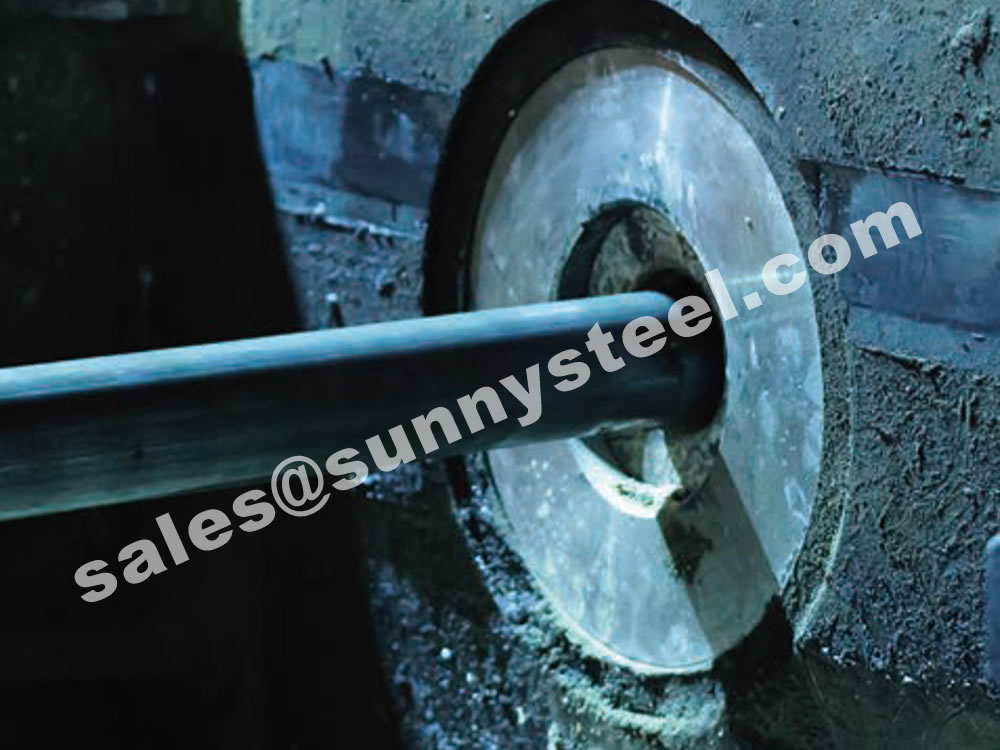

These tubes undergo a cold-drawing process to ensure precise dimensions and a smooth surface finish. The choice of low carbon steel is often due to its excellent workability, high weldability, and suitability for a range of temperature and pressure conditions.

When using these tubes, it is crucial to ensure compliance with relevant industry standards and specifications to meet the specific requirements of the application. This may include adherence to standards regarding chemical composition, mechanical properties, dimensional accuracy, and corrosion resistance.

Cold drawing is a metal forming process that allows manufacturers to produce high precision special-shaped steel tubes. This process can significantly enhance the mechanical properties of the steel tubes, making them suitable for various applications where high strength and dimensional accuracy are required.

Heat treatment plays a crucial role in determining the final properties of cold-drawn special-shaped steel tubes. It can:

The heat treatment processes commonly used for cold-drawn special-shaped steel tubes include:

The microstructure of steel tubes can be significantly altered through heat treatment. This can include:

When selecting the appropriate heat treatment process for cold-drawn special-shaped steel tubes, it is essential to consider the specific application requirements. These may include:

After heat treatment, the steel tubes must undergo rigorous quality control and testing to ensure they meet the required specifications. This includes:

With years of expertise, we provide a diverse array of steel tube processing options. From sawing and machining tube blanks to intricate bending and upsetting operations, we actively assist you throughout your projects.

Our capabilities extend to eccentricity reduction and concentricity enhancement through turning and grinding. We excel in creating complex geometries using processes like rotary swaging and axial forming. Additionally, we offer property modifications via partial heat treatment, ensuring tailored solutions for your specific needs.

Variable wall thicknesses

Drilling / stamping / lasering

Peeling / roller burnishing

Cold forming

Cutting

Beveling

Deburring

Thread rolling / threading

Partial hardening

Turning / milling / grinding

Reducing / expanding

Swing

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.