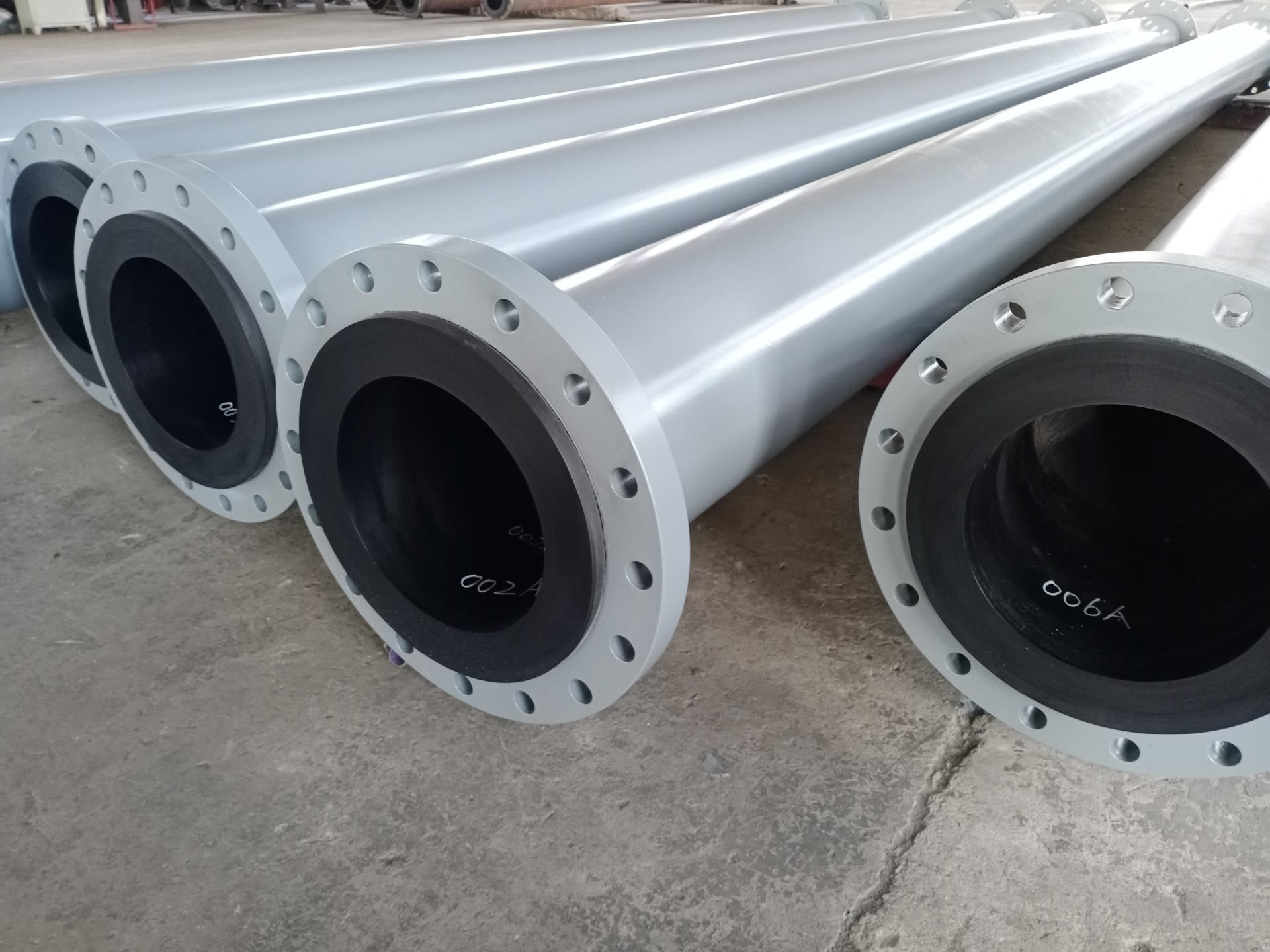

UHMWPE Lined Steel Pipe

Steel pipes with UHMWPE lining for enhanced corrosion and abrasion resistance.

UHMWPE (Ultra-High Molecular Weight Polyethylene) pipe offers exceptional durability, high strength-to-weight ratio, and resistance to abrasion, corrosion, and chemicals. Ideal for various industries like power generation, mining, and chemical processing.

Basalt tile lined pipes are used in industries such as power generation, mining, cement, steel, and chemical processing for abrasive material transportation.

UHMWPE is produced by co - extruding materials with an average molecular weight of 3.5 - 9.2 million under high temperature and high pressure through an extruder.

UHMWPE Pipe has excellent properties: 15 times more wear - resistant than steel, 8 times lighter, with a 5 - times lower friction coefficient and 1/10 the pressure loss of steel pipes. It's suitable for various applications like powder and coal ash transportation in thermal power systems, tailings and mud transportation in mining, and more.

UHMWPE is more durable and abrasion - resistant than HDPE. Its long polymer chains make it harder to wear down and can outlast HDPE up to 10 times in high - wear situations. However, HDPE is easier to machine or weld.

Low Melting Point: Limits use in high - temperature applications.

Limited UV Resistance: Susceptible to degradation under prolonged sunlight.

Difficult to Bond: Requires special treatments or adhesives for bonding.

Limited Wear Resistance in Abrasive Environments: May not perform as well as ceramics or certain metals.

Not Suitable for High Load Bearings: Low modulus of elasticity can cause deformation under heavy loads.

Difficult to Machine: High molecular weight and low thermal conductivity require special tools.

Sensitive to Oxidation: Can lead to reduced mechanical properties at elevated temperatures.

Water Absorption: May affect mechanical properties and dimensional stability.

Despite these, UHMWPE is still valuable for applications where its unique properties are beneficial.

The choice depends on the application. UHMW is better for industrial applications with friction or wear concerns, while HDPE is preferred for items shaped by welding or 3D printing, like chemical - holding tanks.

Ultra-high molecular weight polyethylene pipe has superior performance over conventional HDPE pipe such as very high wear resistance, impact resistance, excellent resistance to internal pressure strength, resistance to environmental stress cracking, intrinsically self-lubricating, anti-adhesion, low temperature resistance and excellent chemical resistance.

Ultra-high molecular weight polyethylene (UHMW full name is ultra-high molecular weight polyethylene pipe) is a thermoplastic engineering plastics with an average molecular weight greater than 1.5 million, which is polymerized by ethylene and butadiene monomer under the action of a catalyst.

Ultra-high-molecular-weight polyethyene (UHMWPE,UHMW is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene, (HMPE) it hasextremely ong chains, with a mo ecular mas usually between 3.5 and 7.5 mllon amu. The loner chain serves to traster oad more eflectively to the polymer backboneby strenothening intermolecular interactions. This results in a very tough matera, with the highest impact strength of any thermoplastic presently made.UHMWPE is odories, tasteless, and nontoxic.t embodles al the characteristics of hioh-density polyethylene (HDPE with the added traits of being resistant toconcentrated acids and aka ls,as wel as numerous oroanic so vents. t is hichy resstant to corosve chemicas except oxidizina acids: nas extremey ow moisturebosorption and a very ow coeticent of friction: is self-ubricating see boundary ubrication; and is hiny resistant to abraso, in some torms being 15 times moreesstant to abrason han caron stee. s ce cent of rcton s son tcanty ower than that o nwon and arela and s comnarahe to that at nowtetratuornetnuene(PTFE, Teflon), but UHMWPE has better abrasion resistance than PTFE.

Ultrahigh-molecular-weight polyethylene (UHMWPE) has been the material of choice for the polymeric component in total joint replacements primarily because of its excellent combination of wear resistance, structural strength and biocompatibility and remains the gold standard thus far. Nevertheless, wear of UHMWPE prostheses produces billions of submicron particles annually,1 which may cause a foreign-body response, leading to extensive bone resorption and gross loosening of the implants.2–5 UHMWPE wear is of particular concern for young or active patients who may face one or more revisions with accumulative bone loss in their lifetime. Thus, improving the wear resistance of UHMWPE and, thereby, reducing the volume of wear particles released to the periarticular tissues should reduce the adverse biological responses and substantially extend the clinical lifespan of total joint replacements.

Ultra-high molecular weight polyethylene is a polymer compound, which is difficult to process, and has excellent wear resistance, self-lubricating properties, high strength, stable chemical properties, and strong anti-aging properties. When it comes to ethylene, be sure to pay attention to these characteristics. The specific methods are as follows:

Due to its many excellent properties, UHMWPE has shown great advantages in the high performance fiber market, from mooring ropes in offshore oil fields to high performance lightweight composites, in modern warfare and aviation, Aerospace, marine defense equipment and other fields play a pivotal role.

The specifications of Ultra-High Molecular Weight Polyethylene (UHMWPE) pipes can vary based on the manufacturer, application, and specific requirements. However, here are some common specifications that are often associated with UHMWPE pipes:

| DN mm |

Wall thickness (mm) | |||||

|---|---|---|---|---|---|---|

| 0.6Mpa | 0.8Mpa | 1.0Mpa | 1.25Mpa | 1.6Mpa | 2.0Mpa | |

| 65 | 8 | 9 | ||||

| 96 | 9 | 10 | ||||

| 110 | 8 | 10 | ||||

| 130 | 8 | 10 | 12 | |||

| 159 | 10 | 12 | 15 | |||

| 168 | 8 | 10 | 13 | 16 | ||

| 205 | 8 | 10 | 12 | 15 | 18 | |

| 219 | 9 | 11 | 13 | 16 | 20 | |

| 236 | 10 | 12 | 14 | 18 | 22 | |

| 250 | 10 | 12 | 15 | 19 | 23 | |

| 273 | 9 | 11 | 13 | 16 | 21 | 25 |

| 280 | 9 | 11 | 14 | 17 | 21 | 26 |

| 300 | 10 | 12 | 15 | 18 | 23 | 27 |

| 315 | 10 | 12 | 15 | 19 | 24 | 29 |

| 325 | 10 | 13 | 16 | 19 | 24 | 30 |

| 350 | 11 | 14 | 17 | 21 | 26 | 32 |

| 377 | 12 | 15 | 18 | 22 | 28 | 35 |

| 400 | 12 | 16 | 19 | 24 | 30 | 36 |

| 415 | 13 | 16 | 20 | 25 | 31 | |

| 426 | 13 | 17 | 20 | 25 | 32 | |

| 536 | 16 | 21 | 26 | 23 | ||

| 560 | 16 | 22 | 27 | 33 | ||

| 630 | 19 | 25 | 30 | 37 | ||

| 652 | 20 | 26 | 32 | 38 | ||

| 710 | 21 | 27 | 34 | |||

| 800 | 23 | 31 | 38 | |||

Custom sizes available, where moulds already exist from 20-1400mm OD, up to 65 WT. Product can be manufactured in any colour, and to all conformance requirements.

UHMWPE has high wear-resistance, toughness, durability, and biocompatibility. Compare with existing plastic pipes, Wear resistant UNMWPE pipe has the most excellent wear resistance which is 4 to 7 times that of Q235 steel pipe and 2.7 times that of wear-resistant steel 16Mn. Therefore it increases pipe flow rate and improves the transmission efficiency of more than 20%. The working life of UHMWPE pipes is more than 3 times that of wear-resistant steel pipe.

UHMWPE pipes are widely used in the industries of dredging, mining, metallurgy, electric power, oil, textile, paper, food, chemical, mechanics, gas, tunneling ect.

Mining tailings pipe is the tailings slurry discharged from non-ferrous metal ore beneficiation and ferrous metal ore beneficiation, which needs to be transported to the tailings inventory.

UHMWPE has the following impressive statistics: up to 15 times the abrasion resistance of steel while being 8 times lighter than steel and having 5 times lower coefficient of friction than steel and offering as low as 1/10 the pressure loss of steel pipes.

UHMWPE has the following impressive statistics: up to 15 times the abrasion resistance of steel while being 8 times lighter than steel and having 5 times lower coefficient of friction than steel and offering as low as 1/10 the pressure loss of steel pipes.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.