Bimetallic Composite Pipe

Read more

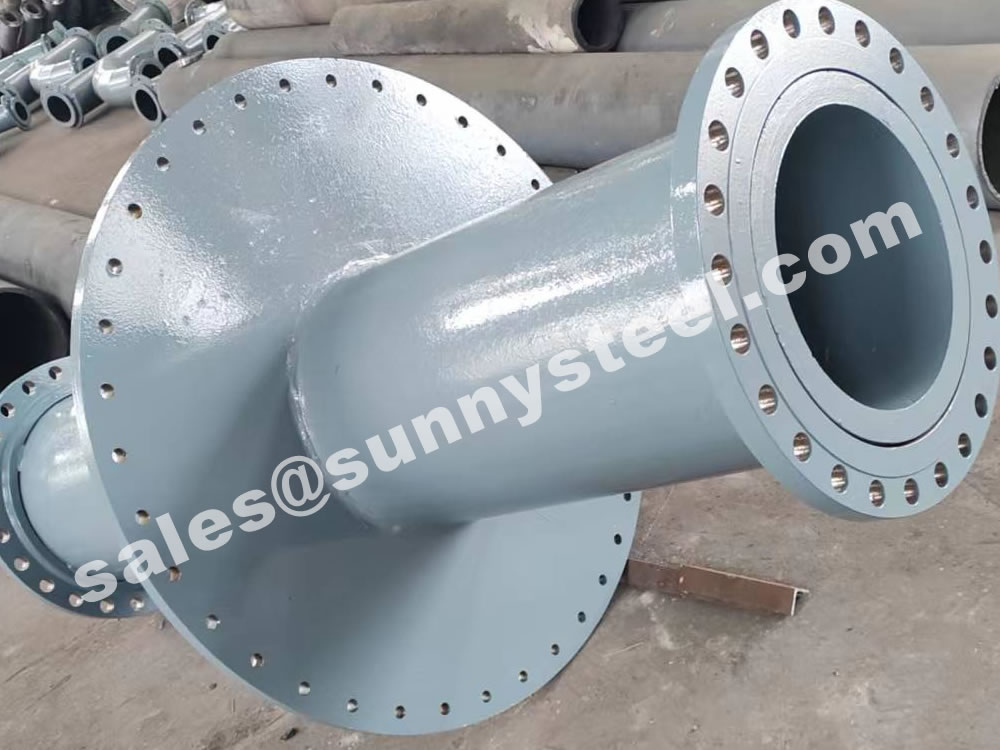

Ni-Hard Wearback Pipes are engineered for exceptional durability, specifically designed to withstand abrasive materials such as sand, cement, quarry dust, granite dust, sinter dust, slag, coal, and more.

Offering superior wear resistance, these pipes minimize wear on pipe bends compared to conventional materials.

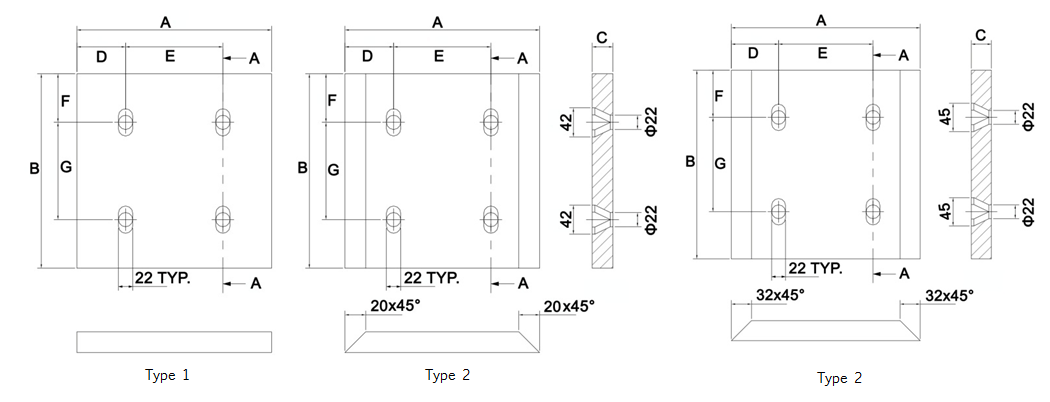

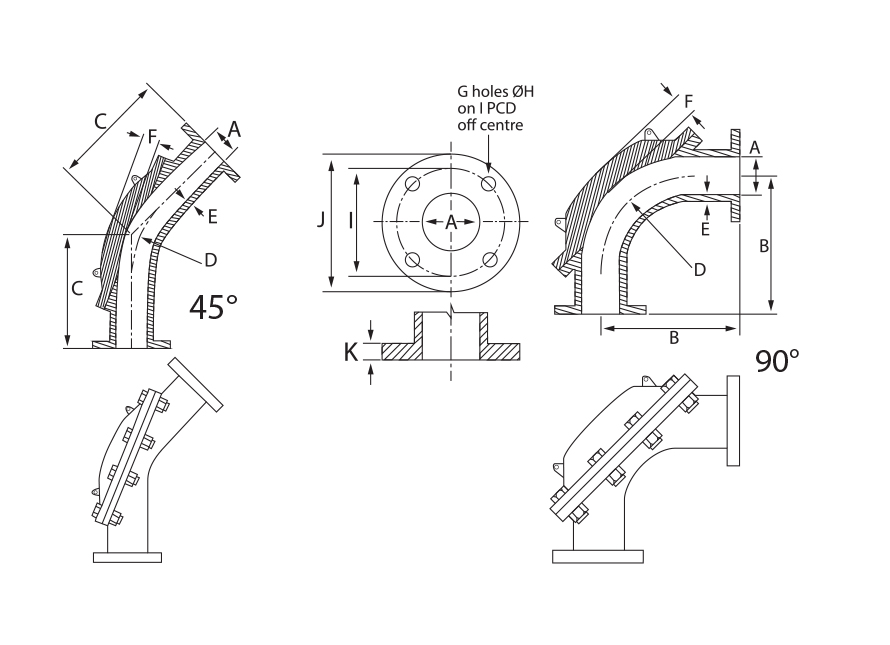

Our range includes standard and special radius plain bends, available with or without replaceable wear-back plates. Featuring standard flanged ends, Ni-Hard Wearback Pipes ensure efficient conveying of abrasive materials. Custom designs can be tailored to meet specific requirements.

Ni-Hard is a generic name for white cast iron, alloyed with Ni, Cr, Mo, and having extremely high strength, abrasion, corrosion resistance, fracture resistance, and toughness. The alloy is best suited to applications in mining, minerals and the iron processing industries.

Ni-Hard Wearback Pipes find widespread application in scenarios involving abrasive materials such as sand, cement, ores, and more. Whether in mining, construction, or industrial conveying, these pipes showcase versatility and applicability, offering reliable solutions for various applications.

Ni-Hard pipeis used for abrasion resistant applications where there is extreme temperature. It is used for handling coal fly ash in thermal power plant. Our Ni-hard pipe offers excellent abrasion resistant propertiesin extreme high temperature environment.High content of nickel in our Ni-hard pipe promotes austenite grain formation which causes these pipes to become abrasion and heat resistant.

We manufacture Ni-hard pipein various size and dimension. Weight of each Ni-hard pipe manufactured by us can range from25 kgs. to upto 500 kgs. single piece. We accept large quantity order for Ni-hardpipes. Ni-hard pipe is manufactured as per IS : 4771 – 1985 type 1A to upto type 3

Ni-Hard is a generic name for white cast iron alloyed with Ni, Cr, Mo, which has extremely high strength, abrasion resistance, corrosion resistance, fracture resistance and toughness. The alloy is best suited for applications in the mining, minerals and iron processing industries. It is ideal for metalworking rolls, mill liners, pulveriser rings, slurry pump parts, grinding media, impact bars, etc.

| Material | Grade or class | C | Si | Mn | S | P | Ni | Cr | Mo | Cu | Hardness max, HB |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Abrasion Resistant Iron | I-A | 2.80-3.60 | 0.8 | 2 | 0.15 | 0.3 | 3.3-5.0 | 1.4-4.0 | 1 | 550min | |

| Abrasion Resistant Iron | I-B | 2.40-3.00 | 0.8 | 2 | 0.15 | 0.3 | 3.3-5.0 | 1.4-4.0 | 1 | 550min | |

| Abrasion Resistant Iron | I-C | 2.50-3.70 | 0.8 | 2 | 0.15 | 0.3 | 4 | 1.0-2.5 | 1 | 550min | |

| Abrasion Resistant Iron | I-D | 2.50-3.60 | 2 | 2 | 0.15 | 0.1 | 4.5-7.0 | 7.0-11.0 | 1.5 | 500min | |

| Abrasion Resistant Iron | II-A | 2.00-3.30 | 1.5 | 2 | 0.06 | 0.1 | 2.5 | 11.0-14.0 | 3 | 1.2 | 550min |

| Abrasion Resistant Iron | II-B | 2.00-3.30 | 1.5 | 2 | 0.06 | 0.1 | 2.5 | 14.0-18.0 | 3 | 1.2 | 450min |

| Abrasion Resistant Iron | II-D | 2.00-3.30 | 1.5 | 2 | 0.06 | 0.1 | 2.5 | 18.0-23.0 | 3 | 1.2 | 450min |

| Abrasion Resistant Iron | III-A | 2.00-3.30 | 1.5 | 2 | 0.06 | 0.1 | 2.5 | 23.0-30.0 | 3 | 1.2 | 450min |

NiHard is a well-established white iron product alloyed with nickel and chromium to provide significant abrasion and impact resistance.

Our Ni Hard products include billets and liner plates that can be made to the customers’ specification or supplied from our range of stock sizes.

Our NiHard products include billets and liner plates, which can be customized to customers' specifications or supplied from our range of stock sizes. We can tailor NiHard products to meet any situation, regardless of size and shape concerns. Additionally, we offer cut and shaped liners for strategic placement on fixed plant equipment, enabling the creation of a unique wear package that maximizes wear life. NiHard is ideal for chutes, drop boxes, bins, and hopper liners.

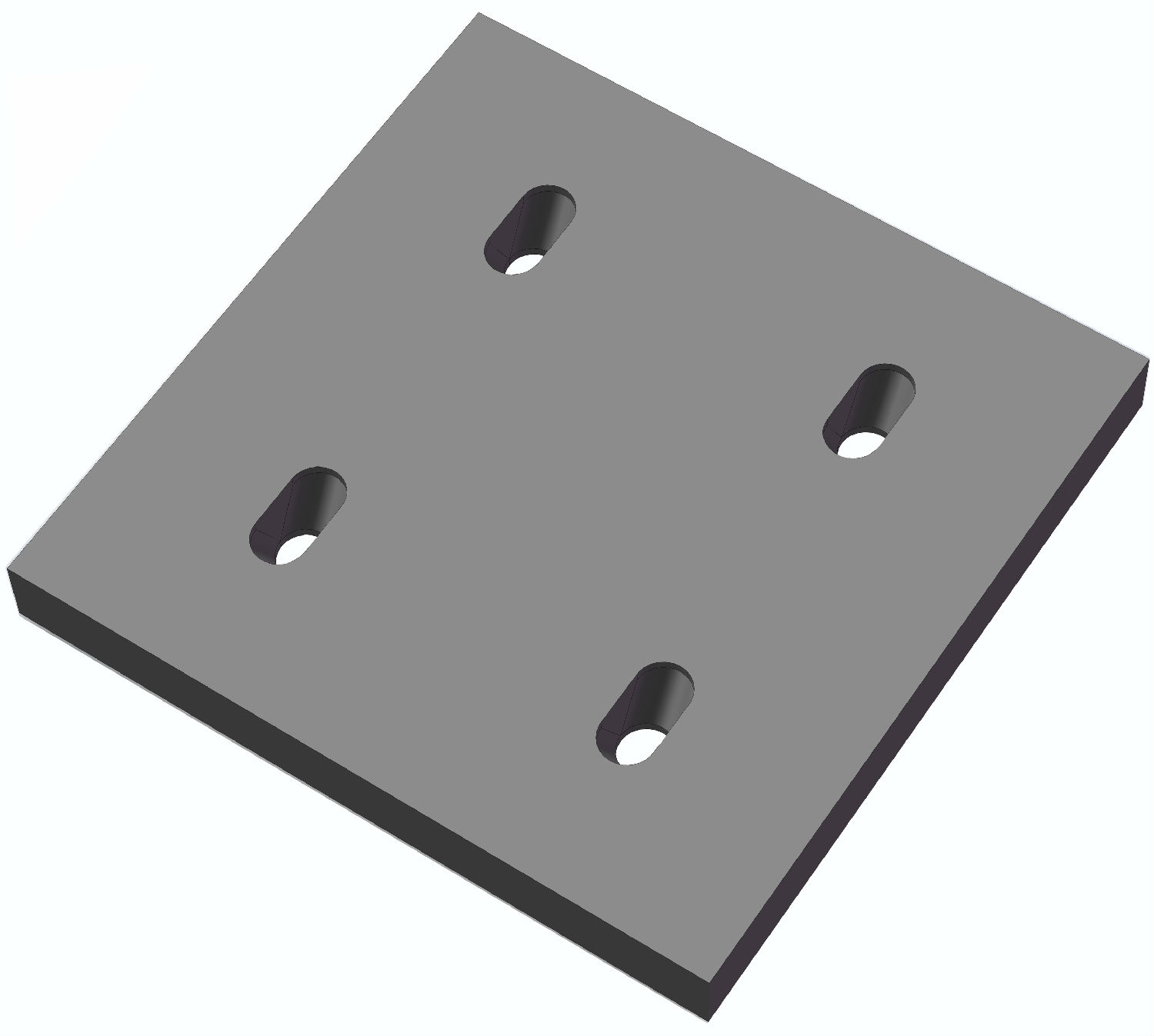

Ni-Hard wear plates are suitable for a variety of demanding applications where abrasion resistance and resistance to heavy surface pressure are crucial. These applications include chute liners, mill liners, hoppers, and deflector plates.

Ni-Hard is a white cast iron product alloyed with nickel and chromium to produce hard chromium carbides within a martensitic matrix. This structure makes Ni-Hard suitable for products operating in high-abrasive and high-impact conditions.

We primarily supply cast billets and liner plates produced to NiHard 4 specifications. However, we can produce billets and liner plates from the following alloys upon special request:

NiHard is a well-established white iron product alloyed with nickel and chromium to give significant abrasion and impact resistant properties.

Ni-hard cast iron wear plates are high-performance white cast iron products enhanced with nickel and chromium.

We specialize in manufacturing Ash Bends, which are specially coated with Ni-Hard. Ni-Hard is a metal with chrome content of 1.4% to 28%. It is an abrasive iron for low and high stress abrasion in Mining, Milling, and Earth Handling uses. Ni-hard is best in preventing abrasion in bends. Our range of Ni-Hard Ash Bends has shown excellent performances and has good wear & tear.

To cope with a whole list of abrasive materials including sand, cement, quarry dust, granite dust, sinter dust, slag, coal and many others which cause extra wear on pipe bends of conventional material, we provide a range of Ni-Hard castings. Standard and special radius plain bends with and without replaceable wear-back plates are available. Flanged ends as standard, although special designs can be considered. Ni-Hard bends are essential for the efficient conveying of abrasive materials.

Ni-Hard and Chrome White Iron are both commonly used materials in applications requiring high wear resistance, but they have several key differences:

Ni-hard |

High Chrome White Iron |

| Specification: ASTM A532 Class I | Specification: ASTM A532 Class II and III |

| Microstructure: Cementitic iron that solidifies as austenite with Fe3C carbides | Microstructure: Solidifies through the eutectic point, forming an iron-rich metallic phase (that is mostly martensite) along with M7C3 chromium carbides |

| Ni-hard Type A is the least expensive of the Ni-hard alloys, and the most common. It is usually specified for use when combating abrasion only. | When impact is an issue, it is better to select a high chrome white iron. Class II alloys are considered to have the highest toughness of the chrome white iron alloys. |

| Ni-hard Type B can replace Type A if more toughness is required. | Again, the chrome white iron class II alloys will have a higher toughness than Ni-hard A, B or D. Plus, the high chrome white iron will be more corrosion resistant. |

| Ni-hard Type D is the toughest of the Ni-hard grades, as well as the most corrosion resistant. It is, however, also the most expensive. | The high chrome white iron class III alloys have the highest level of chromium.They are the most corrosion resistant of the ASTM A532 alloys. Their toughness is slightly less than the class II alloys, but higher than the Ni-hard alloys. |

| Applications Type A is for low cost parts that are not exposed to high dynamic stresses:

|

Applications Class II is for parts subjected to a high level of impact:

|

Ni-hard is also called ASTM A532 Class I Type A. This blog explores the differences between Ni-hard and ASTM A532 Class II and III in an easy-to-read chart form. Microstructure differences will be examined and application suggestions made.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.