UHMWPE Lined Steel Pipe

Steel pipes with UHMWPE lining for enhanced corrosion and abrasion resistance.

A UHMWPE (Ultra-High Molecular Weight Polyethylene) lined steel pipe is a type of pipeline where the interior surface of the steel pipe is lined with a layer of UHMWPE material.

Download PDFUHMWPE lined steel pipe also named high wear resistant PE-steel composite pipe, it is combined by carbon steel UHMWPE pipeline through special technical method, and the diameter of the composite pipe is available from DN200~DN1200.

With the lining thickness of 8mm -20mm, the UHMWPE steel composite pipe not only make full use of the excellent properties of UHMWPE,it also can adapt high pressure, enhance the long distance fieldwork transmission, effectively prevent external destruction,filling the domestic gap in the field of composite pipe, expand the application area

| Outer steel pipe | Inner uhmwpe pipe | Uhmwpe-steel composited pipe | |||||

|---|---|---|---|---|---|---|---|

| Type | Specification/mm | m/kg | Specification /mm | Inner diameter/mm | m/kg | m/kg | Working pressure Mpa |

| Straight seam steel pipe | Φ89*3 | 6.36 | Φ75*8 | 59 | 1.63 | 7.99 | 3.0 |

| Seamless steel pipe | Φ102*4 | 9.67 | Φ89*10 | 68 | 2.41 | 12.08 | 4.0 |

| Straight seam steel pipe | Φ140*3.5 | 11.79 | Φ130*10 | 110 | 3.66 | 15.45 | 3.0 |

| Straight seam steel pipe | Φ165*3 | 11.99 | Φ159*10 | 139 | 4.54 | 16.53 | 3.0 |

| Spiral steel pipe | Φ180*5 | 21.57 | Φ168*10 | 148 | 4.81 | 26.38 | 4.0 |

| Spiral steel pipe | Φ194*4 | 18.74 | Φ184*12 | 160 | 6.29 | 25.03 | 4.0 |

| Spiral steel pipe | Φ219*6 | 31.52 | Φ203*8 | 187 | 4.57 | 36.09 | 4.0 |

| Spiral steel pipe | Φ245*6 | 35.36 | Φ230*10 | 210 | 6.70 | 42.06 | 4.0 |

| Spiral steel pipe | Φ273*6 | 39.51 | Φ256*10 | 236 | 7.49 | 47.00 | 4.0 |

| Spiral steel pipe | Φ325*6 | 47.20 | Φ310*10 | 290 | 9.14 | 56.34 | 4.0 |

| Spiral steel pipe | Φ373*4 | 36.40 | Φ360*10 | 340 | 10.66 | 47.06 | 4.0 |

| Spiral steel pipe | Φ377*6 | 54.89 | Φ360*10 | 340 | 10.66 | 65.55 | 3.0 |

Custom sizes available, where moulds already exist from 20-1400mm OD, up to 65 WT. Product can be manufactured in any colour, and to all conformance requirements.

UHMWPE lined steel pipes are commonly used in industries such as mining, chemical processing, water treatment, and materials handling. They provide an effective solution for conveying abrasive, corrosive, and challenging fluids while maintaining the structural strength of the underlying steel pipe. The lining process involves bonding the UHMWPE material to the steel pipe through various methods, ensuring a secure and reliable lining that can withstand demanding operational conditions.

Lining steel pipes with UHMWPE offers several advantages for various industrial applications:

UHMWPE lined steel pipes are used to transport corrosive, abrasive, and challenging fluids in industries such as mining, chemical processing, water treatment, and materials handling. They provide excellent resistance to corrosion, abrasion, and chemical attack, making them suitable for applications where conventional steel pipes may degrade or require frequent maintenance.

The UHMWPE lining is typically applied through a bonding process, where the UHMWPE material is securely attached to the interior surface of the steel pipe. Various methods such as adhesive bonding, sintering, or mechanical interlocking are used to ensure a strong and durable bond between the lining and the pipe. This lining process ensures that the UHMWPE material remains intact even under challenging operating conditions.

Answer: UHMWPE lined steel pipes offer several advantages, including exceptional corrosion resistance, high abrasion resistance, smooth flow with reduced friction, and compatibility with a wide range of chemicals. They contribute to longer service life, lower maintenance costs, improved flow efficiency, and reduced downtime. UHMWPE lined steel pipes are particularly valuable in applications involving harsh environments or convey fluids that are abrasive, corrosive, or challenging to handle.

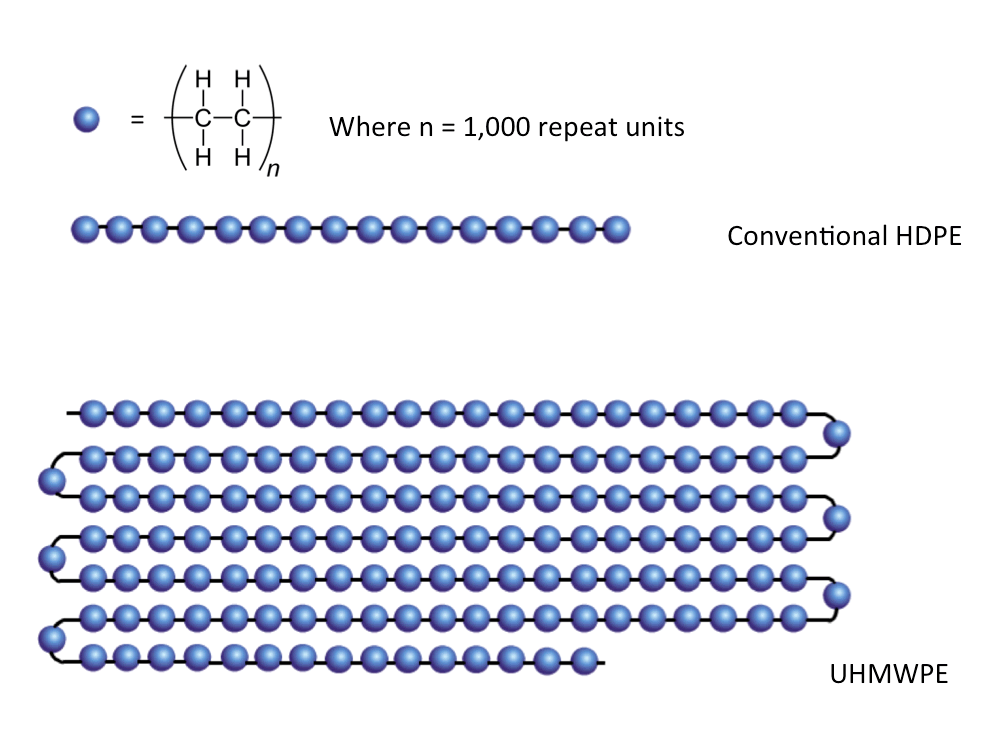

Ultra-High Molecular Weight Polyethylene (UHMWPE) is an engineering polymer that varies from high-density polyethylene (HDPE) in terms of average molecular weight and average chain length.

UHMWPE is highly resistant to chemicals, acids, and corrosive substances. Lining steel pipes with UHMWPE can help protect the pipe from internal corrosion caused by aggressive fluids or chemicals.

UHMWPE has excellent wear resistance, making it suitable for pipelines that transport abrasive materials such as slurries, ores, and industrial waste.

The smooth and low-friction surface of UHMWPE lining reduces the frictional resistance of fluids flowing through the pipe, thereby improving flow efficiency and reducing energy consumption.

UHMWPE is compatible with a wide range of chemicals and fluids, making it suitable for conveying various liquids in chemical, pharmaceutical, and processing industries.

The non-stick surface of UHMWPE lining prevents scaling and build-up of materials on the interior of the pipe, minimizing maintenance and cleaning requirements.

The durability of UHMWPE helps extend the overall service life of the lined steel pipe, reducing the need for frequent replacements.

UHMWPE is approved for use in food and beverage industries due to its non-toxic and non-contaminating properties.

UHMWPE lined steel pipe combinds advantages of both UHMWPE and steel which make it wear resistant, impact resistant, anti-corrosion, resistant to high pressure, self-lubricating, impact resistant.

The wear resistance is 4 to 7 times of Q235 steel pipe, 10 times of HDPE, it has the smallest friction coefficient in plastic ranks

5 times of ordinary PE pipes, 4 times than HDPE, 2 times of polycarbonate pipe, and 10 times of PTFE pipe

High self-lubrication and not adhesion, friction coefficient of only 0.006, the UHMWPE pipe can save energy of 20% under the same flow rate

Surface roughness of Ra0.00022, no dirt, no bacterium in long term service

The molecular weight of UHMWPE is more than 2 million, as saturated molecular structure, it has strong ability of aging under ultraviolet light, and mechanical properties is stable if not lower than -70℃

Small working face, low requirement of foundation, and with the performance of wear-resisting, corrosion resistance, frost resistance and anti-pollution, etc, after the operation, the pipe do not need to make daily maintenance, such as anti-rust and freeze-proofting, descaling, etc, and maintenance cost can be saved by more than 95%.

Odourless and high environment protection: it has smooth surface, will not be microbial adhesion in the ocean or sewage engineering, and ensure the stability of water quality

Ultra high molecular weight polyethylene is superior in comprehensive performance, abrasion resistance, low temperature, corrosion resistance, self lubrication, impact resistance in all plastic for the highest value, wear-resistant properties than PTFE, nylon, carbon steel and other materials, can be long-term in-169 to +80℃ conditions, known as "amazing" engineering plastics, Ultra-high molecular weight polyethylene Engineering Plastics (UHMW---PE) pipeline technology is becoming more and more mature in China, more and more projects adopt this kind of pipeline, become a kind of new thermoplastic engineering plastics with good price, it almost concentrates the advantages of various plastics, wear-resisting impact, self-lubricating, corrosion resistance, low temperature, hygienic non-toxic, Non-adhesion, water and other comprehensive properties, is an ideal pipe, can be widely used in mining (ore powder, pulp, tailings discharge pipelines) metallurgy, electricity, petroleum, textile, papermaking, food, chemical, mechanical, electrical and other industries.

UHMWPE denotes Ultra High Molecular Weight Polyethylene which is a polyethylene polymer with an average molecular weight is greater than 3,100,000 as defined by ASTM D4020 – Standard specification for UHMWPE polymers. This molecular weight is well above the molecular weight of most typical polymers which are between 1,000,000 and 400,000 thus earning the title Ultra-High Molecular Weight Polyethylene. Polyethylenes with molecular weight in the 3.1 -4.5 Million range have been found to exhibit the best combination of impact strength and abrasion resistance.

For Polyethylene molecular weight classification the following guidelines can be used:

A UHMWPE (Ultra-High Molecular Weight Polyethylene) lined steel pipe is a type of pipeline where the interior surface of the steel pipe is lined with a layer of UHMWPE material.

To cater to the requirements of long-distance transportation, high-pressure systems, exceptional wear resistance, and anti-adhesion properties, our company has undertaken the development and manufacturing of composite pipes ranging from DN63mm to DN630mm. Our UHMWPE pipes are capable of being combined with spiral welded pipes, high-quality seamless pipes, and other compatible materials. This innovative approach ensures the creation of pipes that are robust, versatile, and tailor-made to meet the diverse challenges posed by various industries.

A UHMWPE (Ultra High Molecular Weight Polyethylene) lined steel pipeline combines the durability of steel with the exceptional properties of UHMWPE to create a highly effective solution for conveying abrasive materials, corrosive fluids, and other challenging substances. In this pipeline design, a layer of UHMWPE is applied to the inner surface of the steel pipe, offering benefits such as superior abrasion resistance, chemical inertness, low friction, and reduced scaling or buildup. This combination provides an extended service life for the pipeline while maintaining a smooth flow and minimizing maintenance requirements. UHMWPE liner steel pipelines find applications in industries like mining, chemical processing, water treatment, and more, where the need for both strength and resistance to demanding environments is essential.

UHMWPE by virtue of its extremely high molecular weight yields several unique properties, including the highest abrasion resistance and highest impact strength of any plastic.

Ultra-high molecular weight polyethylene pipe (UHMWPE) wear-resistant plastic crown, is carbon steel, stainless steel 3-7 times.

Low friction coefficient, self-lubricating, anti-adhesion, no scaling, reduce the energy transmission of materials. Top of the plastic in the impact strength column. The impact energy absorption value is highest in all plastics and has a silencing nature. Good chemical stability. Excellent low-temperature resistance. Sanitation is non-toxic to food and drugs.

Ultrahigh molecular weight polyethylene (UHMWPE) shows unusually high wear resistance compared to most materials. This is due to a combination of very high molecular weight and the resulting entanglements and relative surface softness with a slippery waxy surface.

Because UHMWPE Pipe has a high molecular weight, it has good comprehensive properties and has become a new type of thermoplastic engineering plastic with excellent performance. It has almost the advantages of various plastics and has unparalleled wear resistance and resistance to ordinary polyethylene and other engineering plastics. Impact, self-lubrication, corrosion resistance, low-temperature resistance, hygienic non-toxic, non-adhesion, non-water absorption and other comprehensive properties. It has unique advantages in the transportation of solid particles, powder, slurry and gas.

At present, ultra-high molecular weight polyethylene pipes have achieved industrial continuous production in China. However, due to the characteristics of the UHMWPE raw materials, it is difficult to process UHMWPE pipes. Although the production of UHMWPE pipes has realized continuous extrusion production by a plastic extruder, its production speed is only ordinary plastics. The pipe production speed is 1%, so increasing the production rate of ultra-high molecular weight polyethylene pipes and improving the wear resistance index has become the focus of industry research.

Because the ultra-high molecular weight polyethylene pipe has excellent characteristics such as friction resistance, corrosion resistance, impact resistance, self-lubrication, non-adhesion, non-absorption of water, etc., it is recognized by the market, so the application range of ultra-high molecular weight polyethylene pipe is expanding.

The unique properties of the UHMWPE pipe material determine the slow speed of the pipe production line. The main equipment is the extruder and the mold.

As a Polyethylene UHMWPE Sheet Manufacturer, share with you the characteristics of UHMW-PE pipe products.

Ultra-high molecular weight polyethylene pipe refers to the pipe that is formed by using ultra-high molecular weight polyethylene as the main raw material. Its main characteristics are shown in the following points:

China's water supply and drainage pipelines mainly use PCCP pipes, cast iron pipes, and glass steel pipes. They are connected by sockets, sealed by rubber rings, and have serious leakage in the pipe network. The average leakage rate is about 15-30%, which wastes resources and increases pipe maintenance costs. The ultra-high molecular weight polyethylene pipe successfully solved this problem with excellent performance and brought major changes to the water supply and drainage engineering.

The ultra-high molecular weight polyethylene pipe has a roughness of 0.0065, the steel pipe has a roughness of 0.012, and the cement pipe has a roughness of 0.013. The water flow rate of ultra-high molecular weight polyethylene pipes of the same caliber is greater than that of PCCP pipes and cast-iron pipes. At the same flow rate, UHMWPE pipes can save energy by 25%.

Ultra-high molecular weight polyethylene pipe has a series of characteristics such as corrosion resistance, low-temperature resistance, non-scaling, and no leakage. Therefore, the pipe does not need to be rust-proof, decontaminated and overhauled for decades after operation, which can save more than 95% of operating and maintenance costs.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.