Cast basalt lined pipe, as a kind of wear-resistant and anti-corrosion material, when conveying materials with wear or corrosion properties, after 30 years of actual verification, cast basalt lined pipe can complete the task well.

Download PDF

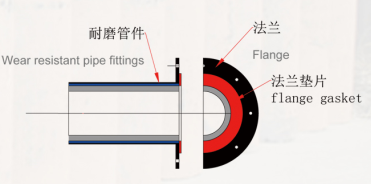

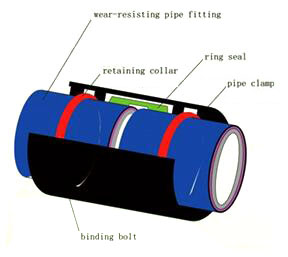

Cast blast lined pipe and fittings can connect with flange, quick assembly joints and welding.

Flange connection is one kind of common pipeline installation connections. By two pieces of flanges, pipeline, valve, equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority selection. Flanges have lots of different sizes. Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

The parameters of the outside steel pipe will be decided according to the working pressure of the system. The connection of the pipes and fitting will be of flange connections, easy—flexible joint connection or by welding.

By two pieces of flanges,pipeline,valve,equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority secection. Flanges have lots of differents sizes.

Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

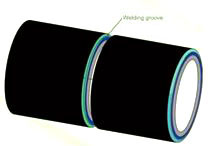

Beveled ends allow for proper alignment and penetration during welding, ensuring a strong and effective joint. This preparation is commonly used in various industries, especially in piping systems where welded connections are prevalent.

It suits short distance pipeline system without maintenance. It is one kind of common installation connections. It requires installation personnel higher welding ability. It also restricts by welding site, distance, welding positions. Welding connections is inconvenient in later maintenance.

It is one of high efficient and rapid installation connection. I t has the below characteristic: easily install and disassemble, fast installation, temperature adjustable compensation function, saving the necessary expansion in long pipeline. Easy-flexible joint also has angle compensation characteristic. At smaller angle turning points, easy-flexible joint can be instead of bends and adjust angle.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.