Straight Pipes With Ceramic Lining

Alumina Ceramic Lined Straight Pipes prevents the pipes from wear and erosion.

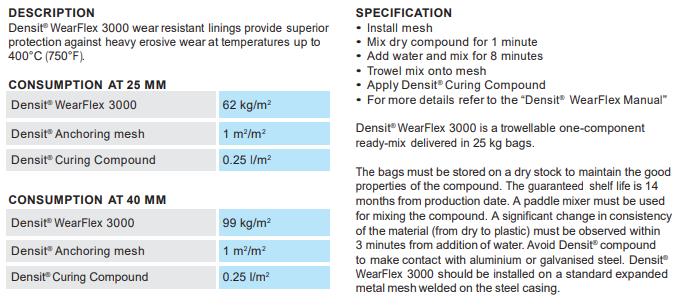

Densit® WearFlex 3000 is a trowellable, one-component, high strength, ready mix that provides superior protection against heavy erosive wear, catering for process temperatures up to 400°C (750°F).

Densit WearFlex 3000 can protect against severe erosive wear at temperatures up to 750°F (400°C). It's available in 25 kg bags and must be kept completely dry until use.

Examples of plant equipment and system components lined with Densit® WearFlex:

Grinding mills for clinker, cement, slag and coal; pneumatic conveyor systems for cement, slag and coal; dust extraction equipment; static and dynamic separators; cyclones; flash; chutes, etc.

To use Densit WearFlex 3000, you can:

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.