Pipe elbows

Pipe elbows are versatile pipe fittings used to make turns in piping systems, available in various angles and materials.

ASME 16.9 covers overall dimensions, tolerances, ratings, testing, and markings for factory-made wrought butt-welding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200).

Download PDFASME B16.9 also covers pipe fittings made to special dimensions, sizes, shapes, and tolerances by agreement between the manufacturer and the purchaser. Fabricated laterals, saddles, and other fittings employing circumferential or intersection welds are considered pipe fabrication other than ASME B16.9 fittings. However, fabricated lap joint stub ends are exempt from the above restrictions, provided they meet all the requirements of the applicable ASTM material specification.

The term “wrought” denotes fittings made of seamless or welded pipes, tubing, plates, or forgings. Metals-Piping supplies ASME B16.9 butt-welding pipe fittings in a comprehensive range of materials covering carbon steel, alloy steel, stainless steel and non-ferrous metals. These fittings include long radius elbows, reducing elbows, long radius returns, short radius elbows, short radius 180° returns, 3D elbows, straight tees, straight crosses, reducing tees, reducing crosses, lap joint stub ends, caps, concentric reducers, and eccentric reducers. All fittings supplied shall be free of imperfections such as dents, scratches, sharp intersections(corners), pits, and creases, etc.

ASME/ANSI B16.9 pipe end caps are designed to provide a secure seal at the end of a pipe. They are manufactured according to the ASME/ANSI B16.9 standard, which specifies the dimensions, tolerances, and markings for wrought steel butt-welding fittings, including end caps.

Pipe end caps are used in pipeline systems where a tight shut-off is required. They are ideal for applications where a secure seal is needed at the end of a pipe run, preventing ingress of contaminants and maintaining system pressure.

These end caps are typically made from forged steel to provide maximum strength. The forged construction offers superior strength compared to cast end caps, making them suitable for high-pressure drop services. They are designed to be welded to the end of a pipe, ensuring a strong and durable seal.

ASME/ANSI B16.9 pipe end caps are essential components in piping systems where an open end must be sealed. They are designed to be welded to the pipe, providing a secure and reliable seal.

ASME B16.9 Standard covers overall dimensions, tolerances,ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200).

Download PDF| Nominal | Outside Diameter | 90° Elbows | 45° Elbows | 180° Returns | ||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size |

Long Radius | Short Radius | Long Radius | Long Radius | ||||

| (inches) | (mm) | (inches) | Center to Face | Center to Face | Center to Face | Radius | Center to Center | Back to face |

| (inches) | (inches) | (inches) | (inches) | (inches) | (inches) | |||

| 1/2 | 21.3 | 0.84 | 1.5 | – | 5/8 | 2 | 1.875 | |

| 3/4 | 26.7 | 1.05 | 1.125 | – | 7/16 | 2.25 | 1.6875 | |

| 1 | 33.4 | 1.315 | 1.5 | 1 | 7/8 | 3 | 2.1875 | |

| 1.25 | 42.2 | 1.66 | 1.875 | 1.25 | 1 | 3.75 | 2.75 | |

| 1.5 | 48.3 | 1.9 | 2.25 | 1.5 | 1.125 | 3 | 4.5 | 3.25 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1.375 | 4 | 6 | 4.1875 |

| 2.5 | 73 | 2.875 | 3.75 | 2.5 | 1.75 | 5 | 7.5 | 5.1875 |

| 3 | 88.9 | 3.5 | 4.5 | 3 | 2 | 6 | 9 | 6.25 |

| 3.5 | 101.6 | 4 | 5.25 | 3.5 | 2.25 | 7 | 10.5 | 7.25 |

| 4 | 114.3 | 4.5 | 6 | 4 | 2.5 | 8 | 12 | 8.25 |

| 5 | 141.3 | 5.563 | 7.5 | 5 | 3.125 | 10 | 15 | 10.3125 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3.75 | 12 | 18 | 12.3125 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16.3125 |

| 10 | 273.1 | 10.75 | 15 | 10 | 6.25 | 15 | 30 | 20.375 |

| 12 | 323.9 | 12.75 | 18 | 12 | 7.5 | 18 | 36 | 24.375 |

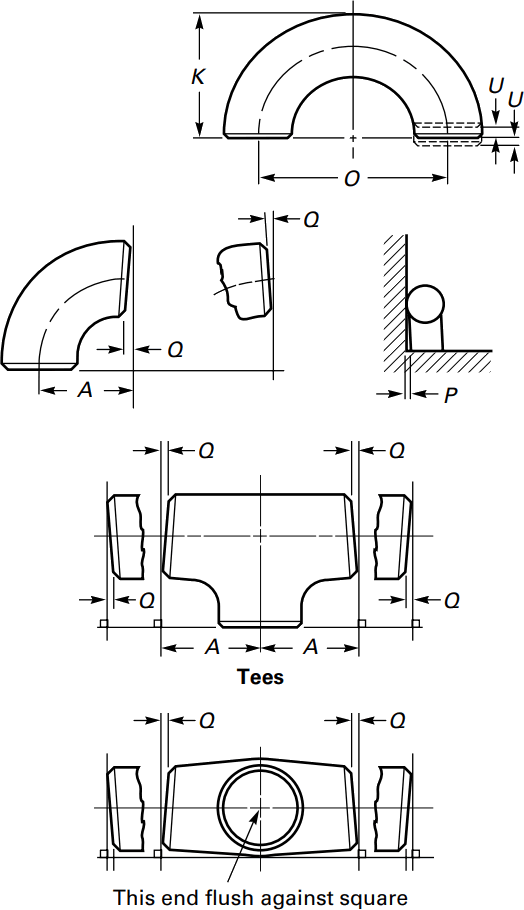

| NOMINAL PIPE SIZE NPS | ANGULARITY TOLERANCES | ANGULARITY TOLERANCES |

|---|---|---|

| Size | Off Angle Q | Off Plane P |

| ½ to 4 | 0.03 | 0.06 |

| 5 to 8 | 0.06 | 0.12 |

| 10 to 12 | 0.09 | 0.19 |

| 14 to 16 | 0.09 | 0.25 |

| 18 to 24 | 0.12 | 0.38 |

| 26 to 30 | 0.19 | 0.38 |

| 32 to 42 | 0.19 | 0.5 |

| 44 to 48 | 0.18 | 0.75 |

All dimensions are given in inches. Tolerances are equal plus and minus except as noted.

The ASME B16.9 pipe fittings can be used under the jurisdiction of the ASME Boiler & Pressure Vessel Code (BPVC) as well as the ASME Code for pressure piping. Referencing pressure ratings of flanges per ASME B16.5, they can be designated as Classes 150, 300, 600, 900, 1500 and 2500. The allowable pressure ratings for ASME B16.9 pipe fittings may be calculated as for straight seamless pipe of equivalent material in accordance with the rules established in the applicable sections of ASME B31 Code for pressure piping.

The design of butt welding pipe fittings made to ASME B16.9 shall be established by one of the following methods: (a) mathematical analyses contained in pressure vessel or piping codes; (b) proof testing; (c) experimental stress analysis with hydrostatic testing to validate experimental results; (d) detailed stress analysis with results evaluation.

Generally, ASME B16.9 pipe fittings shall be marked to show the following details: “trademark + material grade + wall thickness + size + heat number”. For example, “M ASTM A234 WP5 SCH80 6″ 385“. When steel stamps are used, care shall be taken so that

the marking is not deep enough or sharp enough to cause cracks or to reduce the wall thickness of the fitting below the minimum allowed.

The ASME B16.9 fittings may be made from an extensive range of mateirals covering (1) carbon and low-alloy steels in accordance with ASTM A234 and ASTM A420; (2) austenitic and duplex stainless steels in accordance with ASTM A403 and ASTM A815; (3) nickel alloys in accordance with ASTM B366; (4) aluminum alloys in accordance with ASTM B361; and (5) titanium alloys in accordance with ASTM B363.

Sizes 1/2″ – 48″

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.