Pipe elbows

Pipe elbows are versatile pipe fittings used to make turns in piping systems, available in various angles and materials.

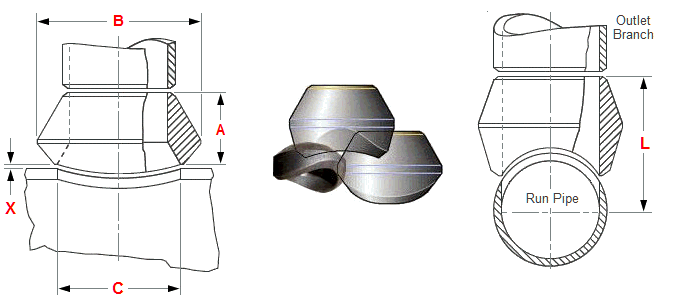

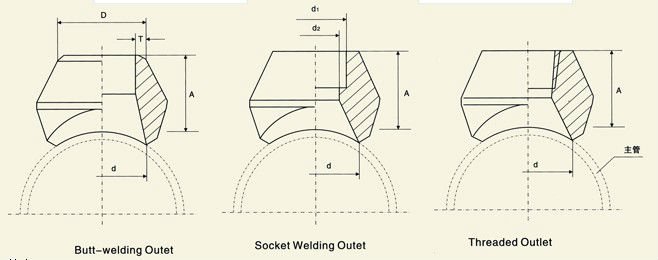

MSS SP-97 Integrally Reinforced Forged Branch Outlet Fittings — Socket Welding, Threaded, and Buttwelding Ends.

Download PDFThe MSS SP-97 standard defines the design, dimensions, materials, and pressure ratings for integrally reinforced branch outlet fittings, including weldolets, sockolets, and threadolets. These fittings provide branch connections on piping systems and are integral for creating safe and secure connections. By specifying reinforcement requirements, MSS SP-97 helps ensure that branch outlets can withstand the stresses of high-pressure environments without additional reinforcement.

The MSS SP-97 standard includes the following specifications:

The standard includes various types of branch outlet fittings, each with unique features:

MSS SP-97 fittings are widely used in high-pressure and high-temperature piping systems due to their strength and durability:

MSS SP-97 refers to the Standard Practice developed by the Manufacturers Standardization Society (MSS) for Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends. It provides specifications and guidelines for the design, materials, dimensions, testing, and marking of branch outlet fittings that are used to create branch connections on pipelines or vessels. These fittings are commonly used in various industries to facilitate branching off from main pipelines or equipment.

MSS SP-97 is a standard developed by the Manufacturers Standardization Society (MSS) of the Valve and Fittings Industry. It specifies requirements for weldolet, sockolet, threadolet, and nipple outlet fittings used for branch connections in piping systems.

The application of MSS SP-97 is to ensure the dimensional and material specifications for these types of outlet fittings are met, thus ensuring safe and reliable connections in piping systems. This standard is widely used in the oil and gas, petrochemical, and other industries where branch connections in pipelines are required.

The MSS SP-97 specification defines the requirements for integrally reinforced forged branch outlet fittings, including Weldolets, Sockolets, Threadolets, and Elbolets. It covers dimensions, materials, pressure ratings, and testing procedures for these fittings used in various industries like oil and gas, petrochemical, and power generation.

MSS(Manufacturers Standardization Society) is the only organization in the world dedicated exclusively to the technical needs of the valve and fittings industry.

The Manufacturers Standardization Society of the Valve and Fittings Industry (MSS) publishes international codes and standards to ensure interoperability, compliance and operation of process piping systems.

Standards and codes are written and revised by 25 technical committees and address topics such as valves, valve actuators, pipe fittings, flanges, and pipe hangers.

The MSS SP-97 Sockolet is one of the most frequently used branch connections, where the fitting is welded onto the outlet pipe. The ends of the MSS SP-97 Threadolet are designed with a bevel shape to ease this process. Therefore, a Weldolet is categorized as a butt-weld fitting.

MSS SP-97 Weldolet is a specific type of branch connection fitting as defined by the Manufacturers Standardization Society (MSS). It falls under the category of Integrally Reinforced Forged Branch Outlet Fittings. Weldolets are designed to provide a branch connection from a larger pipe to a smaller pipe or vessel. They are typically used in piping systems where a smaller diameter branch line is required to be connected to a larger diameter main pipe.

Weldolets have a welding outlet that allows for a smooth and strong connection to the main pipe through a welding process. This type of fitting reduces the need for additional fabrication work and offers a more efficient way to create branch connections compared to traditional methods. MSS SP-97 provides specifications for the design, materials, dimensions, testing, and markings of Weldolets and other similar branch connection fittings.

Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends.

Fittings manufactured to this Standard Practice are designed to make a fully reinforced branch connection in accordance with applicable piping code requirements, when attached, at an opening in a run pipe by means of a full penetration weld.

This classification refers to its beveled outlet that is butt-welded to the branch pipe during installation. The weldolet is ideal for replacing a tee on 90-degree branches with a reinforced connection that protects the branch pipe by reducing stress concentration due to its shape and size.

| pressure | NPS | A | B | C | D |

|---|---|---|---|---|---|

| STD | 1/2″ | 19.05 | 34.93 | 23.81 | 15.88 |

| STD | 3/4″ | 22.23 | 41.28 | 30.16 | 20.64 |

| STD | 1″ | 26.99 | 50.8 | 36.51 | 26.19 |

| STD | 1 1/4″ | 31.75 | 60.3 | 44.45 | 34.93 |

| STD | 1 1/2″ | 33.34 | 73 | 50.8 | 41.28 |

| STD | 2″ | 38.1 | 88.9 | 65.09 | 52.39 |

| STD | 2 1/2″ | 41.28 | 103.19 | 76.2 | 61.91 |

| STD | 3″ | 44.45 | 122.24 | 93.66 | 77.79 |

| STD | 3 1/2″ | 50.8 | 136.53 | 98.43 | 90.49 |

| STD | 4″ | 50.8 | 152.4 | 120.65 | 101.6 |

| STD | 5″ | 57.15 | 180.98 | 141.29 | 128.59 |

| STD | 6″ | 60.3 | 215.9 | 169.86 | 153.99 |

| STD | 8″ | 69.85 | 263.53 | 220.66 | 201.61 |

| STD | 10″ | 77.79 | 319.09 | 274.64 | 254 |

| STD | 12″ | 85.73 | 377.83 | 325.44 | 304.8 |

| STD | 14″ | 88.9 | 409.58 | 357.19 | 336.55 |

| STD | 16″ | 93.66 | 463.55 | 407.99 | 387.35 |

| STD | 18″ | 103.19 | 527.05 | 473.08 | 438.15 |

| STD | 20″ | 117.48 | 585.79 | 509.59 | 488.95 |

| STD | 24″ | 136.53 | 708.03 | 638.18 | 590.55 |

| XS | 1/2″ | 19.05 | 34.93 | 23.81 | 15.88 |

| XS | 3/4″ | 22.23 | 41.28 | 30.16 | 20.64 |

| XS | 1″ | 26.99 | 50.8 | 36.51 | 26.19 |

| XS | 1 1/4″ | 31.75 | 61.91 | 44.45 | 34.93 |

| XS | 1 1/2″ | 33.34 | 73 | 50.8 | 41.28 |

| XS | 2″ | 38.1 | 88.9 | 65.09 | 52.39 |

| XS | 2 1/2″ | 41.28 | 103.19 | 76.2 | 61.91 |

| XS | 3″ | 44.45 | 122.24 | 93.66 | 77.79 |

| XS | 3 1/2″ | 50.8 | 136.53 | 98.43 | 90.49 |

| XS | 4″ | 50.8 | 152.4 | 120.65 | 101.6 |

| XS | 5″ | 57.15 | 180.98 | 141.29 | 128.59 |

| XS | 6″ | 77.79 | 225.43 | 169.86 | 153.99 |

| XS | 8″ | 98.43 | 269.88 | 220.66 | 193.68 |

| XS | 10″ | 88.9 | 327.03 | 265.11 | 254 |

| XS | 12″ | 100.01 | 385.76 | 330.2 | 304.8 |

| XS | 14″ | 104.78 | 423.86 | 363.54 | 330.2 |

| XS | 16″ | 112.71 | 479.43 | 419.1 | 381 |

| XS | 18″ | 119.06 | 536.58 | 473.08 | 431.8 |

| XS | 20″ | 127 | 593.73 | 528.64 | 482.6 |

| XS | 24″ | 139.7 | 708.03 | 638.18 | 584.2 |

Fittings may be made to special dimensions, size, shape, tolerances, or of other wrought material by agreement between the manufacturer and the purchaser.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.