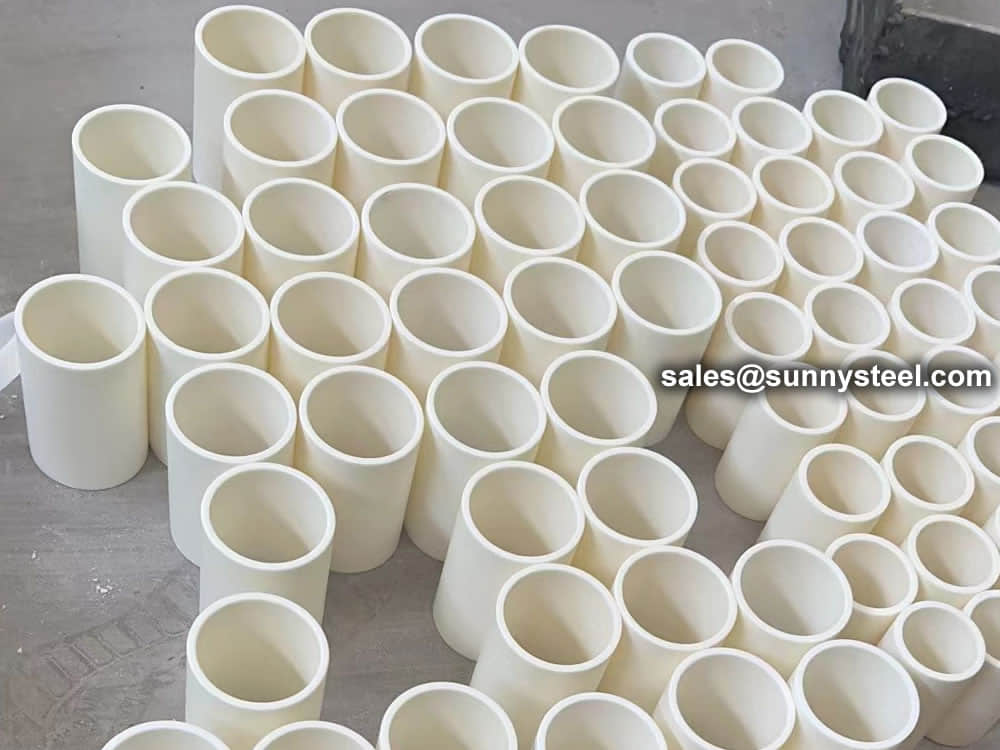

A 99% Al₂O₃ (alumina) ceramic sleeve is a high-purity ceramic component renowned for its exceptional properties, making it suitable for various industrial applications.

Download PDF

Alumina ceramic is known for its excellent wear resistance, high-temperature resistance, and corrosion resistance, making it suitable for various industrial applications.

Corrosion alumina tube material has excellent chemical stability under high temperature, it is not easy to oxidize, and Corrosion alumina tube has good corrosion resistance to acid, alkali and salt.

Aluminum(Al2O3) ceramic products are widely used because of it’s good wear resistance, such as power plant, mine, coal transportation, etc.

It has much longer lifespan than traditional steel pipe, which can help to reduce production cost greatly.

Sunny Steel can produce all kinds of alumina ceramic tube, elbow, ring, three way tube and cone, etc.

High Hardness and Wear Resistance: With a Rockwell hardness of ≥90 HRA, these sleeves offer excellent resistance to abrasion, ensuring durability in demanding environments.

High-Temperature Stability: Capable of operating at temperatures up to 1650°C, they maintain structural integrity under extreme heat.

Corrosion Resistance: Alumina ceramics exhibit excellent resistance to chemical aggression, making them ideal for corrosive environments.

Electrical Insulation: They possess superior dielectric properties, suitable for electrical and electronic applications.

| Material | Unit | 95% Al2O3 |

|---|---|---|

| Purity | % | 95 |

| Color | --- | White/Pink |

| Density | g/cm3 | 3.65 |

| Water Absorption | % | 0 |

| Moh's Hardness | --- | 9 |

| HV Hardness | --- | >1300 |

| Flexural Strength @25℃ | Mpa | 300 |

| Fracture Toughness | Mpa.M1/2 | 3~4 |

| Compressive Strength (25℃) | Mpa | 2200 |

| Thermal Conductivity @25℃ | W/M.K | 18-22 |

| Thermal Expansion Coefficient (25-1000℃) |

10-6mm/℃ | 8 |

| Thermal Shock Resistance | △T(℃) | 220 |

| Max. Working Temperature | ℃ | 1500 |

| Dielectric Strength | Kv/Mm | 16 |

| Electrical Resistivity (@25℃) | Ω.Cm | 1014 |

| Dielectric Constant (@1MHz, 25℃) | --- | 9 |

| Dielectric Loss (Tan Delta) (@1MHz, 25℃) |

--- | 0.0004 |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.