Wear resistant lined bends and pipes are commonly used in pneumatic conveying systems to minimize wear and extend the lifespan of the components.

Download PDFWear resistant lined bends and pipes for pneumatic conveying are designed to withstand high levels of abrasion caused by the movement of materials.

Wear resistant lined bends and pipes for pneumatic conveying are designed to withstand high levels of abrasion caused by the movement of materials such as granules, powders, and slurries through pneumatic conveyor systems. These pipelines experience high levels of wear which can cause damage over time and result in costly maintenance and downtime.

To combat this issue, abrasion-resistant linings are applied to the inner surface of the pipe or bend, which reduces the amount of wear and tear. The abrasion-resistant lining can be made from various materials such as rubber, ceramic, polyurethane or a blend of these materials.

Features of wear resistant lined bends and pipes:

In summary, wear resistant lined bends and pipes for pneumatic conveying are an excellent solution for protecting pipelines from abrasion and wear caused by the movement of abrasive materials. They provide cost-effective, long-lasting, and versatile solutions for many industries that need to transport abrasive materials.

Frequently a pneumatic conveying system is used to convey materials with high abrasiveness, that is, with a marked tendency to consume by friction to the wall of the tubing where they flow.

For example foundry sand, clinker, ash from boiler combustion, quartz.

The phenomenon of wear in the tubes is due in part to the conveying speed and the consequent friction of the product in the pipes. But the main cause is the changing direction, which is why the wear of major concern takes place in conveying bends, due to the increased friction.

That is why the bends of a pneumatic conveying line are manufactured with the bending radius the widest possible and in any case with strong limitations with respect to the smallest value adoptable. And, in the case of heavy abrasion, wear resistant internal coatings are used.

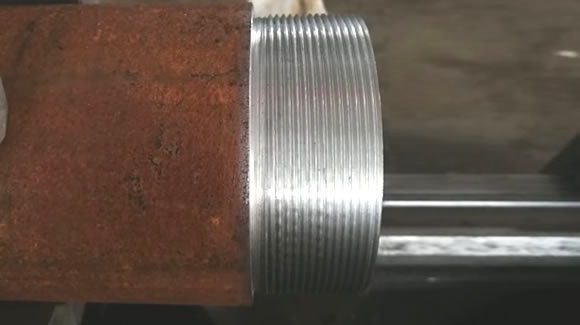

The manufacture is an essential factor for the effectiveness of the abrasion resistant components, for example the perfect alignment of the inner sectors of lining that allows a longer life of the component as well as the selection of a chemical composition that involves adequate hardness.

We propose wear resistant lined bends with thicknesses adequate for heavy duty, coupled with straight sections of suitable length, to take account of the angle of incidence with which the particles collide with the surface and the lingering effects of turbulence of the flow after the change of direction. We also design and manufacture special components of various shapes, “T”, “Y”, “S”, with sizes and lengths also on design.

Wear resistant lined bends and pipes are commonly used in pneumatic conveying systems to minimize wear and extend the lifespan of the components. Here's a summary of the information found in the search results:

Wear resistant lined bends and pipes are versatile and can be used in various industries, including mining, cement, power generation, and more. They are specifically designed for use in pneumatic conveying systems, where wear often occurs in pipe bend walls.

These bends and pipes are often coated or lined with wear-resistant materials such as basalt or ceramics Basalt coatings offer a high degree of Mohs hardness, typically at least 8 Ceramic linings provide high hardness, wear resistance, and corrosion resistance.

The use of wear resistant lined bends and pipes helps reduce wear and abrasion in pneumatic conveying lines, minimizing product attrition and extending the lifespan of the components. They can also improve the reliability and availability of the pneumatic conveying system.

Bends in pneumatic conveying systems can be broadly classified into common-radius bends (including elbows, short-radius, long-radius, and long-sweep bends), common fittings (such as tee bends and mitered bends), and specialized bends with innovative designs. Lined bends, such as ceramic lined bends, are a type of specialized bend that offers wear resistance.

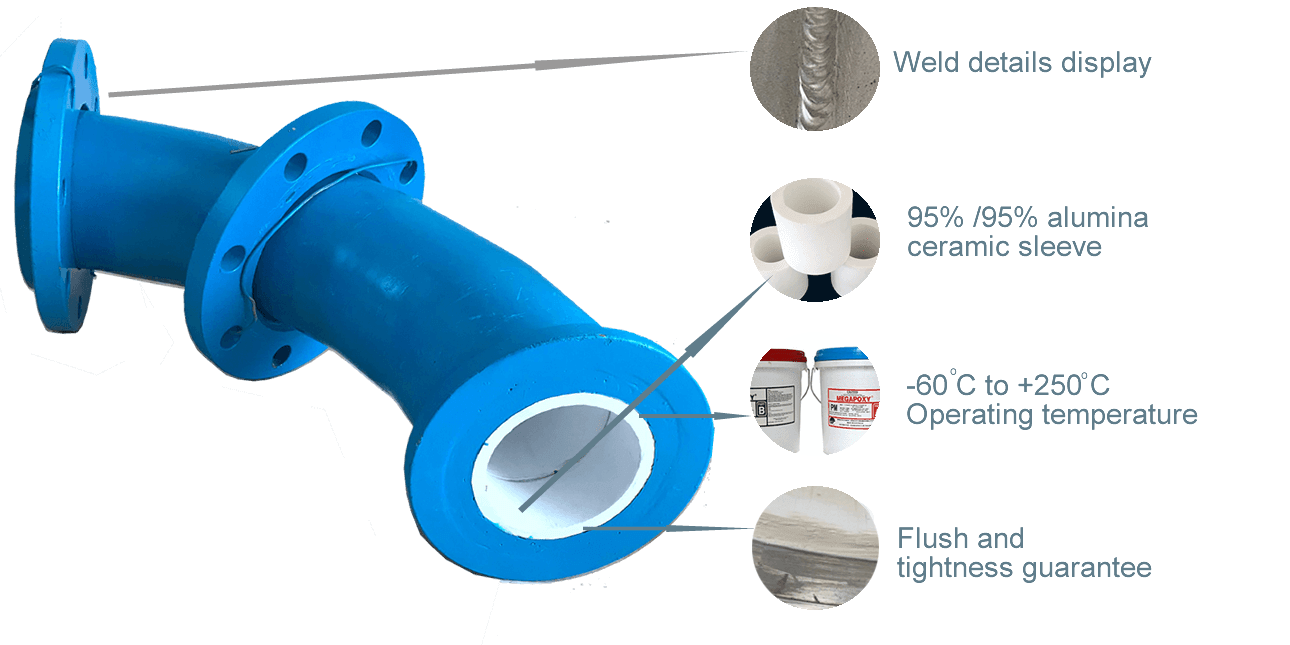

The main raw material of wear resistant ceramic ring is a special kind of ceramic with AL2O3 as the and the rare metal oxide as the flux, which is melted by high temperature at 1700 °C. The Ceramic Sleeves Lined Pipe as a whole part, and then assemble it into the steel pipe with our high-strength-temperature-resistant epoxy adhesive.

Recently 95% alumina ceramic sleeve lined pipes, elbows and T pipes have been largely applied in lithium battery material conveying system. The big diameter ceramic sleeve is always a big problem for the ceramic tube manufacturers since it’s very difficult to control the deformation rate of the ceramic sleeve after it’s sintering .Also It will also need an advanced and big isostatic pressing machine to do this .So it will not only express the company’s production capability ,but company’s technology. Right now, our factory have owned both advantages which are wear resistant ceramic pressing facilities and technologies.

| Items | 92% | 95% |

|---|---|---|

| Al2O3 | ≥92% | ≥95% |

| SiO2 | 0.0451 | 0.028 |

| Fe2O3 | 0.0001 | 0.0001 |

| TiO2 | 0.0005 | / |

| CaO | 0.018 | 0.0045 |

| MgO | 0.011 | 0.0051 |

| K2O | 0.0004 | 0.0003 |

| Na2O | 0.0031 | 0.0063 |

| Volume Density | 3.62 g/cm3 | 3.65 g/cm3 |

| Water Absorption (%) | ≤0.02% | ≤0.02% |

| POROSITY | ≤1 | ≤1 |

| Hardness | 9 Mohs | 9 Mohs |

| Flexural strength | ≥2000 Mpa | ≥2250 Mpa |

| Abrasion | ≤0.02 | ≤0.02 |

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features as an abrasion resistant, heat resistant and corrosion resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

| Data | Metric | Imperial |

|---|---|---|

| Tensile Strength, Ultimate | 655 MPa | 95 ksi |

| Tensile Strength, Yield | 290 MPa | 42 ksi |

| Elongation at Break (in 2") | 0.55 | 0.55 |

| Rockwell Hardness | B84 | B84 |

304 Stainless Steel Plate has very good formability and can be readily welded by all common methods.

Ceramic sleeve lined pipes are commonly used in industries such as mining, power generation, cement, steel, and chemical processing. They are particularly effective in applications where materials with high abrasiveness or corrosiveness need to be transported.

Abrasion resistant pipe using steel skeleton packaging, and the two ends of the pipe with plastic head, to prevent dust and rain into the pipeline inside, to ensure the beauty of the product.

For different production environments, our company has developed a wear-resistant pipe for a variety of media, based on the temperature, wear and corrosion requirements of the field media, and for the initial application of the scene, our company to provide wear-resistant ceramic ring for the Lined composite straight pipe design to meet the on-site wear resistance, heat resistance and corrosion resistance requirements, in view of this program for the new design (formerly ceramic chip technology, there are many gaps, easy to wear).

After the ceramic ring in the pipe is installed and the thread is processed, the dirt outside the pipe is cleaned, and the outer surface of the pipe is treated with three layers of anticorrosive paint to meet the export requirements.

| Item | Data | Characteristics of binder |

|---|---|---|

| Density (g/cm3) | 1.32 | We use the Australian Megapoxy high strength structural adhesive, this structural glue is modified epoxy resin polymer, anti-aging ability, and wear-resistant ceramic bonding to form a strong and cushion of the anti-wear layer, cured water, anti-corrosion performance is excellent, toughness, displacement-resistant effect is remarkable.

|

| Compressive strength (MPa) | 40 | |

| Shear Strength MPa | 26 | |

| Impact toughness Kj/m2 | 10 | |

| Hardness HB | 9.5 | |

| Elastic Modulus GPa | 2.2 | |

| Expansion coefficient 10-6/℃ | 20.1 | |

| Softening temperature℃ | 263 | |

| Coking temperature℃ | 335 | |

| Acid resistance(24H) | Stability | Test solution : 15%H2SO4 |

| Alkali resistance(24H) | Stability | Test solution: NaOH |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.