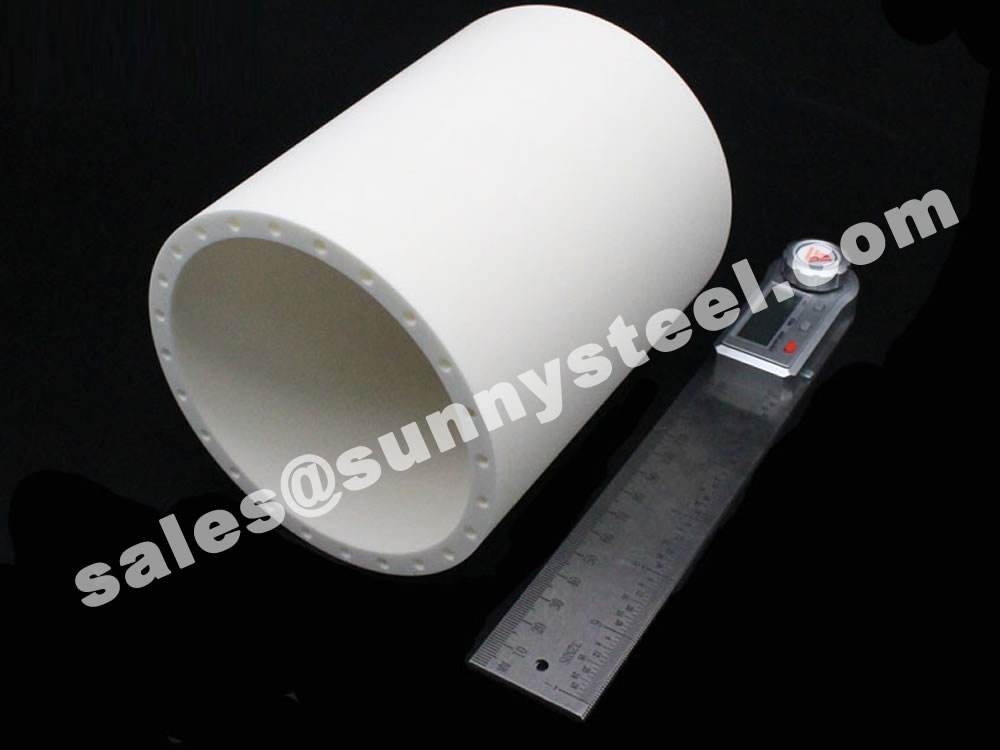

Ceramic pipe sleeve is a cylindrical covering made of ceramic material that is used to protect pipes from corrosion, wear, and chemical attack.

Download PDFThe main raw material of wear resistant ceramic ring is a special kind of ceramic with AL2O3 as the and the rare metal oxide as the flux, which is melted by high temperature at 1700 °C. The Ceramic Sleeves Lined Pipe as a whole part, and then assemble it into the steel pipe with our high-strength-temperature-resistant epoxy adhesive.

The ceramic pipe sleeve is an inner lining made from ceramic materials such as alumina or silicon carbide. Ceramics are chosen for their exceptional resistance to wear, corrosion, and abrasion. The ceramic sleeve acts as a protective layer inside the pipe, safeguarding it from deterioration when exposed to harsh materials.

Ceramic pipe sleeves are commonly used in industries like mining, mineral processing, power generation, and others that involve the transport of abrasive materials like ores, chemicals, or slurries. They extend the lifespan of pipes and reduce maintenance needs, making them a cost-effective solution for handling challenging materials.

According to customer requirements, we can provide different high-purity alumina ceramic tubes, such as: Alumina ceramic(Al2O3):95%;96%;97%;98%;99%;99.5%:99.7%;99.9%…etc.

We are proud to say that our facility has a wide selection of alumina ceramic tubes, which are a standard protection part. Our vast, readily-available inventory means we can supply our customers' ceramic tube needs immediately, even for hard-to-find or specialty products. Alumina is used in a variety of general-purpose applications, and their grade is chosen based on the application environment. What's more, we can formulate different purity alumina in our factory if needed for more demanding applications.

| Material | Unit | 95% Al2O3 | 96% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | 99.8% Al2O3 |

|---|---|---|---|---|---|---|

| Purity | % | 95 | 96 | 99 | 99.5 | 99.8 |

| Color | --- | White/Pink | White | Ivory | Ivory | Ivory |

| Density | g/cm3 | 3.65 | 3.72 | 3.85 | 3.90 | 3.92 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0 |

| Moh's Hardness | --- | 9 | 9 | 9 | 9 | 9 |

| HV Hardness | --- | >1300 | >1300 | 1700 | 1750 | 1800 |

| Flexural Strength @25℃ | Mpa | 300 | 300 | 330 | 375 | 390 |

| Fracture Toughness | Mpa.M1/2 | 3~4 | 3~4 | 3~4 | 4 | 4 |

| Compressive Strength (25℃) | Mpa | 2200 | 2200 | 2350 | 2450 | 2500 |

| Thermal Conductivity @25℃ | W/M.K | 18-22 | ≥24 | 27 | 29 | 32 |

| Thermal Expansion Coefficient (25-1000℃) |

10-6mm/℃ | 8 | 8 | 8 | 8 | 8 |

| Thermal Shock Resistance | △T(℃) | 220 | 220 | 180-200 | 180-200 | 180-200 |

| Max. Working Temperature | ℃ | 1500 | 1500 | 1700 | 1750 | 1750 |

| Dielectric Strength | Kv/Mm | 16 | 17.2 | 20 | 22 | 22 |

| Electrical Resistivity (@25℃) | Ω.Cm | 1014 | 1014 | 1014 | 1014 | 1014 |

| Dielectric Constant (@1MHz, 25℃) | --- | 9 | 9 | 9.7 | 9.7 | 9.8 |

| Dielectric Loss (Tan Delta) (@1MHz, 25℃) |

--- | 0.0004 | 0.0002 | 0.0002 | 0.0001 | 0.0001 |

| Parameter | Details |

|---|---|

| Material options | Alumina ( purity from 40% to 99.8%), Zirconia, Silicon carbide, Silicon nitride |

| Forming methods | Extrusion, Dry pressed, Hot pressed, Ceramic Injection Molding, ISO pressed |

| Dimensional capability | The inner diameter can be min.1mm, the outer diameter can max.800mm |

| Dimensional tolerance | The OD to be 0.005mm, the ID to be 0.01mm, the length to be 0.001mm |

| Surface treatment | External and internal surface to be polished, glazed or metalized |

| Secondary processing | CNC machining, lapping, threaded, drilling, grinding, precision laser cutting |

Alumina ceramic is the most widely applied technical ceramics which has high hardness and mechanical strength, good wear resistance, high temperature resistance, good electrical insulation and good resistance to corrosion etc. We could make custom manufacturing for alumina ceramic parts in required size and shapes.

Alumina ceramic, also known as Al2O3 ceramic or aluminium oxide ceramic, is an incredibly versatile technical ceramic material that is used in all kinds of industries. It offers so many benefits, including being highly strong, with excellent dielectric properties, and exceptional wear and corrosion resistance, as well as remarkable heat resistance. Alumina ceramic is one of the hardest and most wear-resistant materials on the planet, and it is so tough that diamond tools are required to machine it after sintering. Its incredible versatility allows it to be used in a wide range of industries, from machinery and electrical and electronics to semiconductors, petroleum, chemicals, textiles, and more.

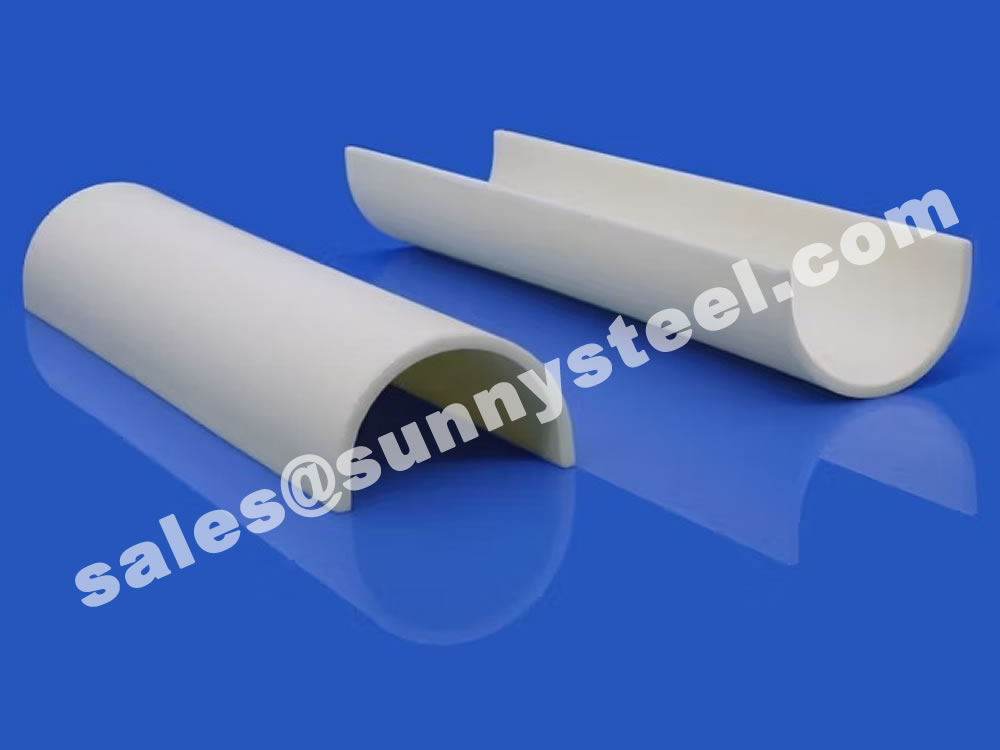

It is a common solution for extending the life of pipelines in harsh environments such as chemical plants, oil refineries, and waste treatment facilities. The ceramic material used in pipe sleeves has excellent resistance to high temperatures, abrasion, and chemical aggression, which makes it an ideal material for protection against corrosion and erosion. The ceramic pipe sleeves come in various sizes and shapes to fit different pipe dimensions and are typically installed by sliding them over the pipe’s outer surface.

Recently 95% alumina ceramic pipe sleeve has been largely applied in lithium battery material conveying system.

The main raw material of wear resistant ceramic sleeve is a special kind of ceramic with AL2O3 as the and the rare metal oxide as the flux, which is melted by high temperature at 1700 °C. The big diameter ceramic sleeve is always a big problem for the ceramic tube manufacturers since it’s very difficult to control the deformation rate of the ceramic sleeve after it’s sintering. Also It will also need an advanced and big isostatic pressing machine to do this. So it will not only express the company’s production capability, but company’s technology. Right now, our factory have owned both advantages which are wear resistant ceramic pressing facilities and technologies.

In addition, the flatness of ceramic casing is also an important factor affecting the size of lithium battery materials.We did a lot of analysis and improved our manufacturing techniques to solve both of these problems.Now it can help lithium battery delivery systems better solve these problems, with better material purity, longer service life and better economic benefits.

For The Convenience Of Customers, Are To Provide A More Specific Process Is As Follows:

95% alumina ceramic sleeve lined pipes, elbows and T pipes have been largely applied in lithium battery material conveying system in recently years.

The wear resistant ceramic ring is a special kind of ceramic with Al2O3 as the main raw material and the rare metal oxide as the flux, which is melted by high temperature at 1700 oC.

Ceramic sleeve lined pipe has a continuous ceramic liner covering the inner surface of the pipe. The ceramic liner, or sleeve, is typically made of high-quality alumina ceramics, which provides excellent resistance to wear, abrasion and corrosion.

Ceramic sleeve lined pipes are commonly used in industrial applications where the pipeline is exposed to harsh conditions, such as in mining, power generation, oil and gas, and chemical processing. The ceramic sleeve provides superior wear resistance and protects the underlying steel pipe from premature failure due to abrasion or corrosion.

In addition to their excellent wear properties, ceramic sleeve lined pipes may also provide benefits such as improved flow rates, lower maintenance costs, and longer service life. They may also be used in applications where hygiene is important, as the ceramic sleeve lining is non-toxic and does not react with most chemicals.

Ceramic sleeve lined pipes may be manufactured in various sizes and shapes, including elbows, tees, and reducers, to meet the specific requirements of each application. The ceramic sleeve may be bonded to the steel pipe using specialized adhesives and may be installed using conventional welding or mechanical joining techniques.

While ceramic sleeve lined pipes can offer significant benefits in terms of wear resistance and longevity, they are typically more expensive than traditional steel pipes due to the cost of the ceramic liner and specialized manufacturing processes.

Ceramic pipe sleeves are a type of ceramic lining designed to protect metal, plastic or composite piping systems from wear and abrasion caused by high-velocity flows of abrasive materials. They are typically made of highly engineered ceramic materials such as alumina or silicon carbide, which provide excellent resistance to wear, corrosion, and erosion.

Ceramic pipe sleeves are widely used in industries such as mining, power generation, and chemical processing where the harsh environment can cause significant wear and damage to the piping systems.

The advantages of using ceramic pipe sleeves include:

Overall, ceramic pipe sleeves are an effective and reliable solution for protecting piping systems from the harsh effects of abrasive materials. They offer superior wear resistance, corrosion resistance, and improved efficiency compared to traditional materials, reducing maintenance costs and improving system performance.

Grinding is the first process used for ceramic materials. Ceramic grinding refers to the surface processing of ceramics with abrasives after forming or sintering. The method is to select a large grain grinding wheel or an electroplated diamond grinding wheel on the existing grinding machine for conventional grinding.

However, ceramics have the characteristics of high hardness and strong wear resistance, so different processing technologies are needed to treat different product requirements. Different processing methods can be used when processing outer circles, inner holes, planes, and threads. Generally, the minimum tolerance can reach ±0.01mm.

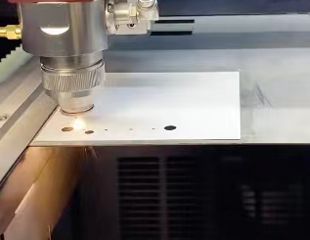

Laser processing ceramic technology uses a high-energy density laser beam to act on the surface of ceramic materials to make them melt under heat, thus realizing the processing of ceramic materials. It is mainly used to process ceramic parts or ceramic material surfaces with complex shapes and small dimensions.

Laser processing has various advantages, such as fast processing speed, timeliness, and high accuracy. The machining accuracy is high and can reach the micron level.

However, the equipment is complex and requires experienced operators. This demands higher qualifications for operators. Our company is equipped with experienced operators who can process various ceramic parts according to customer requirements. Laser cutting, laser drilling, laser scribing, and other processes can be completed.

Grinding and polishing is an ultra-precision machining method. This method uses free abrasives to produce fine screening effects on the surface material to be processed, achieving the processing effect. In the ultra-precision machining and finishing of ceramic materials, especially in the precision machining of ceramic balls for ceramic bearings, grinding and polishing play an irreplaceable role.

To further improve the surface accuracy after ceramic polishing, soft elastic or viscoelastic tools and micro-powder abrasives are used to make the surface of the workpiece reach a mirror-like finish. The mechanism of polishing is mechanical micro-removal: the micro-cutting action of the front end of the abrasive removes the concave and convex surfaces. Through grinding and polishing, the product can achieve a mirror effect.

Our company is equipped with special laser marking equipment, which can carve special words or logos according to customer needs. If the customer has other requirements, it can also be made according to the customer's requirements.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.