Butt Weld Pipe Fittings

Precision engineered butt weld fittings for seamless pipe connections.

Designed for versatility, our high-torque couplings ensure seamless performance in various applications.

Introducing our innovative product, the flexible coupling—a key player in the world of industrial solutions. Widely used in pipeline connections for conveying various media, it serves as a new type of flexible pipe joint, replacing traditional flanges and compensators. This innovative solution enhances adaptability and efficiency in diverse applications.

Flexible couplings play a crucial role in industrial settings, addressing alignment issues. They are widely used in pipeline connections for conveying various media, providing a flexible pipe joint that replaces flanges and compensators. Explore the diversity of our product to meet the needs of different industries.

Besides being used as an important pipe fitting, couplings are also used in the following:

Pipe couplings are primarily used to join two or more sections of pipes together. They provide a secure and leak-proof connection, ensuring the continuity of fluid or gas flow in the piping system.

Couplings are often used for pipe repair and maintenance. They allow for the quick and easy replacement of damaged or corroded sections of pipe without the need for extensive cutting or welding.

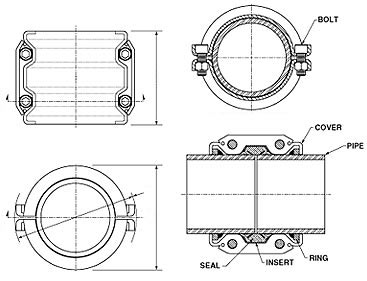

Parts of Pipe Coupling

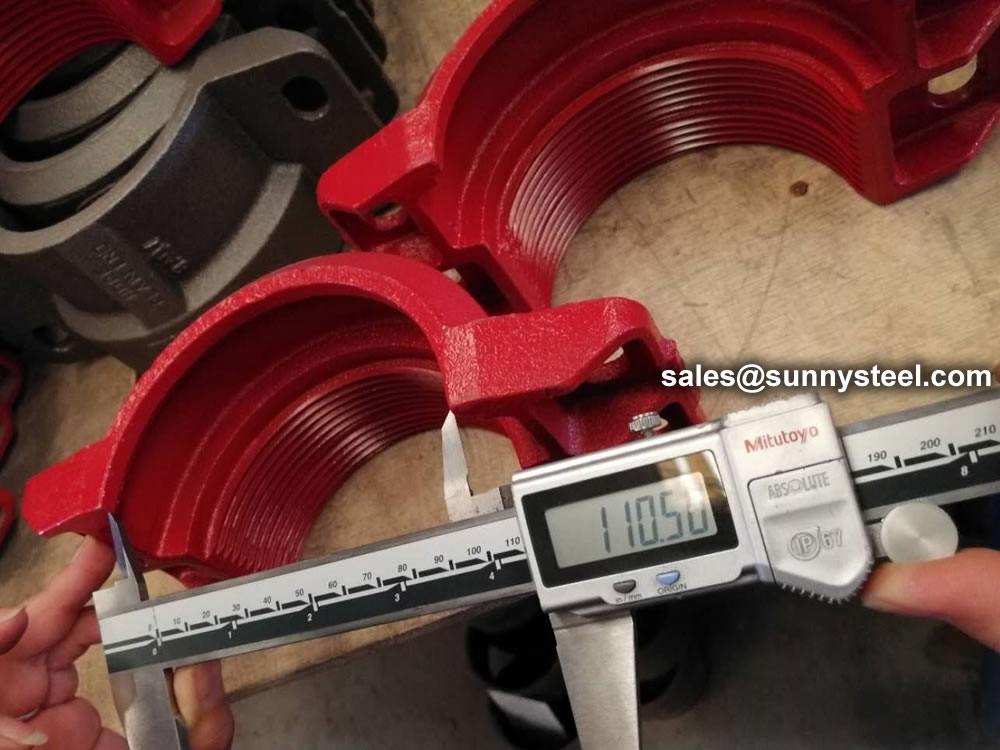

Some important features of couplings are as follows:

Pipe couplings are made of various materials and the buyers should always consider the material used for making them. Some of the materials used for making couplings are:

Any type of packing is available according to customer need to worldwide destinations.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.