Coupling Fittings

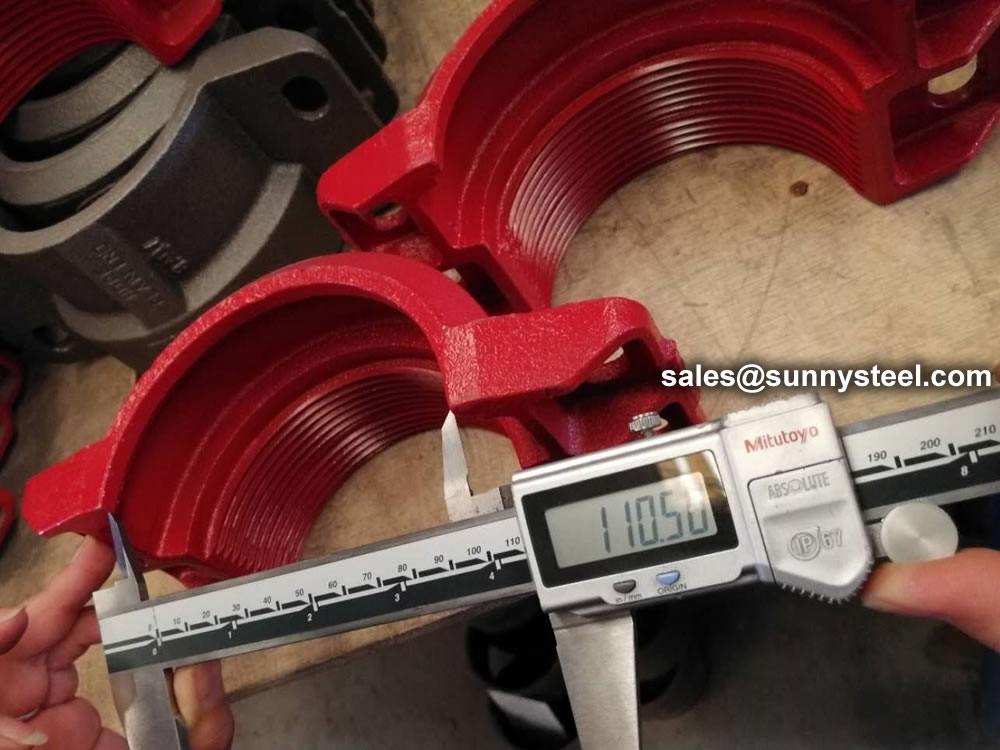

High-quality coupling fittings for secure pipe connections.

A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power.

A coupling is a mechanical device used to connect two shafts together at their ends for the purpose of transmitting power. Couplings are essential in various industrial and mechanical systems to ensure that power can be transmitted efficiently and reliably from one component to another. There are several types of couplings, each designed for specific applications and conditions.

Pipe couplings are highly demanded in the pipe fitting market. Pipe couplings are fittings that help to extend or terminate pipe runs. These fittings are also used to change pipe size. Couplings extend a run by joining two lengths of pipe. They are known as reduced coupling if they are used to connect pipes of different sizes.

Couplings are critical in ensuring the longevity and efficiency of mechanical systems. They are often chosen based on the specific needs of the application, such as the amount of torque that needs to be transmitted, the level of flexibility required, and the operating conditions.

Couplings are also known as repair couplings. These couplings are without stops or ridges and they can be fixed anywhere along the pipe length for preventing leak of any kind.

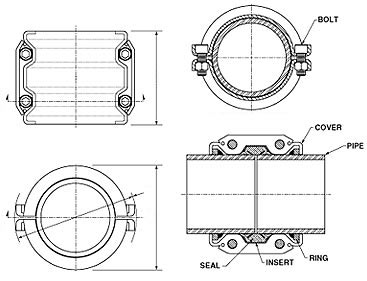

Parts of Pipe Coupling

Some important features of couplings are as follows:

Pipe couplings are made of various materials and the buyers should always consider the material used for making them. Some of the materials used for making couplings are:

Besides being used as an important pipe fitting, couplings are also used in the following:

Pipe couplings are primarily used to join two or more sections of pipes together. They provide a secure and leak-proof connection, ensuring the continuity of fluid or gas flow in the piping system.

Couplings are often used for pipe repair and maintenance. They allow for the quick and easy replacement of damaged or corroded sections of pipe without the need for extensive cutting or welding.

Any type of packing is available according to customer need to worldwide destinations.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.