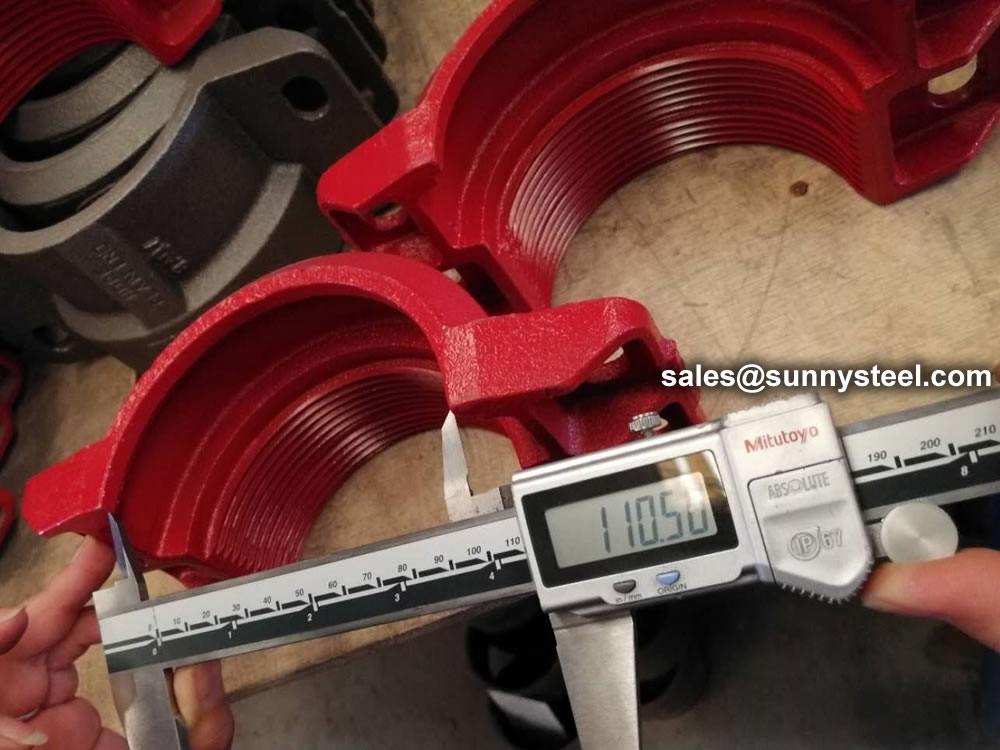

Coupling Fittings

High-quality coupling fittings for secure pipe connections.

The ring type pipe joint is used for the connection between pipes.

Tubing coupling mainly aims to solve the existing couplings easily generated due to fatigue fracture stress concentration problems.

Krh and krj series forging clamp type flexible pipe joints can effectively compensate the thermal expansion and cold contraction of the pipeline system due to temperature change, and compensate the angle change caused by the sinking of the pipeline foundation. They are resistant to high pressure, easy to install, and the comprehensive cost performance is much better than that of flange connection.

| Nominal Pressure (MPa) | Nominal Diameter (DN Mm) | Maximum Clearance At Pipe End (△ Mm) | Maximum Angle (Θ°) | Tube Deflection (F Mm/M) | L₁ | L | D | D₁ | D₂ | B | B₁ | Bolt | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameter (D) | Quantity | ||||||||||||

| Mm | Mm | Pc. | |||||||||||

| 4 | 150 | 10 | 2.74 | 47 | 307 | 259 | 226 | 154 | 168 | 68 | 120-130 | 16 | 2 |

| 175 | 10 | 2.35 | 41 | 333 | 285 | 252 | 178 | 194 | 68 | 120-130 | |||

| 200 | 10 | 1.48 | 26 | 358 | 310 | 277 | 207 | 219 | 68 | 120-130 | |||

| 225 | 10 | 1.33 | 23 | 384 | 336 | 303 | 232 | 245 | 68 | 120-130 | |||

| 250 | 10 | 1.20 | 21 | 412 | 364 | 331 | 259 | 273 | 68 | 120-130 | |||

| 300 | 10 | 1.04 | 18 | 483 | 427 | 383 | 310 | 325 | 68 | 120-130 | 18 | ||

| 350 | 10 | 1.03 | 18 | 535 | 479 | 435 | 359 | 377 | 68 | 120-130 | |||

| 400 | 10 | 0.97 | 16 | 595 | 535 | 484 | 408 | 426 | 68 | 120-130 | 20 | ||

| 2.5 | 450 | 10 | 0.93 | 16 | 649 | 589 | 538 | 462 | 480 | 68 | 120-130 | ||

| 500 | 10 | 0.90 | 15 | 703 | 641 | 588 | 512 | 530 | 68 | 120-130 | 22 | ||

| 600 | 10 | 0.88 | 15 | 803 | 741 | 688 | 610 | 630 | 68 | 120-130 | |||

| 1.6 | 700 | 10 | 0.82 | 14 | 889 | 829 | 778 | 700 | 720 | 68 | 120-130 | 20 | 4 |

| 800 | 10 | 0.80 | 14 | 989 | 929 | 878 | 800 | 820 | 68 | 120-130 | |||

| 900 | 10 | 0.73 | 12 | 1093 | 1031 | 978 | 900 | 920 | 68 | 120-130 | 22 | ||

| 1000 | 10 | 0.70 | 12 | 1193 | 1131 | 1078 | 1000 | 1020 | 68 | 120-130 | |||

Any type of packing is available according to customer need to worldwide destinations.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.