Pipe elbows

Pipe elbows are versatile pipe fittings used to make turns in piping systems, available in various angles and materials.

A Weldolet is a type of pipe fitting used for branch connections on pipes.

It is designed to fit over the run pipe and be welded onto it, with a branch pipe connected to the other end. This creates a strong and permanent connection between the pipes, making it an efficient and durable solution for piping systems.

A Weldolet is the most common type of branch connection, typically welded onto the outlet pipe. The ends are beveled to facilitate the welding process, classifying the Weldolet as a butt-weld fitting. Weldolets are crafted to reduce stress concentrations and offer integral reinforcement.

Branch connection fittings encompass more than just tees and laterals; they also include Weldolets. Weldolets are welded branch connections designed to match or surpass the schedule of the pipe used. Each is labeled with an outlet size and the pipe sizes it can be welded to. For instance, if marked as 5-3×3/4", it has an outlet size of 3/4" and fits pipe sizes 3", 3 1/2", 4", 5", with a maximum gap of 1/32" for the largest size. Regardless of your pipe size, there is an Olet available for the job. Olets with a size of 4 inches or smaller are designed to fit various pipe sizes, while those with a size of 5 inches and larger are designed for specific pipe sizes. A flat base is available for connecting to pipe caps and vessel heads.

A Weldolet creates a 90° branch connection and is available in full size or reducing options for a straight section of pipe. The designation of a Weldolet is based on the run length and the branch length. For instance, a 6-inch Weldolet on a 10-inch pipe would be labeled as a 10x6 Weldolet. Weldolets are engineered to minimize stress concentrations and provide integral reinforcement without the need for additional weld reinforcement.

Weldolet is olet pipe fittings that can supply an outlet from a larger pipe to a smaller pipe in piping & tubing systems. The Weldolet Forged Pipe Fittings are the most common type of olet branch connection fittings which is ideal for high pressure and high-temperature applications. ASME B16.11 Weldolet can easily be installed on run pipe and welded with buttweld techniques.

Weldolet Buttweld Pipe Fittings expedite installation and demand less space. We produce these branch connection pipe fittings, known as olets, in various material grades such as Stainless Steel, Carbon Steel, Alloy Steel, Nickel Alloy, and more. Weldolet pipe fittings find significant utility in lengthy connection pipe fittings within various industries.

Weldolet installation involves the following key steps:

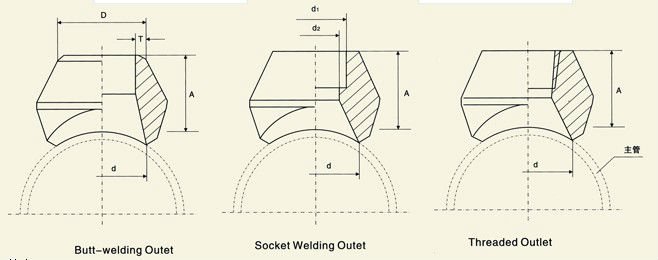

Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends.

Fittings manufactured to this Standard Practice are designed to make a fully reinforced branch connection in accordance with applicable piping code requirements, when attached, at an opening in a run pipe by means of a full penetration weld.

This classification refers to its beveled outlet that is butt-welded to the branch pipe during installation. The weldolet is ideal for replacing a tee on 90-degree branches with a reinforced connection that protects the branch pipe by reducing stress concentration due to its shape and size.

| pressure | NPS | A | B | C | D |

|---|---|---|---|---|---|

| STD | 1/2″ | 19.05 | 34.93 | 23.81 | 15.88 |

| STD | 3/4″ | 22.23 | 41.28 | 30.16 | 20.64 |

| STD | 1″ | 26.99 | 50.8 | 36.51 | 26.19 |

| STD | 1 1/4″ | 31.75 | 60.3 | 44.45 | 34.93 |

| STD | 1 1/2″ | 33.34 | 73 | 50.8 | 41.28 |

| STD | 2″ | 38.1 | 88.9 | 65.09 | 52.39 |

| STD | 2 1/2″ | 41.28 | 103.19 | 76.2 | 61.91 |

| STD | 3″ | 44.45 | 122.24 | 93.66 | 77.79 |

| STD | 3 1/2″ | 50.8 | 136.53 | 98.43 | 90.49 |

| STD | 4″ | 50.8 | 152.4 | 120.65 | 101.6 |

| STD | 5″ | 57.15 | 180.98 | 141.29 | 128.59 |

| STD | 6″ | 60.3 | 215.9 | 169.86 | 153.99 |

| STD | 8″ | 69.85 | 263.53 | 220.66 | 201.61 |

| STD | 10″ | 77.79 | 319.09 | 274.64 | 254 |

| STD | 12″ | 85.73 | 377.83 | 325.44 | 304.8 |

| STD | 14″ | 88.9 | 409.58 | 357.19 | 336.55 |

| STD | 16″ | 93.66 | 463.55 | 407.99 | 387.35 |

| STD | 18″ | 103.19 | 527.05 | 473.08 | 438.15 |

| STD | 20″ | 117.48 | 585.79 | 509.59 | 488.95 |

| STD | 24″ | 136.53 | 708.03 | 638.18 | 590.55 |

| XS | 1/2″ | 19.05 | 34.93 | 23.81 | 15.88 |

| XS | 3/4″ | 22.23 | 41.28 | 30.16 | 20.64 |

| XS | 1″ | 26.99 | 50.8 | 36.51 | 26.19 |

| XS | 1 1/4″ | 31.75 | 61.91 | 44.45 | 34.93 |

| XS | 1 1/2″ | 33.34 | 73 | 50.8 | 41.28 |

| XS | 2″ | 38.1 | 88.9 | 65.09 | 52.39 |

| XS | 2 1/2″ | 41.28 | 103.19 | 76.2 | 61.91 |

| XS | 3″ | 44.45 | 122.24 | 93.66 | 77.79 |

| XS | 3 1/2″ | 50.8 | 136.53 | 98.43 | 90.49 |

| XS | 4″ | 50.8 | 152.4 | 120.65 | 101.6 |

| XS | 5″ | 57.15 | 180.98 | 141.29 | 128.59 |

| XS | 6″ | 77.79 | 225.43 | 169.86 | 153.99 |

| XS | 8″ | 98.43 | 269.88 | 220.66 | 193.68 |

| XS | 10″ | 88.9 | 327.03 | 265.11 | 254 |

| XS | 12″ | 100.01 | 385.76 | 330.2 | 304.8 |

| XS | 14″ | 104.78 | 423.86 | 363.54 | 330.2 |

| XS | 16″ | 112.71 | 479.43 | 419.1 | 381 |

| XS | 18″ | 119.06 | 536.58 | 473.08 | 431.8 |

| XS | 20″ | 127 | 593.73 | 528.64 | 482.6 |

| XS | 24″ | 139.7 | 708.03 | 638.18 | 584.2 |

Fittings may be made to special dimensions, size, shape, tolerances, or of other wrought material by agreement between the manufacturer and the purchaser.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.