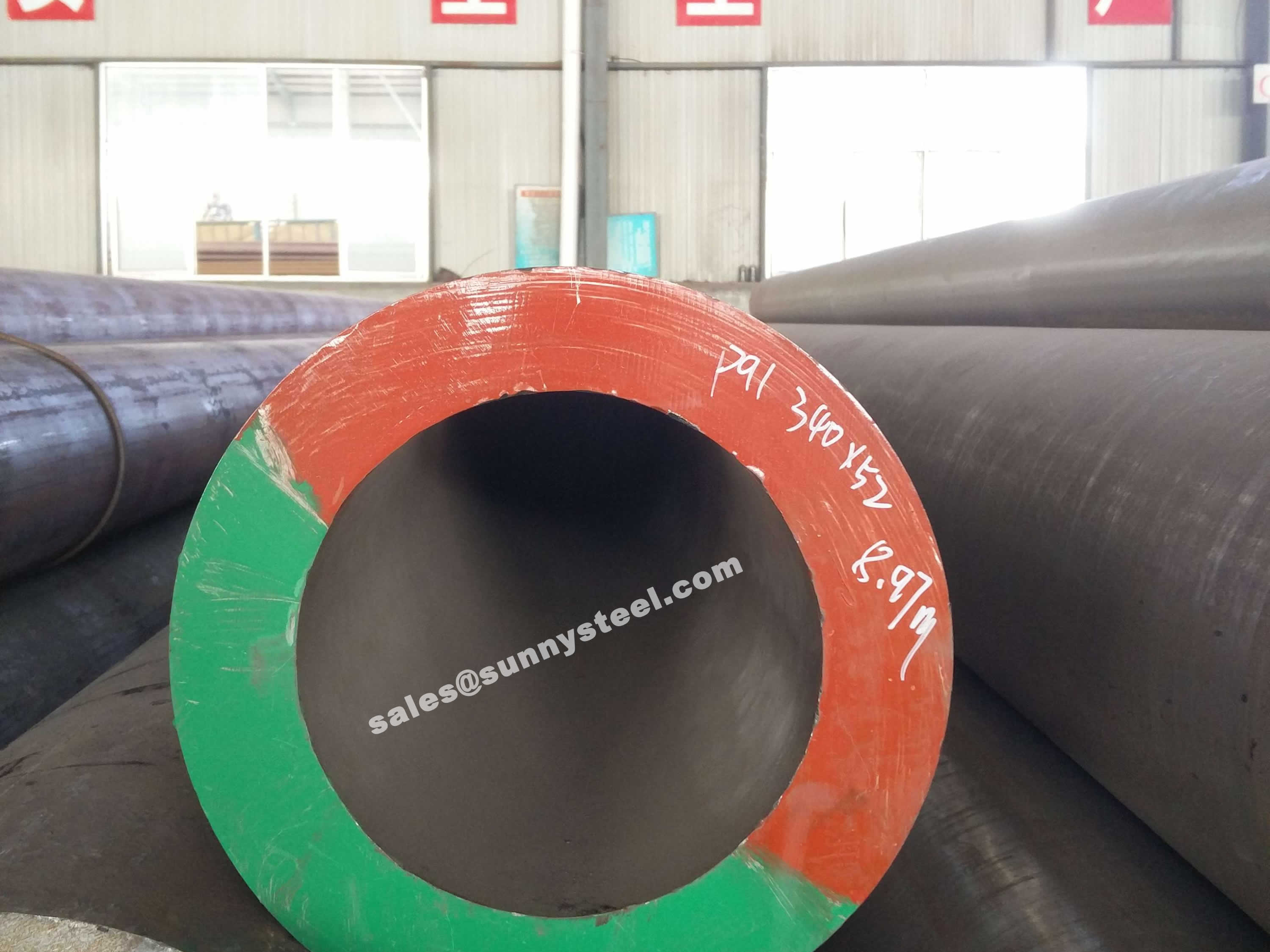

ASTM A335 P91

ASTM A335 P91 alloy pipe, known for its high creep strength and resistance to high-temperature exposure.

ASTM A335/A335M Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service.

Download PDFThis specification covers seamless ferritic alloy-steel pipe for high-temperature service. The pipe shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Grade P2 and P12 steel pipes shall be made by coarse-grain melting practice. The steel material shall conform to chemical composition, tensile property, and hardness requirements. Each length of pipe shall be subjected to the hydrostatic test. Also, each pipe shall be examined by a non-destructive examination method in accordance to the required practices. The range of pipe sizes that may be examined by each method shall be subjected to the limitations in the scope of the respective practices. The different mechanical test requirements for pipes, namely, transverse or longitudinal tension test, flattening test, and hardness or bend test are presented.

ASTM A335 is a standard specification for seamless ferritic alloy-steel pipe intended for high-temperature service.

This material is commonly used in power plants, refineries, and other industrial settings where high-temperature and high-pressure conditions are encountered. The "A" in ASTM A335 stands for "alloy," indicating that the pipe is made from alloy steel, which typically includes elements such as chromium, molybdenum, and sometimes vanadium to enhance its high-temperature properties.

1 This specification covers nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for high-temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Selection will depend upon design, service conditions, mechanical properties, and high-temperature characteristics.

2 Several grades of ferritic steels (see Note 1) are covered. Their compositions are given in Table 1.

Note 1.. Ferritic steels in this specification are defined as low- and intermediate-alloy steels containing up to and including 10% chromium.

3 Supplementary requirements (S1 to S7) of an optional nature are provided. These supplementary requirements call for additional tests to be made, and when desired, shall be so stated in the order together with the number of such tests required.

4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation of this specification is specified in the order.

Note The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as "nominal diameter", "size", and "nominal size".

ASTM A335 Seamless Steel Pipe is generally named chrome moly pipe for the chemical elements- Molybdenum and Chromium. Molybdenum improves steel performances as steel strength, elastic limit, wear resistance, impact and hardenability.

ASTM A335 seamless steel pipe is a popular choice for high-temperature applications due to several key reasons:

In summary, ASTM A335 seamless steel pipe is popular in high-temperature applications due to its high-temperature resistance, corrosion resistance, high strength, good weldability, uniform properties, and cost-effectiveness. Its combination of properties makes it an ideal choice for use in various high-temperature and high-pressure applications, especially in the power generation, chemical processing, and oil and gas industries.

ASTM Specification pipe confirming to ASTM A335 shall have the following chemical properties. Tensile and Hardness Requirements The tensile properties of the ASTM A335 pipe shall conform to the requirements as prescribed. Pipe of Grades P91, P92, and P122 shall have a hardness not exceeding 250 HB/265 HV [25 HRC]. For pipe of Grades P91, P92, P122, and P911, Brinell, Vickers, or Rockwell hardness tests shall be made on a specimen from each lot (see Note 7). These pipe bear high resistance to rupture at high temperature and pressures. With hydrogen crack resistance and sulfide stress corrosion cracking chrome moly pipe are highly preferred over Carbon pipe.

| Grade | C | Mn | P max | S max | Si | Cr | Mo | V | N | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| P1 | 0.1-0.2 | 0.3-0.8 | 0.025 | 0.025 | 0.1-0.5 | 1.0-1.5 | 0.44-0.65 | / | / | / |

| P2 | 0.1-0.2 | 0.3-0.61 | 0.025 | 0.025 | 0.1-0.3 | 0.5-0.81 | 0.44-0.65 | / | / | / |

| P5 | ≤0.15 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 4.0-6.0 | 0.45-0.65 | / | / | / |

| P5b | ≤0.15 | 0.3-0.6 | 0.025 | 0.025 | 1.0-2.0 | 4.0-6.0 | 0.45-0.65 | / | / | / |

| P5c | ≤0.12 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 4.0-6.0 | 0.45-0.65 | / | / | / |

| P9 | ≤0.15 | 0.3-0.6 | 0.025 | 0.025 | 0.25-1.0 | 8.0-10.0 | 0.9-1.1 | / | / | / |

| P11 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | 0.5-1.0 | 1.0-1.5 | 0.44-0.65 | / | / | / |

| P12 | 0.05-0.15 | 0.3-0.61 | 0.025 | 0.025 | ≤0.5 | 0.8-1.25 | 0.44-0.65 | / | / | / |

| P15 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | 1.15-1.65 | / | 0.44-0.65 | / | / | / |

| P21 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 2.65-3.35 | 0.8-1.06 | / | / | / |

| P22 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 1.9-2.6 | 0.87-1.13 | / | / | / |

| P23 | 0.04-0.1 | 0.1-0.6 | 0.03 | 0.01 | ≤0.5 | 1.9-2.6 | 0.05-0.3 | 0.2-0.3 | ≤0.015 | Cb(0.02-0.08) ,B(0.001-0.006) |

| Al(≤0.03), W(1.45-1.75) | ||||||||||

| Ni(≤0.4), Ti(0.005-0.060) | ||||||||||

| P24 | 0.05-0.1 | 0.3-0.7 | 0.02 | 0.01 | 0.15-0.45 | 2.2-2.6 | 0.9-1.1 | 0.2-0.3 | ≤0.012 | Ti(0.06-0.1), Al(≤0.02) |

| B(0.0015-0.007) | ||||||||||

| P36 | 0.1-0.17 | 0.8-1.2 | 0.03 | 0.025 | 0.25-0.50 | ≤0.30 | 0.25-0.50 | ≤0.02 | ≤0.02 | Ni(1.0-1.3), Cu(0.5-0.8) |

| Cb(0.015-0.045), Al(≤0.050) | ||||||||||

| P91 | 0.08-0.12 | 0.3-0.6 | 0.02 | 0.01 | 0.2-0.5 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.03-0.07 | Ni(≤0.4), Al(≤0.02), Cb(0.06-0.1) |

| Ti(≤0.01), Zr(≤0.01) | ||||||||||

| P92 | 0.07-0.13 | 0.3-0.6 | 0.02 | 0.01 | ≤0.50 | 8.5-9.5 | 0.3-0.6 | 0.15-0.25 | 0.03-0.07 | Ni(≤0.4), AL(≤0.02), Cb(0.04-0.09) |

| W(1.5-2.0), B(0.001-0.006) | ||||||||||

| Ti(≤0.01), Zr(≤0.01) | ||||||||||

| P122 | 0.07-0.14 | ≤0.7 | 0.02 | 0.01 | ≤0.50 | 10.0-11.5 | 0.25-0.6 | 0.15-0.3 | 0.04-0.1 | Ni(≤0.5), Al(≤0.02), Ti(≤0.01) |

| W(1.5-2.5), Cu(0.3-1.7), Zr(≤0.01) | ||||||||||

| Cb(0.04-0.1), B(0.0005-0.005) | ||||||||||

| P911 | 0.09-0.13 | 0.3-0.6 | 0.02 | 0.01 | 0.1-0.5 | 8.5-9.5 | 0.9-1.1 | 0.18-0.25 | 0.04-0.09 | Ni(≤0.4), Cb(0.06-0.1) |

| B(0.0003-0.006),Al(≤0.02) | ||||||||||

| W(0.9-1.1),Ti(≤0.01),Zr(≤0.01) |

ASTM A335 pipe may be either hot finished or cold drawn with the finishing treatment as required in Grade P2 and P12 – The steel shall be made by coarse- grain melting practice. Specific limits, if any, on grain size or deoxidation practice shall be a matter of agreement between the manufacturer and purchaser.

| Werkstoff /DIN | EN | ASTM |

|---|---|---|

| 1.5415 | 16Mo3 | A335 Grade P1 |

| 1.7335 | 13CrMo4-5 | A335 Grade P11, P12 |

| 1.738 | 10CrMo9-10 | A335 Grade P22 |

| 1.7362 | X11CrMo5 | A335 Grade P5 |

| A335 Grade P9 | ||

| 1.4903 | X10CrMoVNb9-1 | A335 Grade P91 |

| Tensile Strength, min., psi | P-5 | P-9 | P-11 | P-22 | P-91 |

|---|---|---|---|---|---|

| ksi | 60 | 60 | 60 | 60 | 85 |

| MPa | 415 | 415 | 415 | 415 | 585 |

| Yield Strength, min., psi | |||||

| ksi | 30 | 30 | 30 | 30 | 60 |

| MPa | 205 | 205 | 205 | 205 | 415 |

Product Analysis At the request of the purchaser, an analysis of two pipe from each lot shall be made by the manufacturer. A lot of ASTM A335 pipe shall consist of the following: NPS Designator Under 2 400 or fraction thereof 2 to 5 200 or fraction thereof 6 and over 100 or fraction thereof. Note: ASTM A335 P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC].

| Grade | Tensile strength | Yield strength |

|---|---|---|

| P1,P2 | 380 | 205 |

| P12 | 415 | 220 |

| P23 | 510 | 400 |

| P91 | 585 | 415 |

| P92,P11 | 620 | 440 |

| P122 | 620 | 400 |

It also enhances the corrosion resistance of steel, and inhibits pitting. Chromium (or chrome) is the essential constituent of stainless steel. Any steel with 12% or more Chrome is considered stainless. Chrome is virtually irreplaceable in resisting oxidation at elevated temperatures. Chrome raises the tensile, yield, and hardness at room temperatures. The composition chrome moly alloy steel pipe make it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

| Grade | Heat Treatment Type P5, P9, P11, and P22 |

Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

|---|---|---|---|

| A335 P5 (b,c) | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 – 1375 [715 - 745] | |

| A335 P9 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| A335 P11 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1200 [650] | |

| A335 P22 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| A335 P91 | Normalize and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Quench and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.