SSIC Thermocouple Protection Tube

Designed to protect thermocouples from extreme temperatures and abrasion.

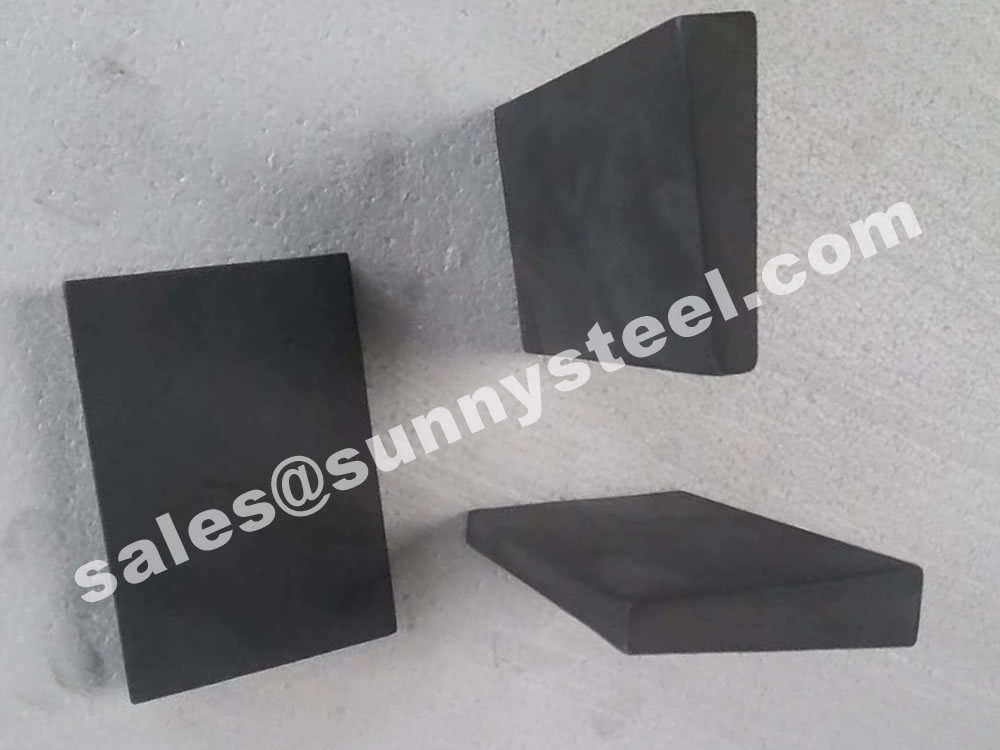

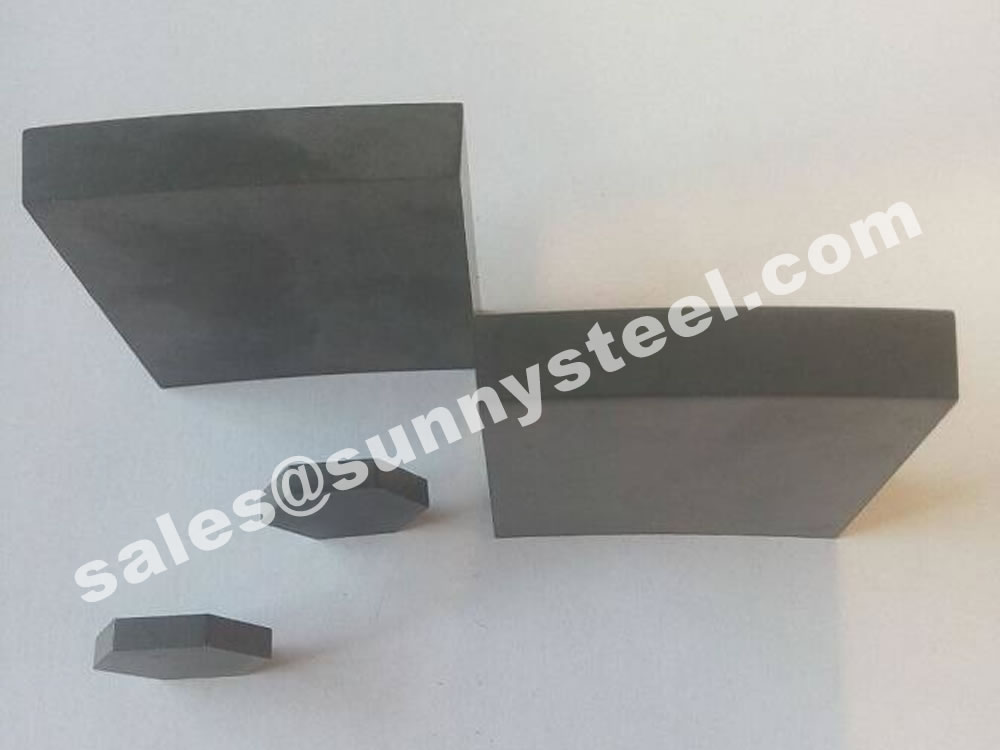

SISIC Batt (Silicon Infiltrated Silicon Carbide) is a high-performance material known for its exceptional properties, making it suitable for various industrial applications.

Download PDFThis advanced material is highly regarded for its strength, wear resistance, and ability to withstand extreme temperatures.

Due to its exceptional properties, SISIC Batt is widely used in various industrial processes, including:

SISIC Batt is a versatile and high-performance material that meets the demands of various industrial applications. Its unique combination of strength, wear resistance, and thermal stability ensures reliable performance in harsh environments.

RBSIC / SiSiC silicon carbide batt has excellent high temperature bearing capacity, good dimensional stability and oxidation and corrosion resistance, particularly suitable for kiln furniture in ceramic roller kiln, tunnel kiln and shuttle kiln.

RSiC and NSiC materials have excellent thermal shock resistance, deformation resistance and spalling resistance at high temperatures, and can be used for shed plates, bearing plates and backing plates in the electronic ceramics industry. The surface of the kiln furniture can be coated with alumina and zirconia as required.

| Technical index | Unit | Parameter |

|---|---|---|

| Recrystallized SiC content | % | > 99.5 |

| Bulk density | g/cm3 | 2.45-2.65 |

| Apparent porosity | % | <11 |

| Bending strength | MPa | >90-100 |

| Compression strength | MPa | >600 |

| Thermal expansion (20-1100℃) | 10-6K-1 | 4.7 |

| Thermal conductivity ( 500℃/h) | W/mK | 24 |

| Young’s modulus | GPa | 240 |

| Max working temperature | °C | 1650 |

| Acid and alkali resistance | Excellent |

Our silicon carbide tube and fitting is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition. We guarantee intact during transportation, loading and unloading, and have measures to reduce vibration and impact, so as to ensure the integrity of the product during transportation.

Our Silicon Carbide Tubes (SiC Tubes) are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Typical silicon carbide characteristics include:

Typical silicon carbide applications include:

They are used more for operation with wear at low temperature than for high temperature behavior. SiC applications are such as sandblasting injectors, automotive water pump seals, bearings, pump components, and extrusion dies that use high hardness, abrasion resistance, and corrosion resistance of carbide of silicon.

Metallurgy and power industry: The reason why these two industries are put together is mainly because the two industries have a large number of metal pipes for the transmission of coal powder, ash, mud, and the like. After using the wear-resistant elbow pipe, the advantages of strong wear resistance, long life and easy installation are immediately highlighted.

Mining industry: If the wear-resistant elbow pipe is not used, the ordinary pipe is used for the transportation of the ore powder. Due to the filling of the mine and the transportation of the concentrate powder, the wear of the pipe is relatively large, so that the life of these pipes is only about one year. After wearing elbow pipes, the life of such pipes will be extended by a factor of five.

Coal industry: If long-distance wet transport of coal is required, the pipe has the requirements of good wear resistance and high corrosion resistance, and the pipe with wear-resistant elbow can meet these requirements well.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.