SSIC Thermocouple Protection Tube

Designed to protect thermocouples from extreme temperatures and abrasion.

Explore SISIC Beams, advanced silicon carbide components known for their oxidation resistance, high bending strength, and durability in high-temperature industrial applications such as kilns and furnaces.

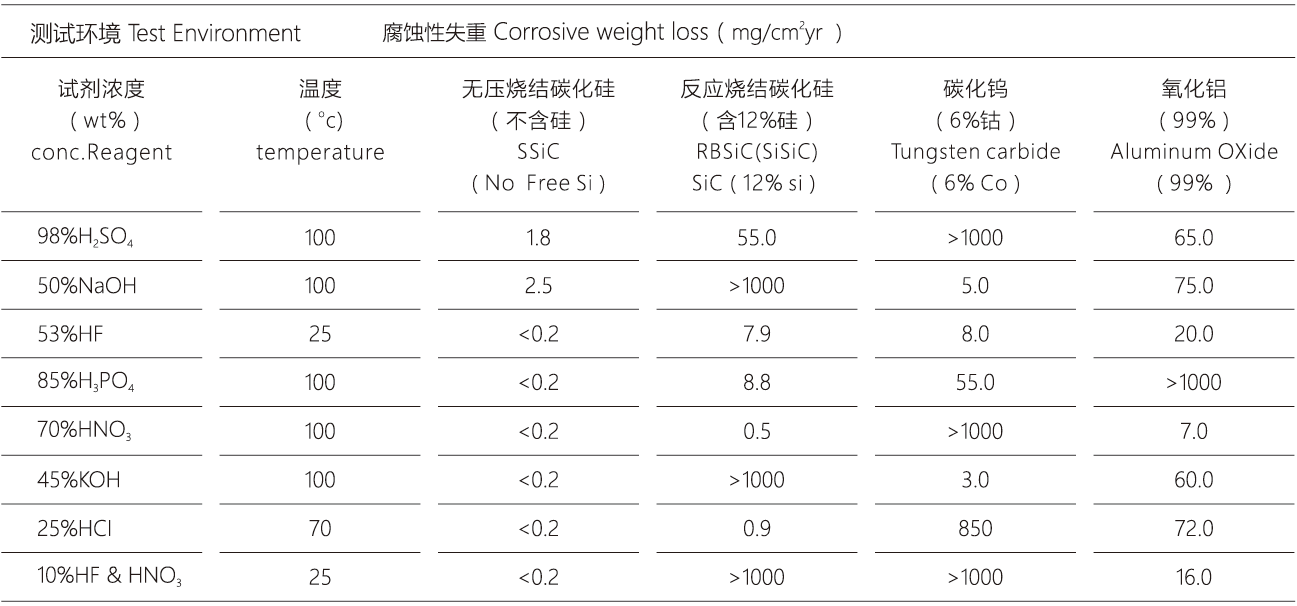

Download PDFAt present, there are two series silicon carbide products of pressureless sintering silicon carbide (SSIC) and reaction sintering silicon carbide (SISIC), which are widely used in mining, metallurgy, chemical industry, electric power, petroleum, furnace, machinery, steel, energy, environmental protection, building materials, semiconductor, aerospace and other fields. Compared with reaction bonded silicon carbide, pressureless sintered silicon carbide has higher purity, better mechanical properties, more prominent corrosion resistance(Resistant to strong acid and alkali corrosion, It is also the only ceramic material which can resistant to hydrofluoric acid corrosion), higher wear resistance, because of there’s no free silicon in the material. It can be used longer service life in environments which other materials not meet.

SISIC Beams can be manufactured in a wide range of cross-sections, wall thicknesses and lengths (up to 4 m) via slip-casting or extrusion processes.

The SISIC Beams have series of characteristic such as oxidation resistance, high bending strength, no deformation for a long application time. SISIC Beams are applicable to shuttle kiln, two-stage roller hearth kiln and other industrial kiln.

Silicon carbide (SiC) is a lightweight ceramic material with high strength properties comparable to diamond. It has excellent thermal conductivity, low thermal expansion, and is resistant to acid corrosion. Silicon carbide is an excellent ceramic material suitable for applications requiring good corrosion resistance and wear resistance.

Silicon Carbide Beam is widely used in ceramic high-temperature kiln, steel mill quenching furnace, mine material classification cyclone, large boiler and power plant desulfurization and dust removal equipment, coal slag pneumatic conveying equipment, high-tech and military equipment. Applied in machinery, metallurgy, electronics, chemical industry, iron and steel, ceramics, paper making, mineral processing, nuclear industry, national defence and so on.

Applications include structural support in high temperature processes and metrology equipment.

Extruded Silicon Carbide (SSiC) Beam with an External Rectangle and Internal Ellipse Configuration

Support and beam in the insulator furnace

Support and beam in the sanitary ware furnace

Support and beam in the foam ceramics furnace

Support and beam in the quartz furnace

Silicon carbide is formed in two ways, reaction bonding and sintering. Each forming method greatly affects the end microstructure.

Reaction bonded SiC is made by infiltrating compacts made of mixtures of SiC and carbon with liquid silicon. The silicon reacts with the carbon forming more SiC which bonds the initial SiC particles.

Sintered SiC is produced from pure SiC powder with non-oxide sintering aids. Conventional ceramic forming processes are used and the material is sintered in an inert atmosphere at temperatures up to 2000ºC or higher.

Both forms of silicon carbide (SiC) are highly wear resistant with good mechanical properties, including high temperature strength and thermal shock resistance. Our engineers are always available to best advise you on the strengths and weaknesses of each ceramic for your particular needs.

The crystal structure of the SiC ceramic wear-resistant pipe is similar to that of the diamond tetrahedral structure. It is a compound composed mainly of covalent bonds. Its hardness is high (Mohs 9.3), its performance is stable, and its physical properties are similar to diamond. It is also known as emery. Black silicon carbide crystal Hardness is the second-order material for diamonds. It is mainly used for making abrasives and grinding wheels, and partly for the production of silicon carbide ceramics.

| Size of Section(mm) | Wall Thichness(mm) | Concentrated Loading(kg·m/L) | Uniformly Distributed Loading (kg·m/L) | |||

|---|---|---|---|---|---|---|

| Bside | Hside | W Side | H Side | W Side | H Side | |

| 30 | 30 | 5 | 74 | 74 | 147 | 147 |

| 30 | 40 | 5 | 117 | 95 | 235 | 190 |

| 40 | 40 | 6 | 149 | 149 | 298 | 298 |

| 50 | 50 | 6 | 283 | 283 | 567 | 567 |

| 50 | 60 | 6 | 374 | 331 | 748 | 662 |

| 50 | 70 | 6 | 473 | 379 | 946 | 757 |

| 60 | 60 | 7 | 481 | 481 | 962 | 962 |

| 80 | 80 | 7 | 935 | 935 | 1869 | 1869 |

| 100 | 100 | 8 | 1708 | 1708 | 3416 | 3416 |

| 110 | 110 | 10 | 2498 | 2498 | 4997 | 4997 |

Silicon carbide beams of high temperature of bearing capacity of large deformation, antioxidant, not long-term use, the service life of 5-8 years. Suitable for bearing structure of tunnel kiln, shuttle kiln, roller kiln and other industrial furnace in.

Silicon carbide (SiC) is a lightweight ceramic material with high strength properties comparable to diamond.

Silicon carbide (SiC) is a synthetic crystalline mineral containing silicon and carbon, generally produced in electrical resistance furnaces at high temperatures of 1700 – 2500 °C.

It has excellent thermal conductivity, low thermal expansion and is resisitance form acids. Silicon carbide ceramic is excellent for applications requiring good erosion and abrasive resistance. Consequently, it is useful in a variety of applications including spray nozzles, shot blast nozzles, ceramic tubing and cyclone components.

A mixture of a carbon material and a silica or quartz sand, it is made to react chemically, resulting in the formation of SiC, which develops as a solid cylindrical ingot around the core, with radial layers ranging from graphite in the inside to α-SiC (the highest-grade material with coarse crystalline structure), β-SiC, metallurgical grade and finally un-reacted material on the outside, which is remelted. SiC can be produced in either black or green, depending on the raw materials used.

Once it is cooled, the SiC ingot is sorted accurately and mainly manually by skilled workers and further processed for different applications. The solid SiC material is then carefully crushed, classified, and milled again if necessary. Another option is to further chemically treat the SiC to obtain specific properties for its applications.

Silicon carbide provides benefits for high-temperature, high-voltage and high-power applications.

These include:

Thanks to its versatile properties, silicon carbide is a widely used ceramic material in many high-temperature and wear-resistant applications in many industries, such as:

We produce sintered SiC tubes, reaction bonded SiC tubes and recrystallized SiC tubes. Our recrystallized SiC products have a high purity, while our reaction bonded and sintered silicon carbide tubes have a high mechanical strength. Our silicon carbide tubes possess good wearability,a low thermal expansion coefficient, extreme corrosion resistance, wear resistance, thermal shock resistance, high hardness and self-lubricating properties.

Silicon carbide (SiC) ceramics have a set of unique physical-chemical properties, such as high hardness and mechanical stability at high temperatures, excellent thermal conductivity and low coefficient of thermal expansion, high resistance to corrosion and oxidation, wide bandgap, and others.

| Item | Recrystallized SiC | Sintered SiC | Reaction Bonded SiC |

|---|---|---|---|

| Purity of Silicon Carbide | 99.5% | 98% | > 88% |

| Max. Working Temp. (`C) | 1650 | 1550 | 1300 |

| Bulk Density (g/cm3) | 2.7 | 3.1 | > 3 |

| Appearance Porosity | < 15% | 2.5 | 0.1 |

| Flexural strength (MPa) | 110 | 400 | 380 |

| Compressive strength (MPa) | > 300 | 2200 | 2100 |

| Thermal expansion (10^-6/`C) | 4.6 (1200℃) | 4.0 (< 500℃) | 4.4 (< 500℃) |

| Thermal conductivity (W/m.K) | 35~36 | 110 | 65 |

| Main characteristics | High temp. High resistance. High purity |

Fracture Toughness | Chemical Resistance |

Reaction Bonded SiC has the lowest cost production technique with a course grain. Reaction Bonded SiC provides somewhat lower hardness and use temperature, but higher thermal conductivity. Reaction bonded silicon carbide has high strength, high hardness, hig abrasion resistance, high temperature resistance, corrosion resistance, good oxidation resistance, good thermal shock resistance, good thermal conductivity, rapid cooling and rapid heat resistance and high temperature creep resistance, etc. It can be made into beam, roller, cooling air pipe, thermocouple protection pipe, temperature measuring pipe, burner nozzle, wear-resisting parts, corrosion-resisting parts, sealing parts and a variety special-shaped structural parts.

Compared with reaction bonded silicon carbide, pressureless sintered silicon carbide has higher purity, better mechanical properties, more prominent corrosion resistance ( Resistantto strong acid and alkali corrosion, It is also the only ceramic material which can resistant to hydrofluoric acid corrosion ), higher wear resistance, because of there’s no free silicon in the material can be used in other materials can not meet the environment, longer service life.

At present, the use of our company’s high wear-resistant ceramic lined steel pipe dozens of thermal power plant practice shows that: ceramic lined steel pipe anti-wear ability, anti-fluid erosion ability.

And it has developed rapidly. When transporting the materials with the harder abrasion (such as ash dregs, slag, coal powder, mining dregs, the rest mines, cement, etc), it will exit the problem that the abrasion of pipes is too rapid. Especially, the abrasion of bent pipes is greatly more rapid.

When transporting the special abrasion materials or erosive materials, it will exit the problem that the damage of pipes is too rapid.

SiC Ceramic lined pipe and the traditional steel pipe, wear-resistant alloy cast steel pipe, cast stone pipe and steel, steel and other rubber pipe is essentially different. Ceramic lined pipe is the outer layer of steel, the inner layer is RBSiC ceramic. Moh’s hardness of up to 13. Wear resistance than carbon steel pipe more than 30 times higher.

In a duct, the elbow wear the fastest, in practice, Ceramic lined pipe used after 1 to 2 years to open the observation and measurement, the composite layer are no obvious wear or tear off, ceramic-coated steel pipe wear Than the thick-walled wear-resistant cast steel pipe increased by nearly 10 times.

Silicon carbide (SiC) is a lightweight ceramic material with high strength properties comparable to diamond. It has excellent thermal conductivity, low thermal expansion, and is resistant to acid corrosion.

Silicon carbide is an excellent ceramic material suitable for applications requiring good corrosion resistance and wear resistance.

Our silicon carbide tube and fitting is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition. We guarantee intact during transportation, loading and unloading, and have measures to reduce vibration and impact, so as to ensure the integrity of the product during transportation.

Our Silicon Carbide Tubes (SiC Tubes) are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Typical silicon carbide characteristics include:

Typical silicon carbide applications include:

They are used more for operation with wear at low temperature than for high temperature behavior. SiC applications are such as sandblasting injectors, automotive water pump seals, bearings, pump components, and extrusion dies that use high hardness, abrasion resistance, and corrosion resistance of carbide of silicon.

Metallurgy and power industry: The reason why these two industries are put together is mainly because the two industries have a large number of metal pipes for the transmission of coal powder, ash, mud, and the like. After using the wear-resistant elbow pipe, the advantages of strong wear resistance, long life and easy installation are immediately highlighted.

Mining industry: If the wear-resistant elbow pipe is not used, the ordinary pipe is used for the transportation of the ore powder. Due to the filling of the mine and the transportation of the concentrate powder, the wear of the pipe is relatively large, so that the life of these pipes is only about one year. After wearing elbow pipes, the life of such pipes will be extended by a factor of five.

Coal industry: If long-distance wet transport of coal is required, the pipe has the requirements of good wear resistance and high corrosion resistance, and the pipe with wear-resistant elbow can meet these requirements well.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.