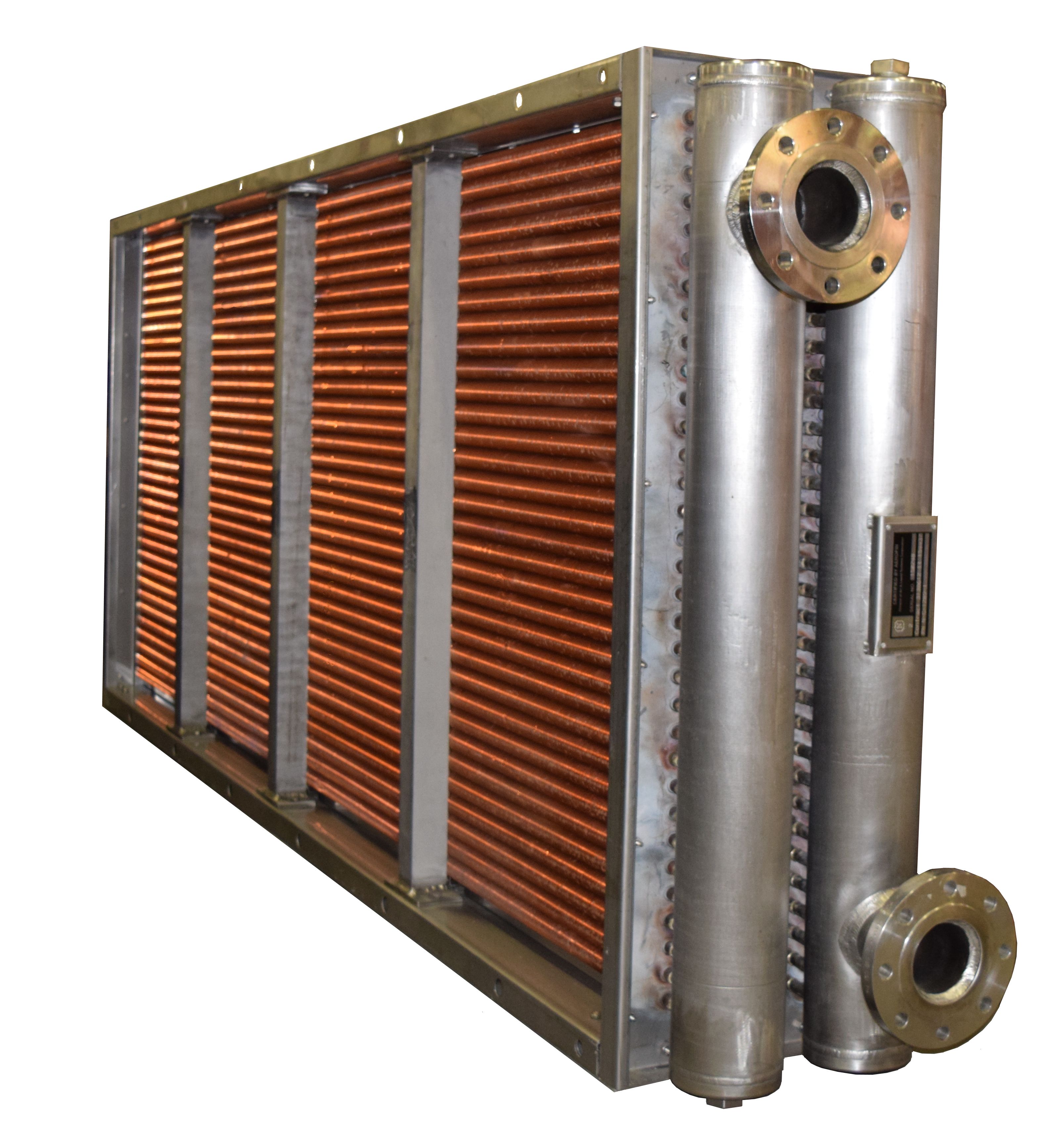

Crimped Fin Tube

Crimped fin tubes for enhanced heat transfer and mechanical strength.

Spiral fin construction is a specialized technique used in the manufacturing of finned tubes for efficient heat transfer in various industrial applications.

Spiral Fin coils are used for heating, cooling and dehumidifying. In addition to water, a variety of other heating and cooling media, such as glycol and brine solutions, thermal oils, and refrigerants for DX applications, can be used.

Fins are tension wound on individual tubes to minimise thermal contact resistance and air friction. The tapered fin design provides maximum fin-to-tube contact for optimum heat transfer. Individually finned tubes allow the tubes to move freely, eliminating stress on the tube and fin-to-tube bond caused by thermal cycling. Material thicknesses on the fins can range from 0.010" to 0.030" depending on the material used.

All coils feature 5/8″ OD or 1″ OD seamless copper tubes conforming to ASTM specifications. Standard 5/8″ OD tube wall thickness is 0.020” and standard 1″ OD tube wall thickness is 0.035”. Heavier wall tubing is available up to 0.065” for 5/8” tubing and 0.134” for 1” tubing depending on the material being used. Copper-nickel, aluminum, stainless steel, and carbon steel are available material options.

All copper based tubes are brazed with certain applications such steam heating coils using silver braze. Other tube materials, such as stainless or carbon steel will require welded joints. Coils featuring removable or box style headers will feature roller-expanded tube joints. Aerofin brazers and welders are ASME qualified.

Coil casings are heavy gauge galvanized steel for high strength and durability, and as a standard are double flanged for coil stacking. Stainless steel, aluminum, and other casing materials are available material options. Special configurations such as welded casings for airtight applications are available.

Our factory standard coil test is performed with 300 psig air under water; however, some types of coils may require different testing parameters. Coils with removable headers will be tested hydrostatically to 150 psig. Higher design and test pressures are available for special applications.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.