Bimetallic Composite Pipe

Read more

API 5L clad steel pipe refers to a type of steel pipe that consists of two different layers of material bonded together.

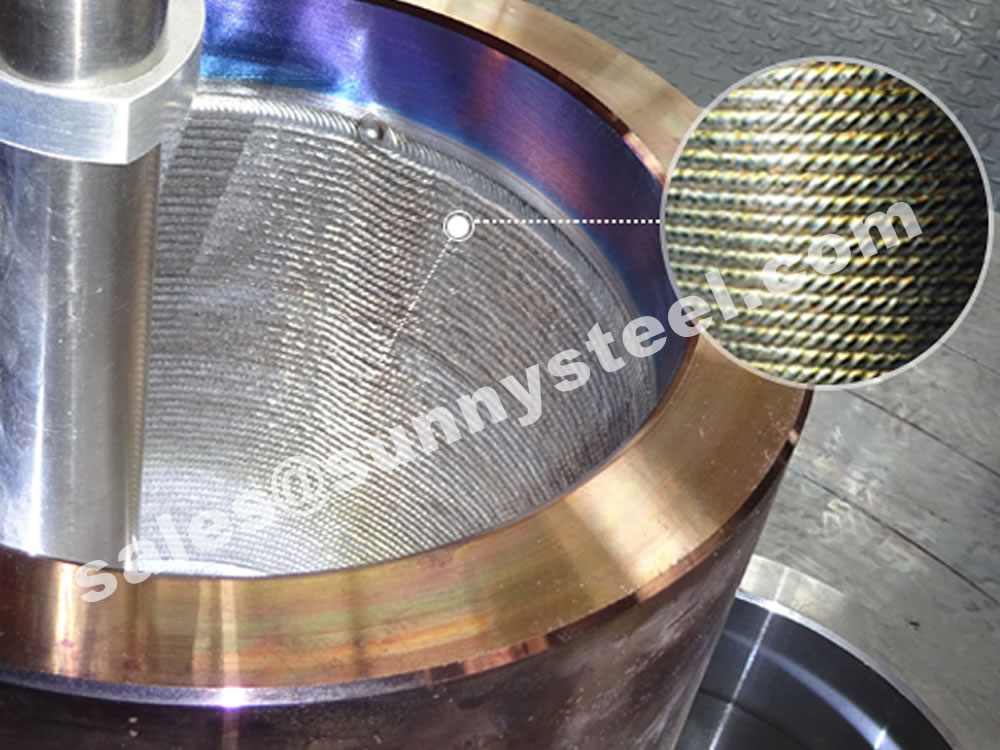

API 5L clad steel pipe is a type of steel pipe with two or more layers of different materials bonded together. The inner layer is typically made of carbon steel, while the outer layer is made of a corrosion-resistant alloy, such as stainless steel or a nickel-based alloy. This design ensures corrosion resistance on the outside while maintaining the strength and durability of the inner layer. API 5L clad steel pipes are widely used in industries such as oil and gas, chemical, power generation, and water treatment.

API 5L clad steel pipes are engineered for reliability in harsh environments. The inner carbon steel layer provides strength and durability, while the corrosion-resistant outer layer ensures longevity and reduced maintenance. This combination makes API 5L clad steel pipes a preferred choice for applications in oil and gas, chemical, and other industries.

Clad steel pipes have been in use since the early 1900s. Initially used in bridge construction, these pipes were joined using welding techniques. However, welding had drawbacks, such as cracking due to differing coefficients of expansion. This issue was resolved with the roll bonding process, allowing the two layers to expand and contract uniformly.

The use of clad steel pipes expanded in the 1940s for oil and gas pipelines, where corrosion resistance was crucial. The roll bonding process was adapted and standardized, eventually leading to the development of the API 5L standard.

The API 5L standard, developed by the American Petroleum Institute (API), outlines requirements for the manufacture of clad steel pipes used in oil and gas pipelines. It covers materials, design, fabrication, assembly, inspection, testing, and welding. Key points include:

API 5L clad steel pipes offer exceptional performance in challenging environments:

API 5L clad steel pipes are widely used in:

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.