ASTM A333 Grade 1

Read more

ASMT A333 Grade 1 seamless and welded pipes shall be treated to control their microstructure.

Download PDFASTM A333 grade 1 is a carbon-based alloy that can be used at low temperatures. You can find manganese, phosphorus and sulphur all in the chemical composition of A333 carbon steel pipe. In A333 gr b pipe, the strength of each grade is different.

ASTM A333 grade 1 is constructed from carbon-based alloy for low temperature service. The chemical composition of the A333 carbon steel pipe includes – manganese, phosphorus and sulphur. The tensile strength and yield strength for the A333 gr b pipe is variable among its grades. For example, the tensile strength is 380 MPa and yield strength is 205 MPa for grade 1. The tensile strength is 450 MPa and yield strength is 240 MPa for grade 3. While the tensile strength is 415 MPa and yield strength is 240 MPa for ASTM A333 grade 1 pipe schedule. The pipes made from SA333 gr 1 material are meant for low temperature applications. The A333 grade 1 pipe is available in either welded, ERW, CDW, fabricated or seamless type. While producing welded pipes, it is not necessary to add filler metals during the operation. These carbon steel A333 grade 1 pipes are surface treated. The pipe ends of the A333 Gr 1 seamless pipe could be bevelled, plain ended or threaded, depending on the requirement of the buyer.

Some of the surface treatments include a coating or finishing by Oil-dip, Phosphating, Varnish, Passivation or Shot Blasting. They could also be anodized or finished polish. The treatment gives the surface of the A333 gr 1 smls pipe a smooth and flawless appearance. ASTM A333 grade 1 pipe can be conventionally formed, cold-worked and welded. The A333 grade 1 pipe can be hot worked, but they can’t be hot worked below 1500 degrees F. The ASTM A333 grade 1 pipe equivalent pipe is used in the transportation of Chemical, Water and Gas. SA333 gr1 pipe finds application in building or construction work, where they are used to deliver concrete pumps. We are one of the oldest A333 grade 1 pipe manufacturer.

Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements. ASTM A333 Grade 1 is the part of standard covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. ASTM A333 Grade 1 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. Seamless and Welded Steel Pipe size for Low-Temperature Service:

| Compositions | Data |

|---|---|

| Carbon(max.) | 0.30 |

| Manganese | 0.40–1.06 |

| Phosphorus(max.) | 0.025 |

| Sulfur(max.) | 0.025 |

| Silicon | … |

| Nickel | … |

| Chromium | … |

| Other Elements | … |

| Properties | Data |

|---|---|

| Yield strength(min) | 205Mpa |

| Tensile strength(min) | 380Mpa |

| Elongation(%) | 35 |

| ℉ | ℃ |

|---|---|

| -50 | -45 |

ASTM A333 is the standard specification for seamless and welded carbon and alloy steel pipe for low temperature service or other applications requiring notch toughness.

Several grades of ferritic steel are included. Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse affect on low-temperature impact properties. The pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. All seamless and welded pipes shall be treated to control their microstructure. Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements.

ASTM A333 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. All seamless and welded pipes shall be treated to control their microstructure. Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements. Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse affect on low-temperature impact properties.

ASTM A333 steel pipe production includes a series of visual surface imperfections to guarantee that they have been properly manufactured. ASTM A333 steel pipe shall be subject to rejection if surface imperfections acceptable are not scattered, but appear over a large area in excess of what is considered a workmanlike finish. The finished pipe shall be reasonably straight.

Surface imperfections that penetrate more than 12½ % of the nominal wall thickness or encroach on the minimum wall thickness shall be considered defects. ASTM A333 steel pipe with such defects shall be given one of the following dispositions:

ASTM A333 Grade 6 pipe is a low-temperature carbon steel pipe that is typically used in applications where the pipe will be exposed to temperatures below -45°C. Because of its superior notch toughness, it performs well in cryogenic conditions and has demonstrated durability at temperatures as low as -452°F. This makes it the perfect candidate for applications where the pipe will be subject to cold temperatures throughout construction and/or operation.

A333 Seamless Pipe (ASME S/A-333) comes in nominal pipe sizes 1/4″ to 24″ O.D.

Pipe dimensions range from 1/2″ to 24″ O.D. for A333 welded pipes (ASME S/A-333).

Carbon and alloy steel pipe with a nominal (average) wall thickness intended for low temperature operation is covered by ASTM A333. There are several ferritic steel grades included in this standard. A106 GR. B Carbon Steel Seamless Pipes Some product sizes may not be available under this specification because heavier wall thicknesses harm low-temperature impact properties.

The difference between ASTM A333 and ASTM A106 is that ASTM A333 is a low-temperature carbon steel pipe that can be used as a structural pipe, while ASTM A106 is a non-structural carbon pipe that is used in high-temperature applications.

The ASTM A106 Gr.B carbon steel Pipe is valued for its high tensile strength and toughness, high oxidation resistance, and prolonged durability. Additionally, the Seamless Pressure ASTM A106 Pipe has wide applications in industries such as the gas and oil industry, water, heating, pipeline construction, and many others.

However, the ASTM A106 Gr.B carbon steel Pipe should be used only at temperatures less than 430°C, as exceeding this temperature can result in a reduction in its mechanical properties. The pipe is therefore not suitable for very high-temperature services.

With years of expertise, we provide a diverse array of steel tube processing options. From sawing and machining tube blanks to intricate bending and upsetting operations, we actively assist you throughout your projects.

Our capabilities extend to eccentricity reduction and concentricity enhancement through turning and grinding. We excel in creating complex geometries using processes like rotary swaging and axial forming. Additionally, we offer property modifications via partial heat treatment, ensuring tailored solutions for your specific needs.

Variable wall thicknesses

Drilling / stamping / lasering

Peeling / roller burnishing

Cold forming

Cutting

Beveling

Deburring

Thread rolling / threading

Partial hardening

Turning / milling / grinding

Reducing / expanding

Swing

Alloy steel pipes are ideally suitable for chemical, petrochemicals, and other energy-related applications.

The alloy steel pipe adopts high quality carbon steel, alloy structural steel and stainless & heat resisting steel as raw material through hot rolling or cold drawn to be made.

Alloy steel can be used in process area where carbon steel has limitation such as

As an important element of steel products, alloy steel pipe can be divided into seamless steel pipe and welded steel pipe according to the manufacturing technique and tube billet shape.

Here you can see the common alloy steel grade that you will come across.

There are many kinds of materials used for transport in industrial production. Specifically we will have more choices and it is not limited to the use of alloy steel pipe. But even in the face of more choices, many people tend to choose alloy steel pipe. People make their own choices will have their own reasons. This means the alloy steel pipe application has its own advantages. Compared with transmission lines made of other materials, after it meets the basic application requirements, its quantity is lighter. Then in the practical application of alloy steel pipe, it will have more advantages because of this. Besides its physical characteristic advantage, it also has economic advantages. The wide application of alloy steel pipe is with kinds of reasons. So in practical usage, we can exploit the advantages to the full, in this way can we get more profits in these applications of alloy steel pipe.

The transportation of kinds of gases or liquids in production needs to rely on alloy steel pipe. This shows that the actual role of alloy steel pipe application is important. High temperature resistant and low temperature resistant is the tolerance of temperature. In the practical application of alloy steel pipe, there will be many materials need to be transported. However their temperatures are not the same. So this can be the basic requirement to alloy steel pipe. It needs more corrosion resistance. Corrosion resistant material is the best material during transporting, because it is corrosion resistant. So it can be used in more occasions. And it is definitely very convenient for users.

Can be 100% recycled, environmentally friendly, energy-saving, resource conservation, national strategy, national policy to encourage the expansion of the field of application of high-pressure alloy pipe. Of alloy steel pipe total consumption accounted steel in the proportion is only half of the developed countries, to expand the field of use of the alloy steel pipe to provide a wider space for the development of the industry. The future needs of the average annual growth of China’s high-pressure alloy steel pipe long products up to 10-12%.

Alloy Steel pipe contains substantial quantities of elements other than carbon such as nickel, chromium, silicon, manganese, tungsten, molybdenum, vanadium and limited amounts of other commonly accepted elements such as manganese, sulfur, silicon, and phosphorous.

Our team of experienced sales specialists proudly partners with gas and chemical processors, power generation plants, oil refineries, and related industries to offer piping components and value-added services.

The biggest advantages of alloy steel pipe can be 100% recycled, environmentally friendly, energy-saving, resource conservation, national strategy, national policy to encourage the expansion of the field of application of high-pressure alloy pipe. Of alloy tube total consumption accounted steel in the proportion is only half of the developed countries, to expand the field of use of the alloy tube to provide a wider space for the development of the industry. According to the Chinese Special Steel Association alloy pipe Branch Expert Group, the future needs of the average annual growth of China’s high-pressure alloy pipe long products up to 10-12%.

Chemical composition inspection, mechanical properties test(tensile strength,yield strength, elongation, flaring, flattening, bending, hardness, impact test), surface and dimension test,no-destructive test, hydrostatic test.

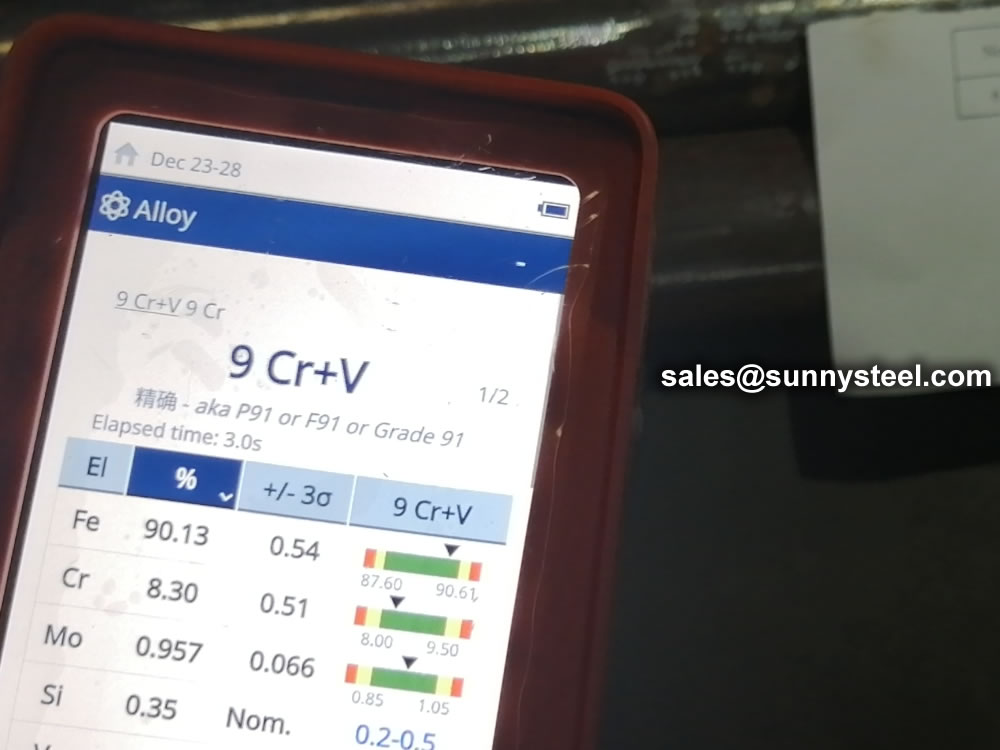

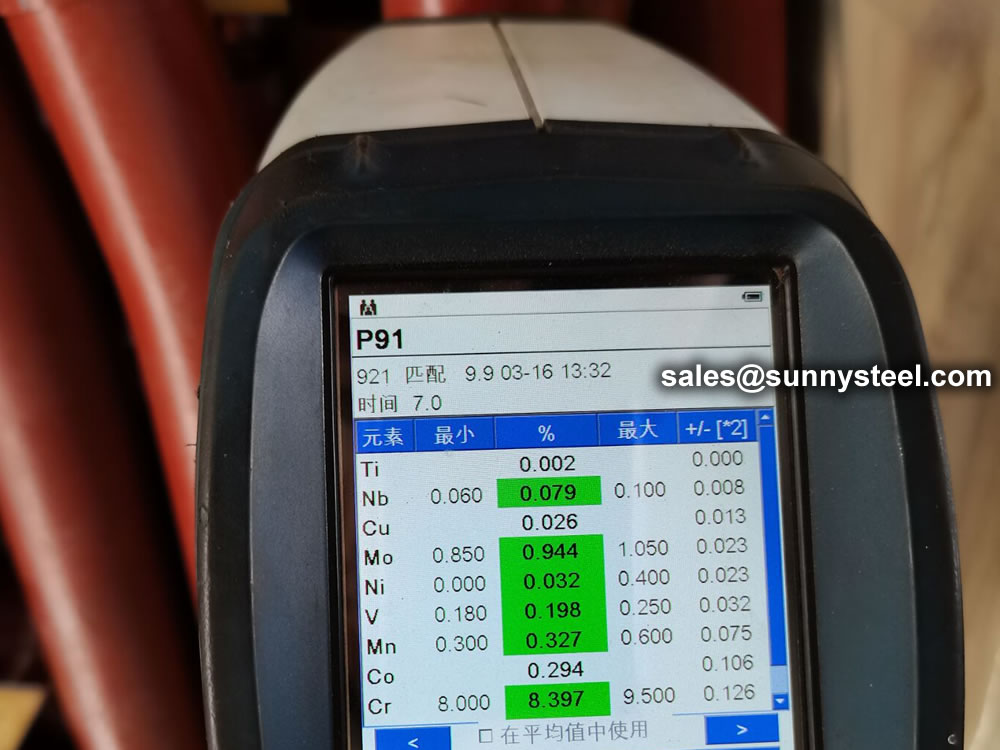

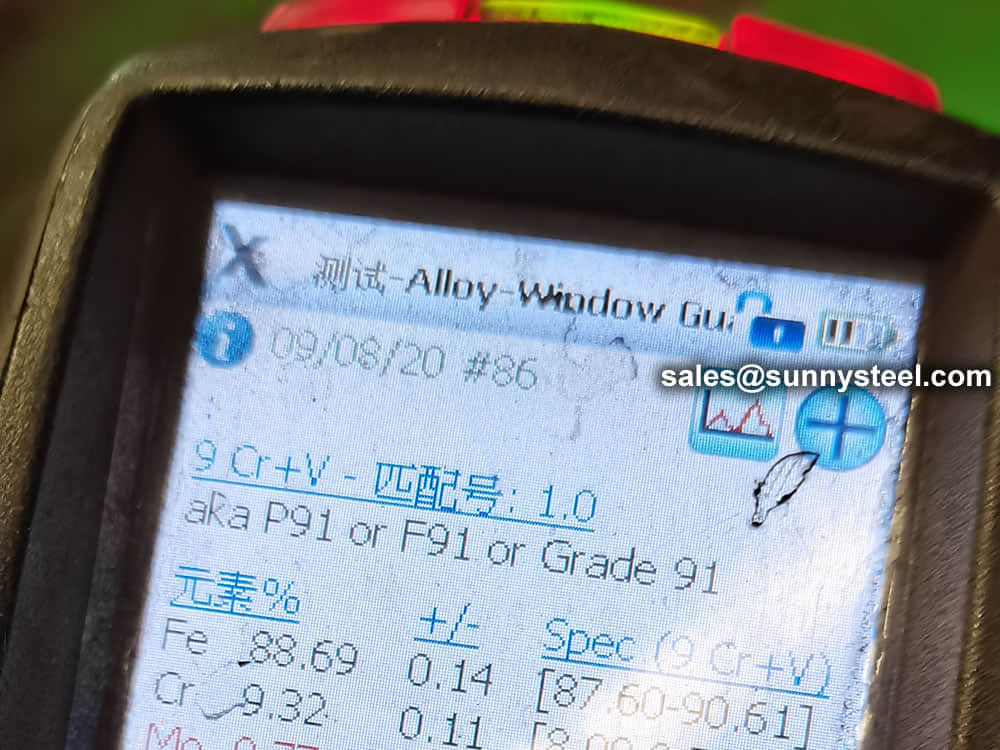

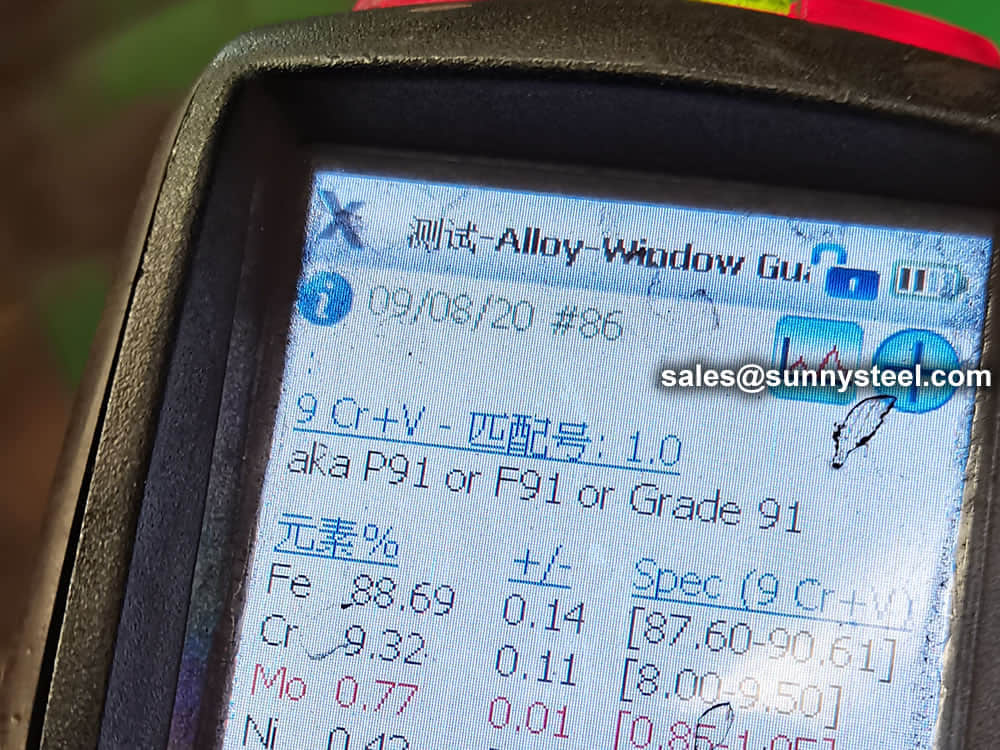

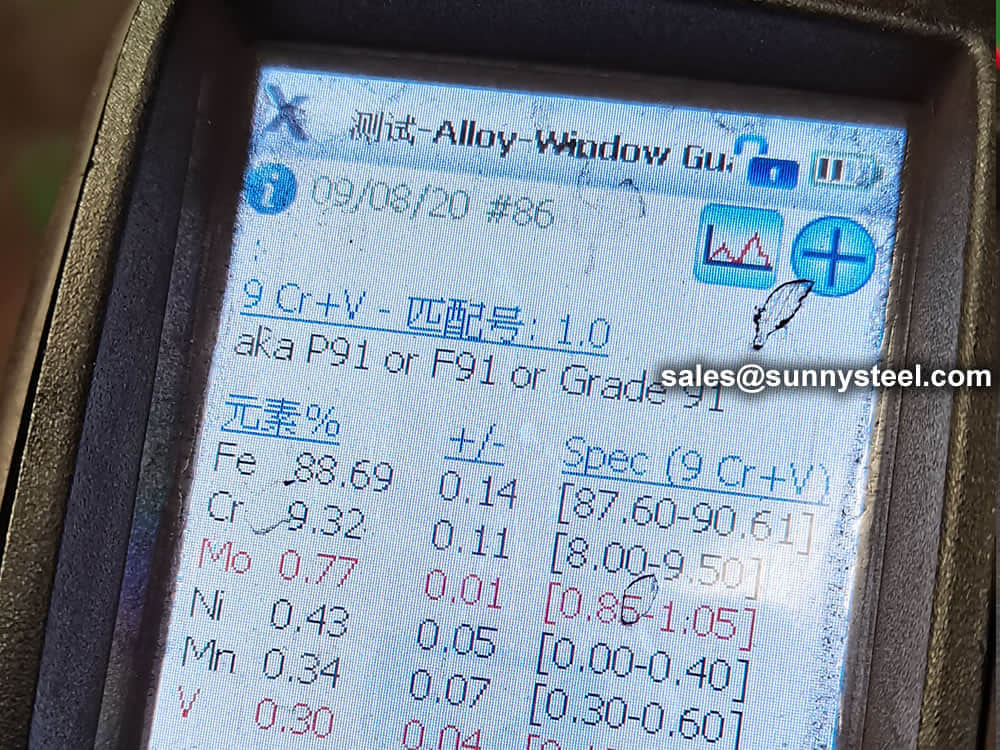

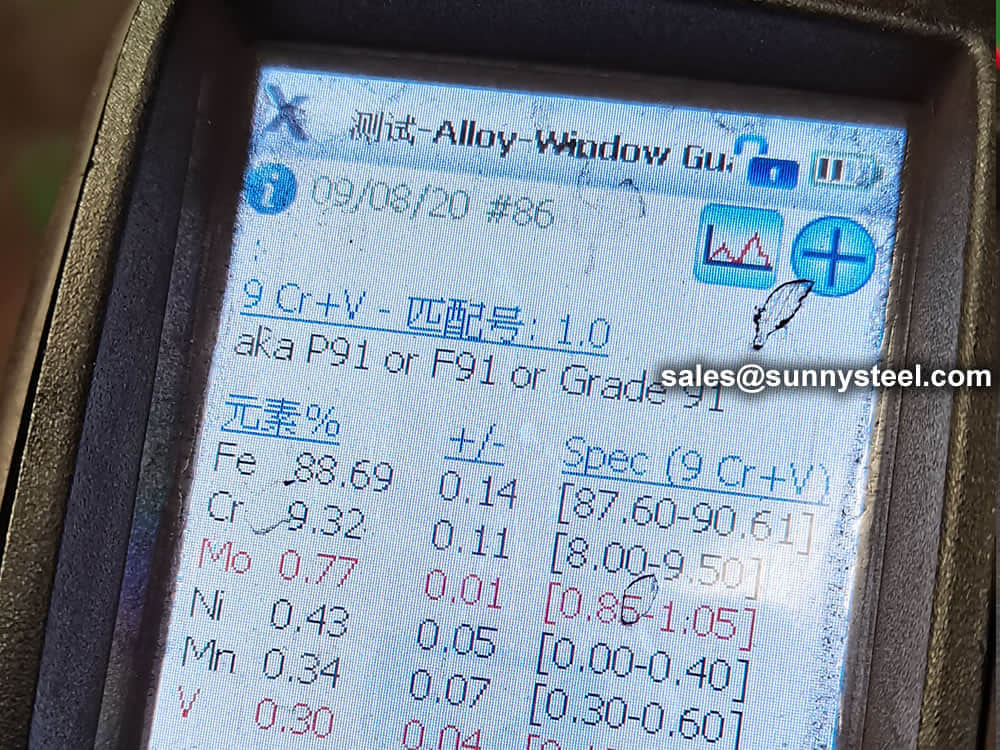

identification of the chemical composition of the metal used to manufacture the fitting. Uses PMI sensors, including X-ray fluorescence or optical emission spectrometry.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

The general cold strip mills, volume should go through continuous annealing (CAPL unit) to eliminate cold hardening and rolling stress, or batch annealing reach the mechanical properties of the corresponding standard specifies. Cold rolled steel surface quality, appearance, dimensional accuracy better than hot-rolled plate, and right-rolled thin product thickness is about 0.18mm, so the majority of users favor.

Cold rolled steel coil substrate products deep processing of high value-added products. Such as electro-galvanized, hot dip galvanized, electro-galvanized fingerprint resistant, painted steel roll damping composite steel, PVC laminating steel plates, etc., so that the excellent quality of these products has a beautiful, high resistance to corrosion, has been widely used.

Cold rolled steel coil finishing after annealing, cut the head, tail, trimming, flattening, smooth, heavy volume, or longitudinal clipboard. Cold-rolled products are widely used in automobile manufacturing, household electrical appliances, instruments, switches, buildings, office furniture and other industries. Steel plate strapping package weight of 3 to 5 tons. Flat sub-volume typically 3 to 10 tons / volume. Coil diameter 6m.

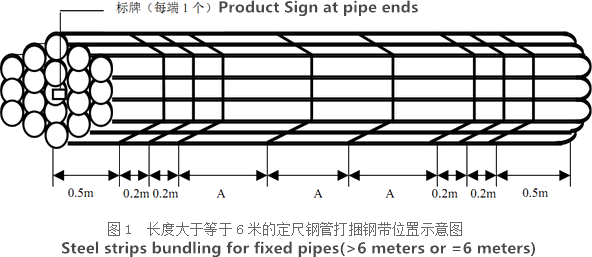

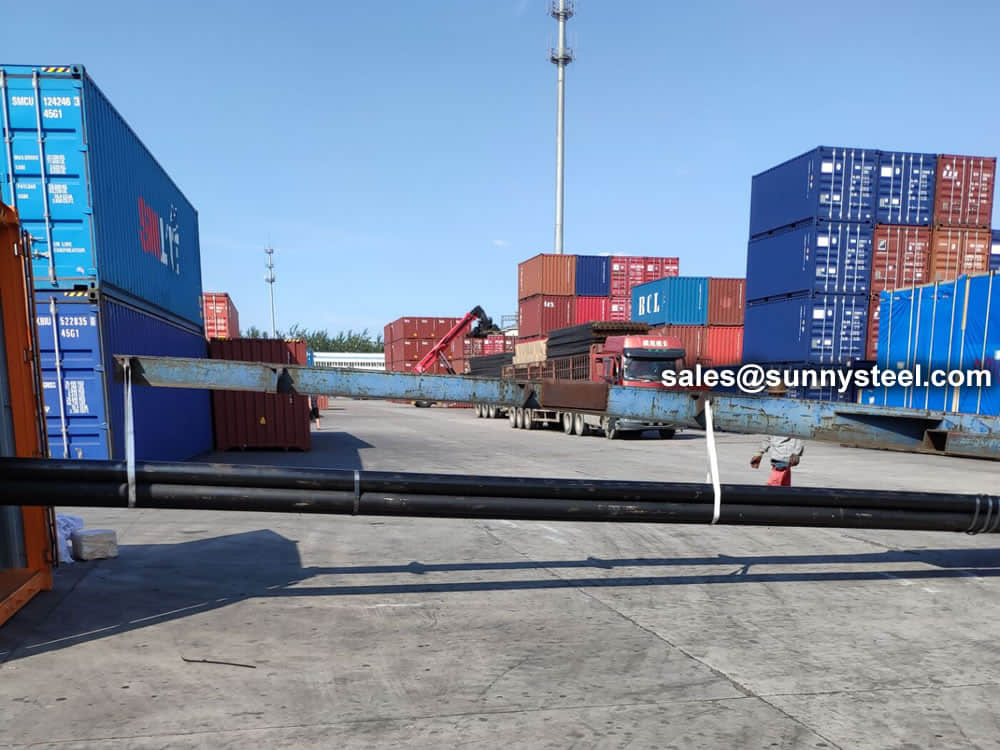

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.

Our team of experienced sales specialists proudly partners with gas and chemical processors, power generation plants, oil refineries, and related industries to offer piping components and value-added services.

Alloy steels are made by combining carbon steel with one or several alloying elements, such as manganese, silicon, nickel, titanium, copper, chromium and aluminum. These metals are added to produce specific properties that are not found in regular carbon steel. The elements are added in varying proportions (or combinations) making the material take on different aspects such as increased hardness, increased corrosion resistance, increased strength, improved formability (ductility); the weldability can also change.

| Grade | Tensile Strength (MPa) | Yield Point (MPa) | Elongation (%) | |

|---|---|---|---|---|

| Y | X | |||

| ASTM A333 Grade 1 | ≥380 | ≥205 | ≥35 | ≥25 |

| ASTM A333 Grade 3 | ≥450 | ≥240 | ≥30 | ≥20 |

| ASTM A333 Grade 4 | ≥415 | ≥240 | ≥30 | ≥16.5 |

| ASTM A333 Grade 6 | ≥415 | ≥240 | ≥30 | ≥16.5 |

| ASTM A333 Grade 7 | ≥450 | ≥240 | ≥30 | ≥22 |

| ASTM A333 Gr. 8 | ≥690 | ≥515 | ≥22 | |

| ASTM A333 Grade 9 | ≥435 | ≥315 | ≥28 | |

| ASTM A333 Grade 10 | ≥550 | ≥450 | ≥22 | |

| ASTM A333 Grade 11 | ≥450 | ≥240 | ≥18 | |

*The elongation values are furnished on the basis of standard round 2 inch or 50 mm(or 4D) specimens.

*Elongation of Grade 11 is for all walls and small sizes tested in full section.

| Grade | Chemical Composition (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V | Al | |

| Grade 1 | ≤0.30 | 0.40-1.06 | ≤0.025 | ≤0.025 | |||||||

| Grade 3 | ≤0.19 | 0.18-0.37 | 0.31-0.64 | ≤0.025 | ≤0.025 | 3.18-3.82 | |||||

| Grade 4 | ≤0.12 | 0.18-0.37 | 0.50-1.05 | ≤0.025 | ≤0.025 | 0.44-1.01 | 0.47-0.98 | 0.40-0.75 | 0.04-0.30 | ||

| Grade 6 | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.025 | ≤0.025 | ||||||

| Grade 7 | ≤0.19 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤0.025 | 2.03-2.57 | |||||

| Grade 8 | ≤0.13 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤0.025 | 8.40-9.60 | |||||

| Grade 9 | ≤0.20 | 0.40-1.06 | ≤0.025 | ≤0.025 | 1.60-2.24 | 0.75-1.25 | |||||

| Grade 10 | ≤0.20 | 0.10-0.35 | 1.15-1.50 | ≤0.03 | ≤0.015 | ≤0.15 | ≤0.25 | ≤0.015 | ≤0.50 | ≤0.12 | ≤0.06 |

| Grade 11 | ≤0.10 | ≤0.35 | ≤0.6 | ≤0.025 | ≤0.025 | ≤0.50 | 35.0-37.0 | ≤0.50 | |||

*For Grade 1 and 6, each reduction of 0.01% C below 0.30%, an increase of 0.05 % Mn above 1.06 % would be permitted to a max. of 1.35%.

*For Grade 6, the limit for columbium may be increased up to 0.05 % on heat analysis and 0.06 % on product analysis.

*Generally, the carbon equivalent C.E = [C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15] shall not exceed 0.43% by heat analysis.

| No. | Order No. | Size description | ||

|---|---|---|---|---|

| O.D. /mm | W.T. /mm | Legnth /m | ||

| 1 | A333 Gr.6 A333 Gr.6/X42NS | 10-127 | 1-20 | 6-12.0 |

| 42-114.3 | 3.5-6 | 6-12.2 | ||

| 42-114.3 | 6-12 | 6-12.2 | ||

| 114.3-180 | 3.8-8 | 6-12.2 | ||

| 114.3-180 | 8-22 | 6-12.2 | ||

| 68-180 | 10-14 | 6-12.2 | ||

| 69-254 | 14-55 | 6-12.2 | ||

| 140-340 | 6-8 | 6-12.2 | ||

| 140-368 | 8-42 | 6-12.2 | ||

| 318-720 | 14-50 | 4-12.5 | ||

| 2 | A333 Gr.6/X52QS | 42-114.3 | 3.5-12 | 6-12.2 |

| 114.3-180 | 3.8-22 | 6-12.2 | ||

| 68-254 | 10-40 | 6-12.2 | ||

| 140-368 | 6-40 | 6-12.2 | ||

| 318-720 | 14-40 | 4-12.5 | ||

| 140-368 | 6-25 | 6-12.2 | ||

| 318-720 | 14-25 | 4-12.5 | ||

| 3 | 16MnDG | 10-127 | 1-20 | 6-12.0 |

| 42-114.3 | 3.5-12 | 6-12.2 | ||

| 114.3-180 | 3.8-22 | 6-12.2 | ||

| 68-254 | 10-55 | 6-12.2 | ||

| 140-368 | 6-42 | 6-12.2 | ||

| 318-720 | 14-120 | 4-12.5 | ||

| Crade | The lowest temperature for strike test | |

|---|---|---|

| ℉ | ℃ | |

| ASTM A333 Grade 1 | -50 | -45 |

| ASTM A333 Grade 3 | -150 | -100 |

| ASTM A333 Grade 4 | -150 | -100 |

| ASTM A333 Grade 6 | -50 | -45 |

| ASTM A333 Grade 7 | -100 | -75 |

| ASTM A333 Grade 8 | -320 | -195 |

| ASTM A333 Grade 9 | -100 | -75 |

| ASTM A333 Grade 10 | -75 | -60 |

Commonly used alloying elements and their effects are listed in the table given below.

| Alloying Elements | Effect on the Properties |

|---|---|

| Chromium | Increases Resistance to corrosion and oxidation. Increases hardenability and wear resistance. Increases high temperature strength. |

| Nickel | Increases hardenability. Improves toughness. Increases impact strength at low temperatures. |

| Molybdenum | Increases hardenability, high temperature hardness, and wear resistance. Enhances the effects of other alloying elements. Eliminate temper brittleness in steels. Increases high temperature strength. |

| Manganese | Increases hardenability. Combines with sulfur to reduce its adverse effects. |

| Vanadium | Increases hardenability, high temperature hardness, and wear resistance. Improves fatigue resistance. |

| Titanium | Strongest carbide former. Added to stainless steel to prevent precipitation of chromium carbide. |

| Silicon | Removes oxygen in steel making. Improves toughness. Increases hardness ability |

| Boron | Increases hardenability. Produces fine grain size. |

| Aluminum | Forms nitride in nitriding steels. Produces fine grain size in casting. Removes oxygen in steel melting. |

| Cobalt | Increases heat and wear resistance. |

| Tungsten | Increases hardness at elevated temperatures. Refines grain size. |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.