Basalt lined pipe

Durable basalt lined pipes for high-temperature and abrasive environments.

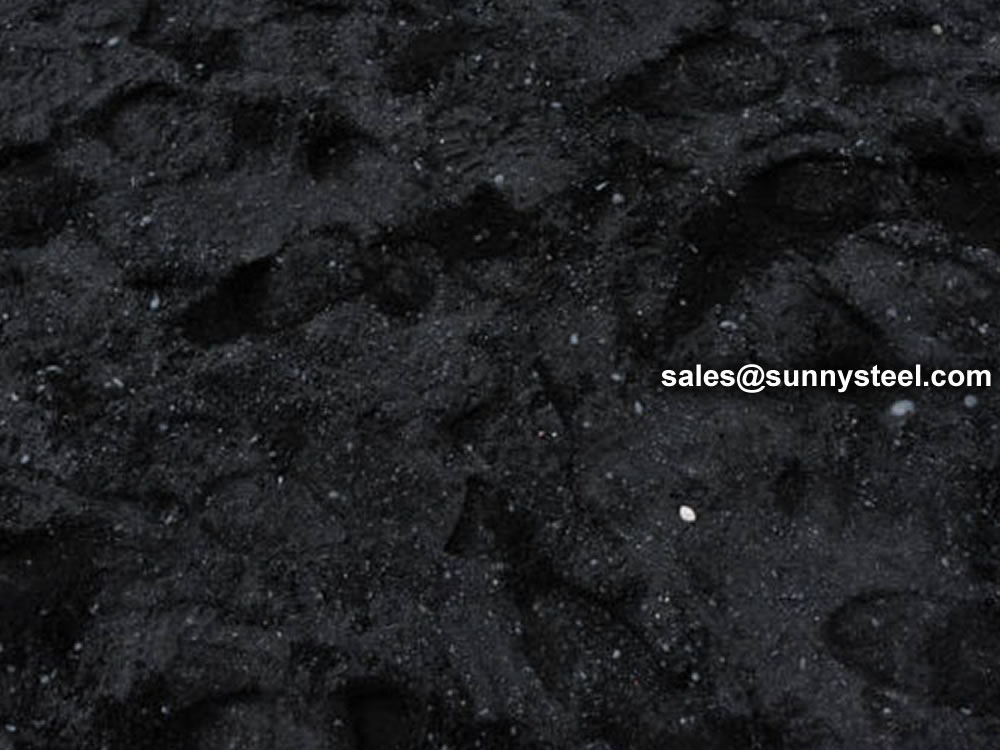

Cast basalt aggregate is a type of aggregate made from cast basalt, a material produced by melting basalt rock and then casting it into various forms.

Cast basalt aggregate refers to crushed basalt stones that are used as a component in the production of cast basalt products.

Our durable basalt gravel offers superior performance for versatile infrastructure solutions.

Basalt is a volcanic rock that is formed from the rapid cooling of lava. It is known for its high strength, durability, and thermal resistance, making it suitable for various applications in industries like construction, transportation, and manufacturing.

In the production of cast basalt products, such as pipes, tiles, and linings, the basalt aggregate is mixed with a binding agent, usually epoxy resin or cementitious material. The mixture is then cast into a desired shape and cured to form a solid product.

Cast basalt products, reinforced with the aggregate, exhibit excellent resistance to abrasion, corrosion, and impact. They are commonly used in applications where high wear and chemical resistance are required, such as in lining chutes, hoppers, pipelines, and tanks.

Overall, cast basalt aggregate plays a crucial role in the manufacturing of cast basalt products, providing them with the desirable properties that make them suitable for heavy-duty industrial applications.

When it comes to basalt, we generally only know that it is often used to make stone aggregates, and it is an ideal aggregate raw material. But in fact, basalt can also be made into fine powder and used as a mixing material for cement. The effect is ideal, and it can also save coal consumption, which has good economic and social benefits. Guilin Hongcheng basalt vertical mill will introduce you.

Basalt is a good raw material for producing cast stone. Cast stone is a material made of basalt after melting, casting, crystallization, and annealing. It is harder and more wear-resistant than alloy steel, and stronger than lead and .

Basalt is a volcanic rock, a durable and hard stone. Basalt sand and stone are available in every degree.

Basalt is a type of volcanic rock formed by the cooling and solidification of molten lava that come out of the cracks of the earth's crust. Basalts are generally dark black in color. Basalt is a hard and hard stone and it is used in ballast, gravel and sandblasting industry. It is used in basalt sandblasting industry that does not contain free silica. Basalt is a rock with a hardness of 6.5 mohs and a density of 2.77 gr / cm3, which contains 45-50% SiO2. Basalt sand is used in scraper in the range of 0.5-1.6mm, 1.0-2.0mm and 1.5-2.7mm.

Casting as a method of basalts processing consists of melting of the aggregate in a furnace at temperatures in the range of 1400 Deg C, pouring into the mold, centrifugal casting and subsequently cooling of the castings, with relaxation of internal stress.

cast basalt aggregate 5-10mm

Usually, stones in engineering are classified according to gradation (particle size), there are two kinds, one is continuous gradation and the other is single-grain grade.

cast basalt aggregate 5-15mm

Basalt is a common mineral in the earth's crust and belongs to the nature of volcanic rock. The main components are silicon oxide, aluminum oxide, iron oxide, etc. It is usually black, and sometimes it is gray-green, dark purple, dark red, etc. The texture is relatively dense, and its specific gravity is heavier than that of granite, limestone, and shale. Basalt has high durability, many joints, is not easy to be mined in large blocks, and is rarely used as decorative stone. Porous basalt is also called pumice. When mixed into concrete, it can reduce weight, be strong and durable, and have the functions of sound insulation and heat insulation. It is a good aggregate material for lightweight concrete in high-rise buildings.

Basalt is also the best material among the stones used in the construction of roads, railways, and airport runways. It has the advantages of strong compression resistance and corrosion resistance, wear resistance, low crushing value, less draft, and poor conductivity. In addition to construction purposes, basalt is also an ideal raw material for cast stone. It can form alloy steel, which is harder and more wear-resistant than lead and rubber. It can also be used as a lubricant in an advanced steel casting process to prolong the cast film. Lifespan; it can also be drawn into glass filaments, and the basalt glass filament cloth made of it is stronger in alkali resistance and high temperature resistance than ordinary glass filament cloth. At the same time, it is also widely used in garden landscape, mainly as rockery, bonsai and so on.

In addition to the above uses, basalt has another use with good application prospects, that is, finely ground basalt into stone powder, which can be used as a mixture of cement instead of clay, which can increase cement production, shorten setting time, improve cement performance, and enhance cement flexural resistance Compressive strength, and due to the low melting point of basalt rock powder, the firing temperature can be reduced by 70~100°C during cement calcination, saving coal. The activity of basalt rock powder is equivalent to that of volcanic ash, slag, obsidian, etc. It can produce both ordinary portland cement and volcanic ash portland cement.

Cast basalt wear-resistant aggregates are widely used in the manufacture of various wear-resistant materials, such as wear-resistant floors, linings for wear-resistant pipes, wear-resistant coatings, etc. In the industrial field, they are employed to enhance the wear resistance and service life of materials.

The Basalt Fiber Power is also named as The Basalt Grated Fiber;

Cast Basalt Powder, also known as basalt powder or greenstone powder, is primarily derived from high-quality raw materials, notably crystallized cast basalt. Through crushing and ball milling, it forms a fine, light gray powder renowned for its excellent acid and alkali resistance. The main components are silicon dioxide and aluminum oxide, with trace amounts of other oxides, iron oxide, calcium oxide, titanium dioxide, etc. Cast basalt powder can be formulated into acid-resistant (alkali) mortar, surpassing the corrosion resistance of acid-resistant cement by over ten times. Ranging from 120 mesh to 300 mesh, it showcases superior performance.

Scientific blending is crucial when mixing cast basalt powder with other materials. For formulating acid-resistant refractory castables, common materials and their acid resistance (measured by weight, %) are: cast basalt 98%, silica stone greater than 97%, clay clinker 92%–97%, talc 92%–96%, and andesite greater than 94%. The choice depends on usage conditions. It's essential to note that the use of silica requires caution due to crystalline changes during heating, causing volume variations (expansion). Hence, waste silica brick materials are used to replace some silica raw materials as aggregates. The powder for this castable mainly includes silica powder, cast basalt powder, porcelain powder, high-silica clay clinker powder, with cast basalt powder being a prevalent acid-resistant powder.

High Wear Resistance: The wear resistance of cast basalt aggregate and powder surpasses ordinary steel and even manganese steel.

Corrosion Resistance: Materials composed of cast basalt aggregates, sands, and powder exhibit robust corrosion resistance.

Uniform Particle Size: Cast basalt powder offers a uniform and fine texture, facilitating consistent mixing for production needs.

Low Water Absorption: Cast basalt aggregates, sands, and powder have an almost zero water absorption rate.

Cast basalt wear-resistant aggregates are widely used in the manufacture of various wear-resistant materials, such as wear-resistant floors, linings for wear-resistant pipes, wear-resistant coatings, etc. In the industrial field, they are employed to enhance the wear resistance and service life of materials.

The chopped basalt fiber usually chopped to 400mesh,the diameter of the fiber is between 9-18μm, the length is between 30-50μm. The highest temperature could reach to 1000℃.

The wear resistance performance of the basalt fiber powder is very nice, it is widely used in friction material, such as the brake plate, the polishing wheels, the grinding wheel, the friction plate, the wear resistant pipe, the wear resistant bearing etc.

The basalt fiber powder(the basalt fiber) is also the comprehensive optimal substitute product of the asbestos, the corrosion resistance, the wear resistance, the high temperature resistance and low temperature resistance properties are higher than asbestos, it is low poison, environmental and it is not harm to people, it do not make any pollution in production and using process.

The powder with water form paste cement which is used as an adhesive or filler.

Basalt stone is to break into pieces and then mill. At last it is made of cast basalt. It has high performance of abrasive and corrosion resistance, it can be configured to acid(base)clay. Mixing cast basalt sand and cast basalt hybrid can be made of corrosion-resistant concrete. It has good wear resistance and high mechanical strength. Based on customers' need, casting basalt powders can produce various types of clay, such as sodium sillicate clay, central chloride resin clay, furan resin and so on. Cast powder commonly used atandard 80MESH-500MESH.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.