GB 8163 Steel Pipe

Standard steel pipes suitable for various industrial applications.

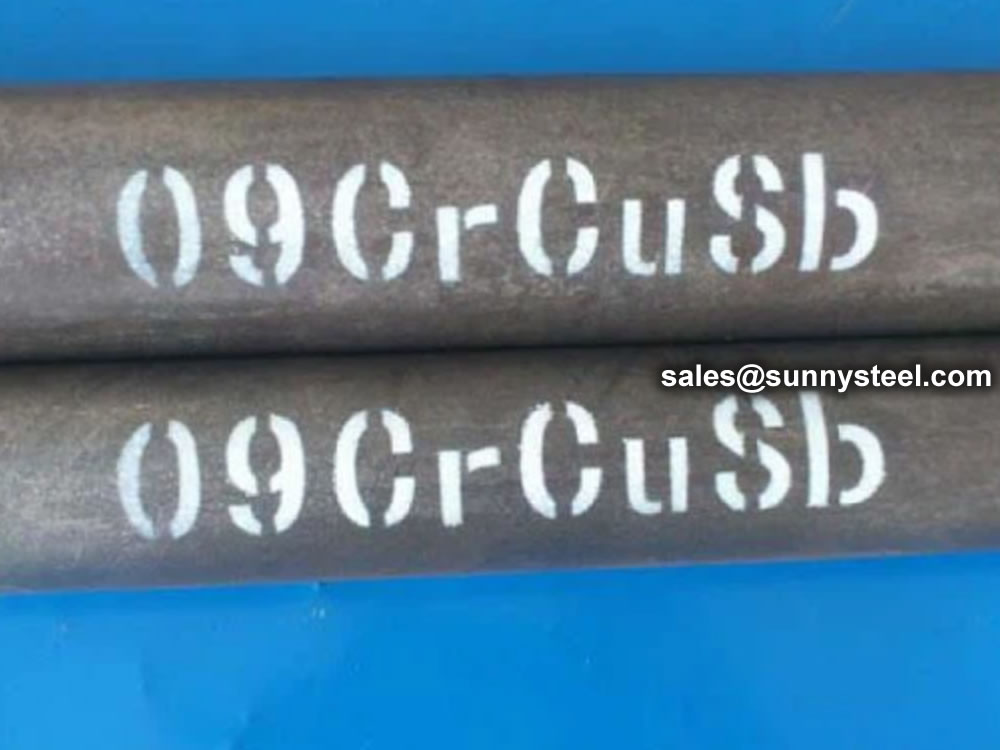

09CrCuSb seamless steel pipe is specifically designed to resist condensation corrosion caused by sulfur-containing flue gas.

09CrCuSb (ND steel) seamless steel pipe is widely used in the manufacture of economizer, air preheater, heat exchanger, and evaporator in the service of high sulfur flue gas equipment, used to resist the dew point corrosion of sulfur flue gas. 09CrCuSb Seamless Tubes also have the ability of chloride ion corrosion resistance. 09CrCuSb Tubes from China are used in power plants and refineries to manufacture coal economizers, air preheaters, heat exchangers, and evaporators, which work in the high sulfur flue gas to resist condensation corrosion of sulfur flue gas. It is the ideal steel for low-temperature dew point corrosion resistance of sulfuric acid at home and abroad. Low-alloy 09CrCuSb Tubes are also widely used.

09CrCuSb (ND) resistant to sulfuric acid low temperature dew point corrosion steel.

ND Steel is a new type of low alloy structural steel, compared with other steel, like low carbon, Corten, CRIA, ND steel has the advantage of excellent corrosion resistance and mechanical property.

The experimental results showed that the corrosion resistance of ND steel in aqueous solution like sulfuric acid, hydrochloric acid and sodium chloride is higher than carbon steel.

The Most prominent feature is the ability of sulfuric dew point corrosion resistance; ND Steel used for manufacturing economizer, heat exchanger, …etc.

09CrCuSb (ND Steel) steel pipe used in power plants & refineries to manufacture economizers, air preheater, heat exchangers & evaporators that work in high -sulfur flue gas to protect against sulfur- containing flue gas condensation.

The specific chemical composition of 09CrCuSb steel may vary slightly depending on the manufacturing standards and requirements. It typically contains elements such as carbon (C), silicon (Si), manganese (Mn), chromium (Cr), copper (Cu), antimony (Sb), phosphorus (P), and sulfur (S).

| Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | Cr | Cu | Sb | P | S | |

| 09CrCusb | ≤0.10 | 0.20-0.40 | 0.35-0.65 | 0.70-1.20 | 0.25-0.45 | ≤0.10 | ≤0.10 | ≤0.10 |

| Grade | Tenslle Strength(MPa) | Yield Strength(MPa) | Elongation(%) |

| 09CrCuSb | 390-550 | ≥245 | ≥25 |

| Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | P | S | Cr | Cu | Sb | |

| 09CrCuSb | ≤0.12 | 0.20~0.40 | 0.35~0.65 | ≤0.030 | ≤0.020 | 0.70~1.10 | 0.25~0.45 | 0.04~0.10 |

| Steel grade | 09CrCuSb(ND steel) | CRIR(Japan) | 1Cr18Ni9 | Corten | STEN(Japan) | A3(Q235B) |

| Corrosionrate | 7.30 | 13.40 | 21.70 | 63.00 | 27.4 | 103.50 |

| multiple | 1 | 1.84 | 2.97 | 8.63 | 3.75 | 14.11 |

| Specification | Specification |

| 19*2-4mm | 76-114 * 4-10mm |

| 25 * 2-4mm | 133-140 * 6-14mm |

| 32 * 2-5mm | 159-219 * 21-35mm |

| 38-42 * 3-5mm | 273-325 * 7-50mm |

| 51-63 * 3-5mm | 356-630 * 10-20mm |

09CrCuSb (ND steel) steelis developed for coal-fired boilers, oil-fired boilers; heat exchangers for electric furnaces, pipes, chimneys, boiler air preheaters, economizers, heat exchangers, condensing coolers, evaporators, etc. Hot-rolled steel sheets and steel pipes with excellent resistance to sulfuric acid dew corrosion. Its superior resistance to sulfuric acid dew point corrosion and very high cost performance is the best material that can completely replace stainless steel and surpass stainless steel (in terms of sulfuric acid dew point corrosion resistance). ND steel has great economic significance, in line with today's high efficiency, longevity and energy saving. "Green" concepts such as environmental protection and national development policy orientation.

09CrCuSb, also known as ND steel, is a seamless steel pipe material designed specifically for resistance to sulfuric acid low-temperature dew point corrosion. This type of steel is widely used in equipment such as coal-fired boilers, oil-fired boilers, economizers, air preheaters, heat exchangers, and evaporators, which operate in environments with high sulfur-containing gases due to its excellent corrosion resistance.

The corrosion resistance of ND steel is mainly attributed to the addition of copper (Cu) and antimony (Sb) in its chemical composition, which enhances the steel's ability to withstand sulfuric acid environments.

According to various sources, the chemical composition of ND steel includes carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), chromium (Cr), copper (Cu), and antimony (Sb). The specific content range of these elements varies in different standards, but typically, the chromium (Cr) content ranges from 0.70-1.20%, copper (Cu) content is between 0.25-0.45%, and antimony (Sb) content is within 0.04-0.10%.

The mechanical properties of ND steel are also outstanding, with good tensile strength and yield strength, as well as a high elongation rate. In a 70°C, 50% sulfuric acid solution, the corrosion rate of ND steel is significantly lower than that of carbon steel and other steel types, demonstrating its superior corrosion resistance.

Additionally, ND steel has good weldability, with the mechanical properties of the weld being almost identical to that of the base material, making it more convenient to process ND steel in practical applications.

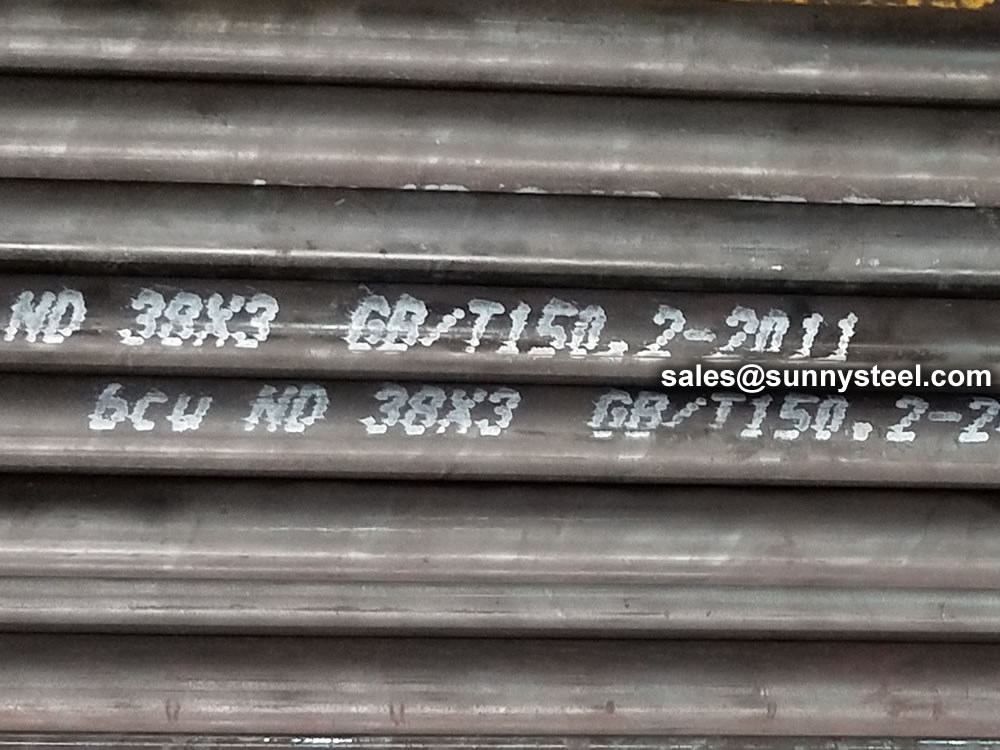

09CrCuSb seamless steel pipes are produced according to various standards, such as GB/T150.2-2011. These standards specify the technical requirements for the manufacturing process, chemical composition, mechanical properties, and dimensions of the pipes.

ND steel, 09CrCuSb steel, is the most ideal steel for “sulfuric acid resistant low temperature dew point corrosion” at home and abroad. ND steel is widely used in the manufacture of economizers, air preheaters, heat exchangers and in high sulfur flue gas. Equipment such as evaporators, used to resist corrosion of sulfur-containing flue gas dew point. ND steel also has the ability to resist chloride ion corrosion. The main reference index of ND steel pipe (soaked in 50% H2SO4 solution at 70 °C for 24 hours) is higher than that of carbon steel and stainless steel.

09CrCuSb бесшовные стальные трубы, также называемые сталью ND, широко используются на электростанциях и нефтеперерабатывающих заводах для изготовления экономайзеров, воздухоподогревателей и теплообменников, работающих в высокосернистых дымовых газах. Испаритель и испаритель используются для защиты от конденсации и коррозии. серосодержащих дымовых газов.

09CrCuSb seamless steel pipes are widely used in various applications, including the manufacturing of economizers, air heat preheaters, heat exchangers, evaporators, and other equipment operating in high-sulfur environments.

ND Steel, known for its excellent resistance to sulfuric acid corrosion at low temperatures, is extensively utilized in the manufacturing of equipment that operates in environments with high sulfur-containing gases. This includes components such as economizers, air preheaters, heat exchangers, and evaporators that are subjected to sulfur-bearing flue gas condensation corrosion.

The widespread use of ND Steel in power plants and refineries is due to its ability to withstand the corrosive effects of sulfur-laden flue gases, which are common in these industrial settings. The materials are particularly effective in the following applications:

By leveraging the properties of ND Steel, these critical pieces of equipment are better equipped to handle the corrosive challenges presented by sulfurous environments, thereby enhancing their longevity and operational efficiency.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.