ASTM A192 Fin Tube

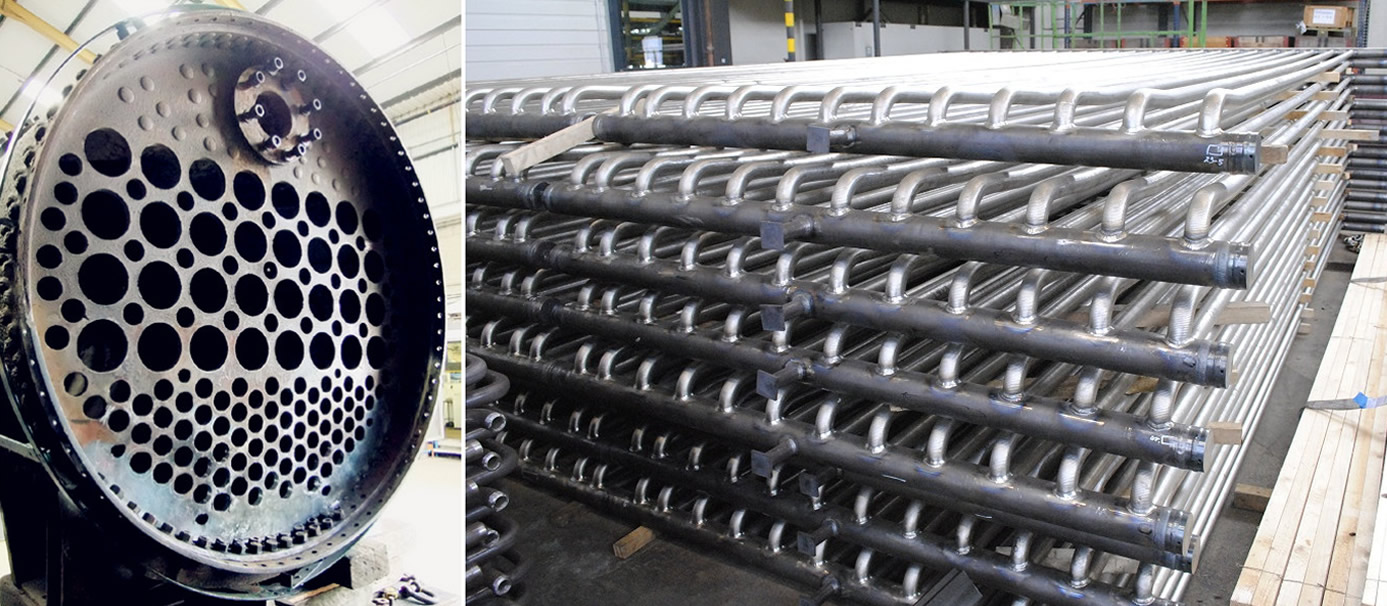

ASTM A192/ASME SA192 finned tubes designed for efficient heat exchange in various applications.

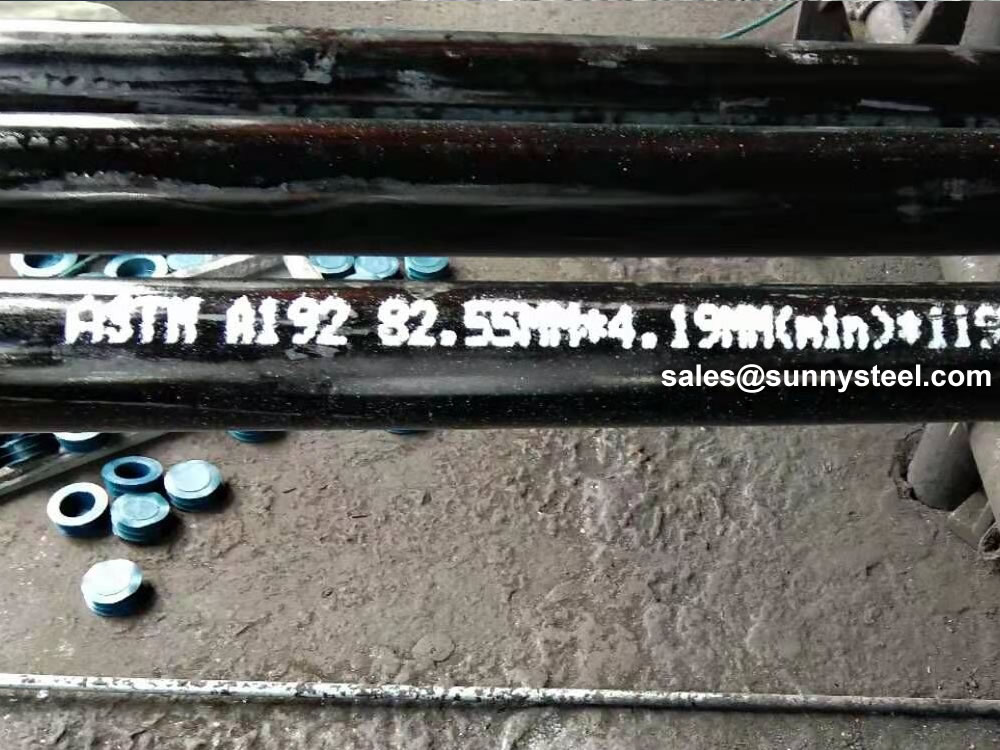

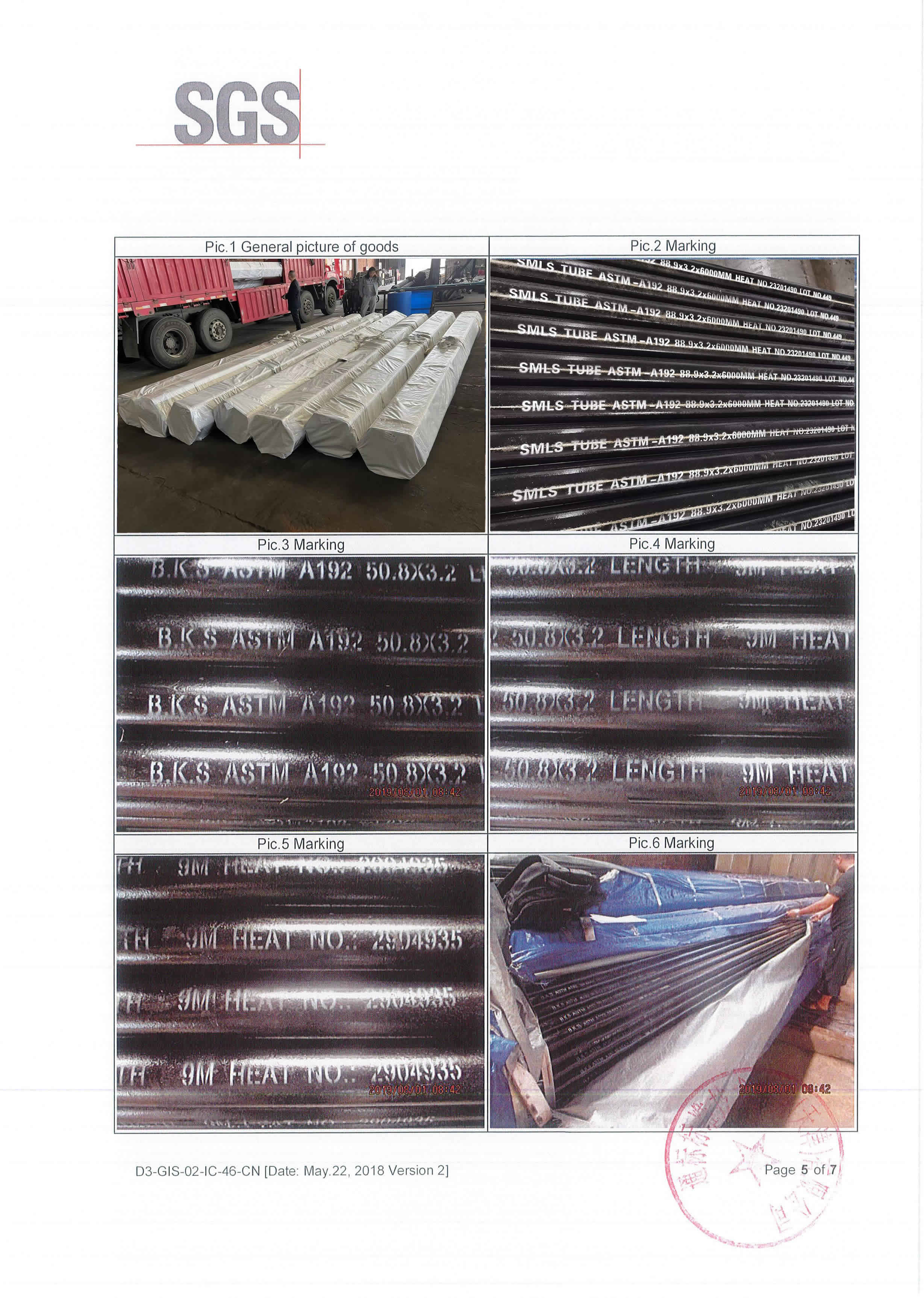

ASTM A192/A192M Standard Specification for Seamless Carbon Steel Boiler Tubes for High-Pressure Service.

Download PDFASTM A192/A192M is a standard specification established by ASTM International for seamless carbon steel boiler tubes. This specification is primarily designed for high-pressure service, particularly in applications where tubes are subjected to high temperatures and pressures.

ASTM A192/A192M is a significant standard that plays a crucial role in the field of materials.

This standard specifically pertains to seamless carbon steel boiler tubes for high-pressure service. It sets strict guidelines for the manufacturing process, material composition, and performance characteristics of these tubes.

Tubes adhering to ASTM A192/A192M are designed to withstand extreme temperatures and pressures, making them indispensable in boiler applications where safety and reliability are of paramount importance.

The precise specifications within the standard ensure consistent quality, allowing for efficient heat transfer and long-term durability. This helps to minimize the risk of failures and maintenance issues in critical systems.

Manufacturers and end-users rely on ASTM A192/A192M to guarantee the suitability and performance of the boiler tubes, contributing to the overall efficiency and safety of industrial operations.

ASTM A192/A192M guide covers standard specifications for minimum-wall-thickness, seamless carbon steel boiler and superheater tubes for high-pressure service. The steel shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, and silicon. The tubes shall have a hardness number not exceeding a specific value. The following mechanical tests shall be conducted, namely: flattening test; flaring test; hardness test; and hydrostatic test.

ASTM A192 is a standard for seamless carbon steel boiler and superheater tubes with minimum wall thickness for high-pressure applications. The standard is issued under the fixed designation A 192/A 192M. It is under the jurisdiction of ASTM Committee A01 on Steel.

ASTM A192 is generally used for high-pressure boilers with a working pressure that does not exceed 9.8Mpa. The tubes are available in hot rolled and cold drawn delivery states.

ASTM A192 Seamless Steel Tube is applied as minimum-wall-thickness, seamless carbon steel boiler and superheater tubes for high-pressure service.

1.1 This specification2 covers minimum-wall-thickness, seamless carbon steel boiler and superheater tubes for high-pressure service.

1.2 The tubing sizes and thicknesses usually furnished to this specification are 1/2 in. to 7 in. [12.7 to 177.8 mm] outside diameter and 0.085 to 1.000 in. [2.2 to 25.4 mm], inclusive, in minimum wall thickness. Tubing having other dimensions may be furnished, provided such tubes comply with all other requirements of this specification.

1.3 Mechanical property requirements do not apply to tubing smaller than 1/8 in. [3.2 mm] inside diameter or 0.015 in. [0.4 mm] thickness.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

| Element | Content, % |

|---|---|

| C | 0.06~0.18 |

| Mn | 0.27~0.63 |

| P | ≤0.035 |

| S | ≤0.035 |

| Si | ≤0.25 |

| Mechanical Property Requirements | Data |

|---|---|

| T.S. min ksi [MPa] |

47 [325] |

| Y.S. min ksi [MPa] |

26 [180] |

| El. in 2" min, % |

35 |

| Brinell Hardness max. HBW |

137 |

| Rockwell Hardness, max. HRBW |

77 |

The tensile strength and yield strength of the ASTM A192/ ASME SA-192 tube are 325 MPa and 180 MPa at room temperature, respectively.

*T.S.: tensile strength; *Y.S.: yield strength; *El.: elongation.

*The Brinell Hardness number applies to ASTM A192 tubes 0.200″ [5.1 mm] and over in wall thickness.

*The Rockwell Hardness number applies to ASTM A192 tubes less than 0.200″ [5.1 mm] in wall thickness.

*Mechanical properties don’t apply to tubing smaller than 1/8″ [3.2 mm] inside diameter or 0.015″ [0.4 mm] thickness.

Flattening test, flaring test, hardness test, hydrostatic test, and tension test.

ASTM A 192 boiler tube equivalent EN 10216-2, DIN 17175, BS 3059 Part II, NF A 49-213, NBR 5594 ASTM (American Society for Testing Materials standard) A192 and ASME (American Society of Mechanical Engineers standards) SA192. Equivalent Materials 1010, St35.8, 360. FASTWELL has standard specifications for minimum-wall-thickness, seamless carbon steel boiler and super heater tubes for high-pressure service.

| Grade | ASTM A192 / ASME SA192 | |

|---|---|---|

| UNS No | K01201 | |

| Old British | BS | CFS 320 |

| German | No | 17175 |

| Number | 1.0305 | |

| Belgian | 837 | |

| Japanese JIS | D3563 / G3461 | |

| French | A49-213 | |

| Italian | 5462 | |

Maximum working pressure of ASTM A192 Tube at temperature 400°F, The dimensions - outside pipe diameters and wall thicknesses are according ANSI B36.10.

| Maximum Allowable Pressure (psi) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | Outside Diameter | Schedule | ||||||||||||

| (in) | (in) | 10 | 20 | 30 | STD | 40 | 60 | XS | 80 | 100 | 120 | 140 | 160 | XXS |

| 1/4 | 0.54 | 7985 | 7985 | 10798 | 10798 | |||||||||

| 3/8 | 0.675 | 6606 | 6606 | 9147 | 9147 | |||||||||

| 1/2 | 0.84 | 6358 | 6358 | 8575 | 8575 | 10908 | 17150 | |||||||

| 3/4 | 1.05 | 5273 | 5273 | 7187 | 7187 | 10220 | 14373 | |||||||

| 1 | 1.315 | 4956 | 4956 | 6670 | 6670 | 9316 | 13340 | |||||||

| 1 1/4 | 1.66 | 4133 | 4133 | 5638 | 5638 | 7380 | 11276 | |||||||

| 1 1/2 | 1.9 | 3739 | 3739 | 5158 | 5158 | 7247 | 10316 | |||||||

| 2 | 2.375 | 3177 | 3177 | 4498 | 4498 | 7097 | 8995 | |||||||

| 2 1/2 | 2.875 | 3460 | 3460 | 4704 | 4704 | 6391 | 9408 | |||||||

| 3 | 3.5 | 3024 | 3024 | 4200 | 4200 | 6132 | 8400 | |||||||

| 3 1/2 | 4 | 2769 | 2769 | 3896 | 3896 | |||||||||

| 4 | 4.5 | 2581 | 2581 | 3670 | 3670 | 4769 | 5782 | 7339 | ||||||

| 5 | 5.563 | 2273 | 2273 | 3303 | 3303 | 4404 | 5505 | 6606 | ||||||

| 6 | 6.625 | 2071 | 2071 | 3195 | 3195 | 4157 | 5318 | 6390 | ||||||

| 8 | 8.625 | 1420 | 1574 | 1829 | 1829 | 2307 | 2841 | 2841 | 3375 | 4085 | 4613 | 5147 | 4971 | |

| 10 | 10.75 | 1140 | 1399 | 1664 | 1664 | 2279 | 2279 | 2708 | 3277 | 3847 | 4558 | 5128 | 4558 | |

| 12 | 12.75 | 961 | 1268 | 1441 | 1560 | 2160 | 1922 | 2644 | 3244 | 3843 | 4324 | 5042 | 3843 | |

| 14 | 14 | 875 | 1092 | 1313 | 1313 | 1533 | 2079 | 1750 | 2625 | 3283 | 3829 | 4375 | 4921 | |

| 16 | 16 | 766 | 956 | 1148 | 1148 | 1531 | 2009 | 1531 | 2585 | 3157 | 3733 | 4404 | 4882 | |

| 18 | 18 | 681 | 849 | 1192 | 1021 | 1530 | 2042 | 1361 | 2553 | 3147 | 3743 | 4252 | 4848 | |

| 20 | 20 | 613 | 919 | 1225 | 919 | 1455 | 1989 | 1225 | 2526 | 3138 | 3675 | 4288 | 4824 | |

| 22 | 22 | 557 | 835 | 1114 | 835 | 1949 | 1114 | 2506 | 3063 | 3619 | 4176 | 4733 | ||

| 24 | 24 | 510 | 766 | 1147 | 766 | 1405 | 1978 | 1021 | 2489 | 3126 | 3700 | 4210 | 4786 | |

| 30 | 30 | 510 | 817 | 1021 | 613 | 817 | ||||||||

| 32 | 32 | 478 | 766 | 957 | 574 | 1054 | ||||||||

| 34 | 34 | 450 | 721 | 901 | 540 | 992 | ||||||||

| 36 | 36 | 425 | 681 | 851 | 510 | 1021 | ||||||||

| 42 | 42 | 583 | 729 | 438 | 875 | |||||||||

The ASTM A192/ASME SA192 standard is applicable to seamless carbon steel pipes used for boilers and superheaters in high-pressure environments, with a focus on meeting the minimum wall thickness necessary for these applications.

ASTM A 192 boiler tube equivalent EN 10216-2, DIN 17175, BS 3059 Part II, NF A 49-213, NBR 5594 ASTM (American Society for Testing Materials standard) A192 and ASME (American Society of Mechanical Engineers standards) SA192. Equivalent Materials 1010, St35.

American Standard A192/SA192 Seamless Carbon Steel Boiler and Superheater Tubes for High Pressure Minimum Wall Thicknesses

Affordable High-Pressure Boiler Tube ASTM A192 /SA192 Carbon Steel Seamless Pipe

Our ASTM A192/A192M are widely used in various industries due to their excellent properties and performance. Some of the key industries and applications where ASTM A192 tubes find extensive use include:

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.