Nipo Flange

Nipoflange is a connection that has a flange on one side and a Nipolet on the other side.

An anchor flange is a device to restrain pipe movement in a piping system,it looks like a weld neck flange but has two hubs on the both sides to weld with the pipes,but there is no bolt bores on the anchor flanges.

Quality Standard for Anchor Flanges

High quality Anchor Flanges all made and controlled to the relevant standards such as: ASME, ASTM, BS and DIN/WERKSTOFFE.

Sizes for Anchor Flanges

Welded into the line and encased in concrete, they immobilize the pipe at predetermined locations and transfer built-up stresses to external structures. For example, in cross-county pipelines end forces of considerable magnitude are generated by internal pressure and temperature changes. A 24″ O.D. x 0.594″ wall pipe in a pipeline operating at 1100 psi and subjected to a 90° rise in metal temperature, for example, will develop total thrust of 1,000,000 lbs.

Unless these forces are properly controlled, they can damage pumps, valves and other close-tolerance equipment. Anchor Flange may be used to secure subsea piping and risers to platform structures.

The Anchor flange is designed for immobilization of high pressure pipe lines.

The Anchor flange is a one-piece combination reducer and welding neck flange designed expressly for effecting pipe size increases at flanged connections to pumps, valves, compressors and other equipment. It provides a more compact, more efficient and frequently a more economical means than is permitted by the conventional two-piece combination of a concentric reducer and welding neck flange.

The following information must be provided while ordering an anchor flange.

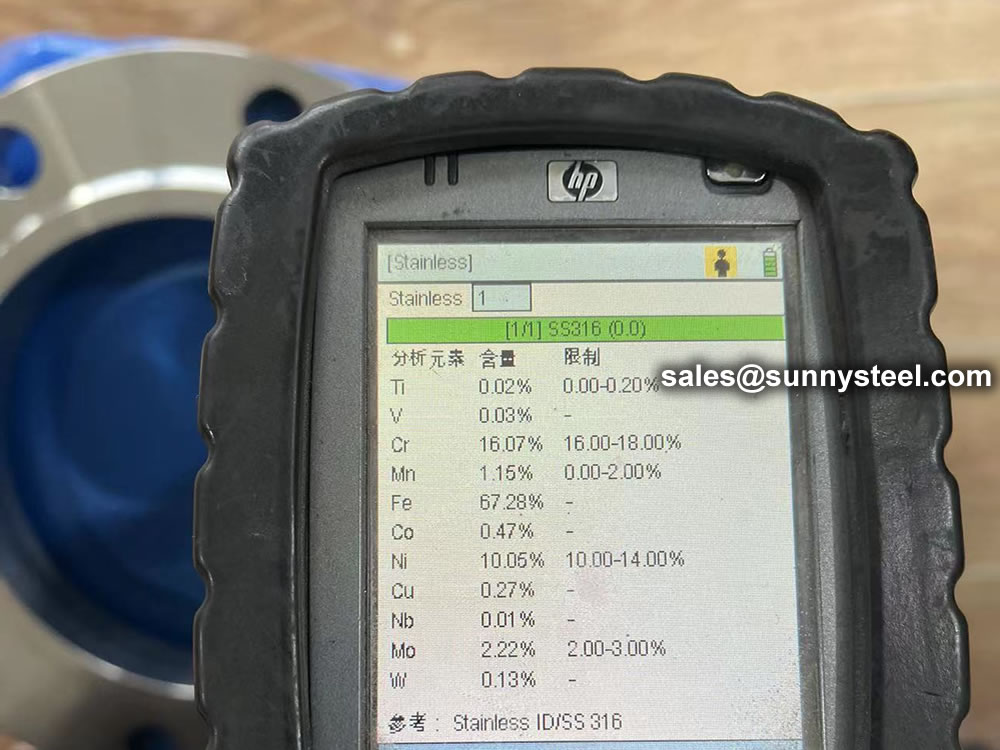

The anchor flange is used to restrain and fasten the piping system,so the material of anchor flange should be in high strength.In our flange factory,the most common anchor flange material is SA105,ASTM A694 F52,F60 and F65 material is also recommended if necessary.If you have any question and need about the anchor flange,welcome to contact us for further information.

Pipe flanges are manufactured in all the different materials like stainless steel, cast iron, aluminium, brass, bronze, plastic etc. but the most used material is forged carbon steel and have machined surfaces.

Flanges are welded to pipe and equipment nozzle. Accordingly, it is manufactured from the following materials;

The list of materials used in manufacturing is covered in ASME B16.5 & B16.47.

Commonly used Forged material grads are

| Material | Fittings | Flanges | Valves | Bolts & Nuts |

|---|---|---|---|---|

| Carbon Steel | A234 Gr WPA | A105 | A216 Gr WCB | A193 Gr B7 A194 Gr 2H |

| A234 Gr WPB | A105 | A216 Gr WCB | ||

| A234 Gr WPC | A105 | A216 Gr WCB | ||

| Carbon Steel Alloy High-Temp |

A234 Gr WP1 | A182 Gr F1 | A217 Gr WC1 | A193 Gr B7 A194 Gr 2H |

| A234 Gr WP11 | A182 Gr F11 | A217 Gr WC6 | ||

| A234 Gr WP12 | A182 Gr F12 | A217 Gr WC6 | ||

| A234 Gr WP22 | A182 Gr F22 | A217 Gr WC9 | ||

| A234 Gr WP5 | A182 Gr F5 | A217 Gr C5 | ||

| A234 Gr WP9 | A182 Gr F9 | A217 Gr C12 | ||

| Carbon Steel Alloy Low-Temp |

A420 Gr WPL6 | A350 Gr LF2 | A352 Gr LCB | A320 Gr L7 A194 Gr 7 |

| A420 Gr WPL3 | A350 Gr LF3 | A352 Gr LC3 | ||

| Austenitic Stainless Steel | A403 Gr WP304 | A182 Gr F304 | A182 Gr F304 | A193 Gr B8 A194 Gr 8 |

| A403 Gr WP316 | A182 Gr F316 | A182 Gr F316 | ||

| A403 Gr WP321 | A182 Gr F321 | A182 Gr F321 | ||

| A403 Gr WP347 | A182 Gr F347 | A182 Gr F347 |

ASTM standards define the specific manufacturing process of the material and determine the exact chemical composition of pipes, fittings and flanges, through percentages of the permitted quantities of carbon, magnesium, nickel, etc., and are indicated by "Grade".

The usual materials of flanges include stainless steel, carbon steel, aluminum and plastic. The choice of the material largely depends on the purpose of the flange. For example, stainless steel is more durable and is necessary for heavy use. On the other hand, plastic is more feasible for use in the home because of its reasonable price and easy installation. The materials used for flanges are under the designation of the American Society of Mechanical Engineers.

The most common materials for pipe flanges (forged grades) are: ASTM A105 (carbon steel high temperature to match A53/A106/API 5L pipes), A350 Grades LF1/2/3 (carbon steel low temperature to match A333 pipes), A694 Grades F42 to F80 (high yield carbon steel to match API 5L pipe grades), ASTM A182 Grades F5 to F91 (alloy steel flanges to match A335 pipes), A182 Grade F304/316 (stainless steel flanges to match A312 SS pipes), A182 Gr. F44/F51/F53/F55 (duplex and super duplex to match A790/A928 pipes) and various nickel alloy grades (Inconel, Incoloy, Hastelloy, Monel).

The material qualities for these flanges are defined in the ASTM standards.

For example, a carbon steel pipe can be identified with Grade A or B, a stainless-steel pipe with Grade TP304 or Grade TP321, a carbon steel fitting with Grade WPB etc.

Pipe Flange Standards mainly include three systems in the world, ANSI/ASME flange system(American), DIN flange system(European system), JIS flange system, other system made according to this three systems, like GB flange standard, which mainly made according to ANSI/ASME and DIN flange standard, Duwa Piping supplies those flanges with top quality and soonest delivery time.

As we know,the steel piping system could move and shake when the liquid flowing through the pipe,especially when the piping system is turning in some places,the liquid will push the turning in the direction of liquids flowing. Another application of the anchor flange,there may bring expansion movements when temperature is changing in the piping system. Then an anchor flange is installed to combat the axial movement in the pipeline. The anchor flange is commonly secured into a concrete foundation. Besides preventing the axial movement,the anchor flange is also installed when the pipeline crossing from a bridge or river. Among this large distance,the pipe with huge liquid has the tendency to sag,if we use the anchor flange on the both sections of the pipeline,it will secure the position of the pipe.

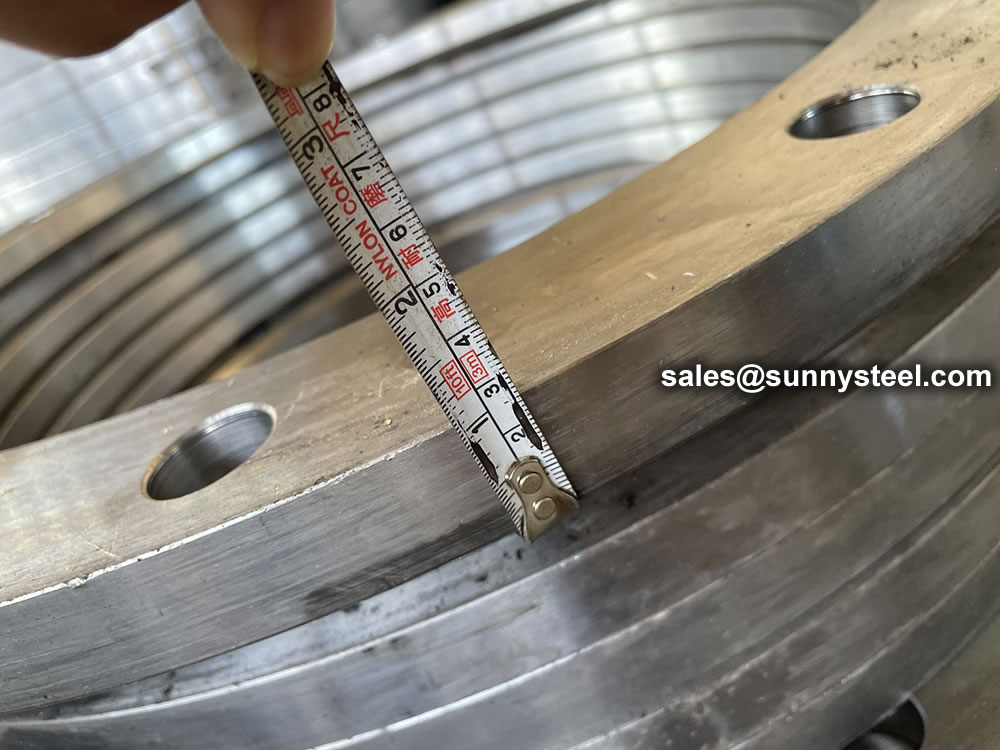

When we install a anchor flange in the chosen position solidly in a pipeline,we should weld the anchor flange with the two pipes first,then pour the concrete around the anchor flanges and the pipeline,the anchor flange should be sealed in the cement concrete.The anchor flange neck thickness and diameter should be same with the pipe dimensions for welding.

The most frequently asked questions regarding flanges and flange fittings have to do with how flanges fit on specific steel tube and steel pipe ends.

Flanges have flat or flush surfaces that are vertical to the pipe to which they are attached. The attachment process involves mechanically joining two or more faces using bolts, adhesives, collars, or welds. Due to the attachment requirements, a flange must fit the equipment or pipe that it’s designed. That’s why it’s necessary to check all the possible specifications and dimensions to ascertain that it’s of the right size, type, and material.

Pipe flanges, gaskets, and bolts are the three parts that comprise a flanged connection. Gaskets and bolts are typically made of the same flange materials or a material approved for the pipe components. Each component comes in various materials that suit specific applications and must be matched correctly for proper functioning. The gaskets come in two conventional types: full-face gaskets and ring gaskets. Full-face gaskets have the bolt holes visible and pair up with raised-face gaskets. Ring gaskets tend to be smaller rings minus the bolt holes and pair up with flat-faced flanges. Securing the flange components requires matching the surfaces evenly and plumb, adjusting as needed for a uniform fit. Once all surfaces match, bring the flanges together and secure at least two of the bolts. Refine the alignment, so the remaining bolt holes match and their corresponding bolts are tightly secured.

Properly sizing a flange for pipe use depends not only on the type of flange but its compatible piping. The pipe must slip into the flange’s inside diameter easily and securely, and the outside diameter should cover wall holes. Once you determine the specific flange type and material you need for the job, you’ll need to take several measurements. The four measurements you’ll need are the inside diameter, outside diameter, bolt hole count, and bolt hole center. You’ll need to align each of these measurements from opposing bolt holes to get the most accurate readings. Take all measurements from edge to edge and try to get as precise as possible to match the correct product. Round up bolt diameter to the next half or whole step since bolts measure half or whole inches. Once you have all four measurements, check them against the manufacturer’s table to find the correct flange. Most manufacturers list these specifications on their websites for easy reference.

Before dispatching from manufacture each flange is inspected to ensure quality. During an inspection you have to check the following;

ASME B16.5 and B16.47 standards cover permissible tolerances for inspection.

Flanges are used to connect pipes or other equipment components in various industries, and they come in a variety of materials and sizes. Flange material standards are developed by standard-setting organizations and describe the properties and characteristics of different materials that can be used to make flanges. Some examples of commonly used flange material standards include:

The choice of flange material standard will depend on various factors such as the application, the environment, the fluid being transported, and the required performance characteristics. For example, high-pressure applications may require flanges made from materials with high strength and durability, while corrosive environments may require flanges made from materials with good resistance to corrosion.

There are many ways to connect flanges, including threading, welding or bolting. The threaded flange is best for low pressure or smaller pipelines because it can maintain its seal. When your pipeline is larger or high pressure, then the welded flange is preferable. A boiler room is one place where welded blind flanges might be used, due to the high pressure involved.

Flanged joints: flanges, bolts and nuts and gaskets

A flange is a external rib at the end of pipes, valves and other flow devices to assemble them.

Dimensions of the flanges are up to specific Standards : DIN, ANSI, AS, BS, JIS

A flanged connection requires two flanges (the “main” and the “companion”), a set of bolts and nuts (whose number depends on the flange diameter and class) and two sealing gaskets. Flanged connections have to be executed and supervised by trained personnel, as the quality of the joint has a critical impact on the performance of the piping system / pipeline (the standard TSE – TS EN 1591 Part 1-4, “Flanges and their joints”, defines a number of requirements for the execution of proper flanged connections). Whereas all elements of the joint are critical, experience shows most leaks are originated by the improper installation of the sealing elements, i.e. the gaskets.

The typical pipe to flange connections are welded or threaded. Welded flanges are used for pipelines and piping systems with high pressures and temperatures, and with diameters above 2 inches.

Threaded connections are instead used for installations of smaller diameter and not subject to severe mechanical forces such as expansion, vibration, contraction, oscillation (forces that would crack the threaded joint). In all these critical cases, butt weld connections are recommended.

Steel flanges must be packed with seaworthy packing method then delivery to customers, usually the packing way include wooden box, wooden pallet, iron & steel cage, iron & steel pallet etc.

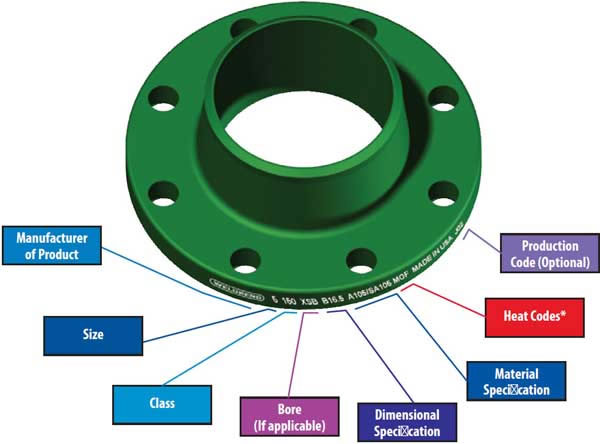

Flange markings are governed by ANSI ASME codes. Flange marking includes;

ASME B16.5 and B16.47 standards cover permissible tolerances for inspection.

Because of the normal wooden boxes or wooden pallets have to do fumigation treatment, we usually use plywood pallet or plywood case or box to pack steel flanges without fumigation treatment.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.