904L stainless steel consists of chromium, nickel, molybdenum and copper contents, these elements give type 904L stainless steel excellent properties to resist corrosion in dilute sulfuric acid because of addition of copper, 904L commonly is used in high pressure and corrosion environment where 316L and 317L perform poorly.

904L has high nickel composition with low carbon content, copper alloy adding improve its resistance to corrosion, the “L” in 904L stands for low carbon, it is typical Super Austenitic stainless steel, equivalent grades are DIN 1.4539 and UNS N08904, 904L has better properties than other austenitic stainless steels.

904L is a high-alloy austenitic stainless steel known for its exceptional resistance to corrosion, particularly in harsh environments involving sulfuric acid. It combines high chromium content with nickel, molybdenum, and copper, making it one of the best choices for combating both pitting and general corrosion.

| Grade | Ni | Cr | Mo | Cu | C | Mn | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 904L | 23 – 28 | 19 – 23 | 4 -5 | 1 – 2 | 0.02 | 2 | 1 | 0.045 | 0.035 | Balance |

| Grade | Tensile Strength, Min | Yeild Strength, Min | Elognation | Hardness |

|---|---|---|---|---|

| 904L | 490 Mpa | 215 Mpa | 35% | 90 HRB Max |

| Grade | Density (Kg/M3) |

Elastic Modulus (GPa) |

Mean Co-Eff Of Thermal Expansion (Μm/M/°C) |

Thermal Conductivity (W/M.K) |

Specific Heat 0-100°C (J/Kg.K) |

Elec Resistivity (NΩ.M) |

|||

|---|---|---|---|---|---|---|---|---|---|

| 0-100°C | 0-315°C | 0-538°C | At 20°C | At 500°C | |||||

| 904L | 7900 | 190 | 15 | – | – | 11.5 | – | 500 | 952 |

904L stainless steel price is expensive, due to high amount of molybdenum and nickel content, that leads to grade 904L is replaced by low cost grades, such as 316L, 317L, 2205, 6Mo and super duplex grades.

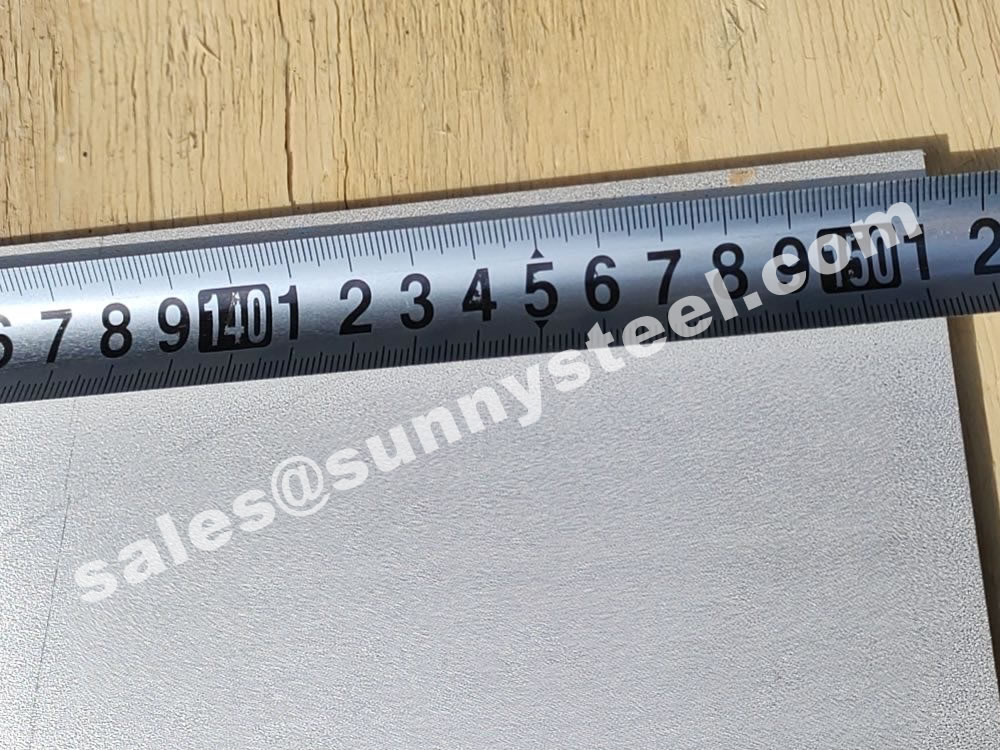

904L stainless steel sheet is a type of superaustenitic stainless steel that is designed for moderate to high corrosion resistance in a wide range of environments. It is known for its excellent resistance to reducing acids like sulphuric acid and its ability to withstand chlorides in the environment, which helps prevent pitting and crevice corrosion.

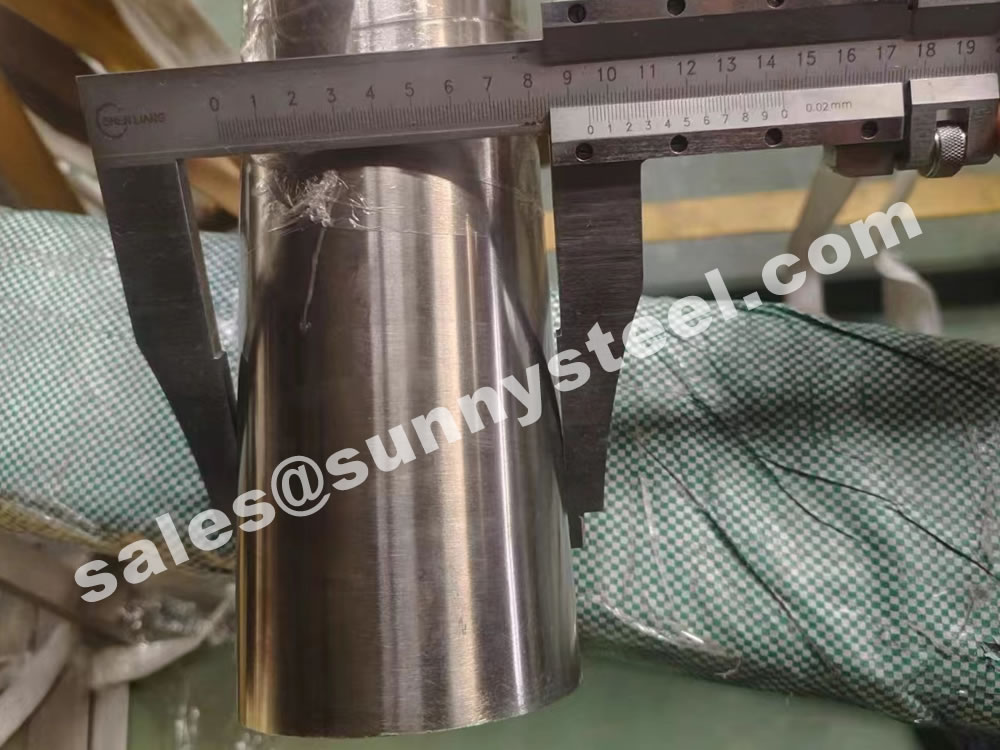

Grade 904L stainless steel bar is a non-stabilized austenitic stainless steel with low carbon content. This high-alloy stainless steel contains copper to enhance its resistance to strong reducing acids, such as sulfuric acid. It also exhibits resistance to stress corrosion cracking and crevice corrosion. Grade 904L bar is non-magnetic and offers excellent formability, toughness, and weldability.

Grade 904L bar contains high amounts of costly ingredients, including molybdenum and nickel. Presently, many applications that once utilized grade 904L bar have shifted to lower-cost duplex stainless steel 2205. The properties of flat rolled products in ASTM B625 are described in the following sections. Note that specifications may not be identical for other products such as bar, tube, and pipe.

904L Round Bar is a multipurpose highly corrosion-resistant stainless steel suitable for your medium to corrosive environments.

904L Round Bar is mostly used in applications where corrosion resistance and high strength are required, such as in marine environments, chemical processing, and oil & gas industries. We also stock various special alloys such as the following: 2205, 2507, 904L, 310, C276 and 17-4PH.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.