Composite wear-resistant steel plate is composed of a low-carbon steel plate and an alloy wear-resistant layer.

The alloy wear-resistant layer is generally 1/3~1/2 of the total thickness. When working, the matrix provides comprehensive properties such as strength, toughness and plasticity against external forces, and the alloy wear-resistant layer provides wear-resistant properties that meet the requirements of specified working conditions.

Composite wear-resistant steel plate, the chemical composition of the alloy wear-resistant layer is 4-5% carbon content, and the chromium content is divided into two grades: 18-30% and 30-40%, and the fraction of Cr7C3 carbides in its metallographic structure by volume reaches 50% Above, the macro hardness is HRC56~62, and the hardness of chromium carbide is HV1400~1800. Because the carbides are distributed perpendicular to the wear direction, the wear resistance is more than doubled compared to cast alloys of the same composition and hardness.

There is a metallurgical bond between the wear-resistant steel plate alloy wear-resistant layer and the substrate. Through special equipment and automatic welding process, the high-hardness self-preserving alloy welding wire is uniformly welded on the substrate, and the number of composite layers is one to two or even multiple layers. During the recombination process, uniform transverse cracks appear due to the different shrinkage rates of the alloys. It is a distinctive feature of wear-resistant steel plates.

The alloy wear-resistant layer is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium and nickel are also added. The carbides in the metallographic structure are distributed in fibers, and the fiber direction is perpendicular to the surface. The microhardness of cemented carbide can reach above HV1700-2000, and the surface hardness can reach HRC58-62. Alloy carbide has strong stability at high temperature, maintains high hardness, and also has good oxidation resistance, and can be used normally within 500 ℃.

The wear-resistant layer has narrow channels (2.5-3.5mm), wide channels (8-12mm), curves (S, W), etc.; it is mainly composed of chromium alloy, and manganese, molybdenum, niobium, nickel, boron are also added. Compared with other alloy components, the carbides in the metallographic structure are distributed in fibers, and the fiber direction is perpendicular to the surface. The carbide content is 40-60%, the microhardness can reach HV1700 or more, and the surface hardness can reach HRC58-62.

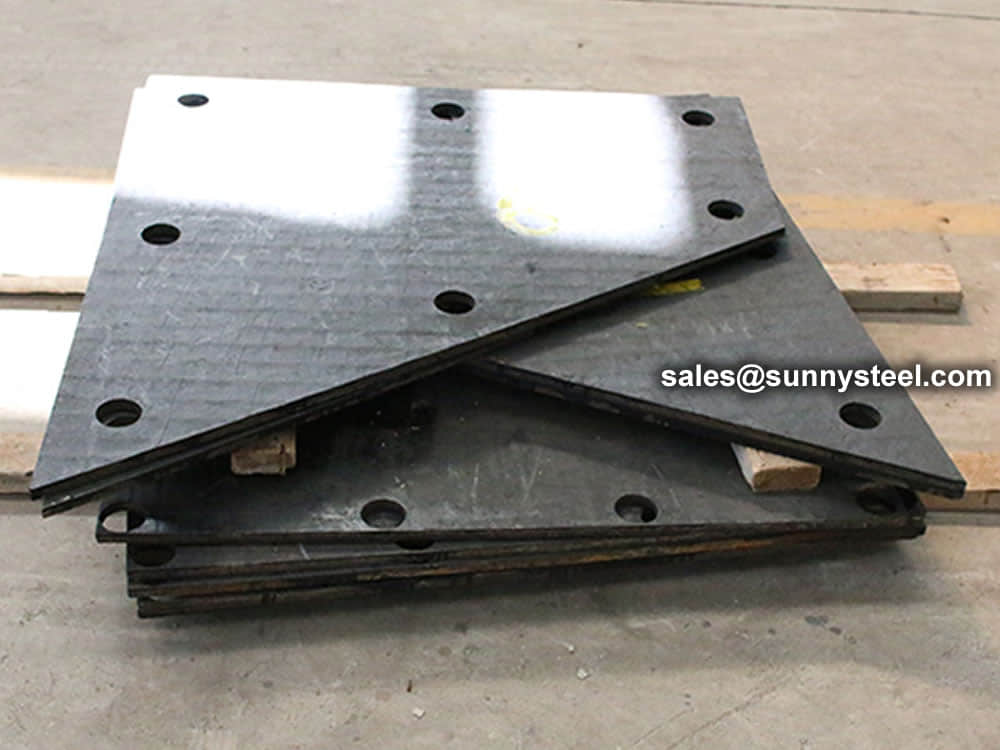

Wear-resistant steel plates are mainly divided into general-purpose, impact-resistant and high-temperature-resistant types; the total thickness of wear-resistant steel plates can reach 5.5 (2.5+3) mm, and the maximum thickness can reach 30 (15+15) mm; wear-resistant steel plates can be Rolled wear-resistant pipes with a minimum diameter of DN200 can be processed into wear-resistant elbows, wear-resistant tees, and wear-resistant reducers. Composite wear-resistant steel plates have been widely used in heavy industry, providing important wear-resistant protection measures for the wear and failure of industrial equipment and workpieces in my country, greatly improving the service life of equipment and workpieces, improving production efficiency for enterprises, reducing Cost of production. made an important contribution. The double-gold composite wear-resistant steel plate adopts the open arc self-protection automatic surfacing process, and a layer of high-hardness, high-wear-resistant high-alloy wear-resistant iron plate is surfacing on the surface of ordinary steel plate or stainless steel. It has bimetallic properties, that is, high wear resistance of the working layer and high plastic toughness of the base layer, which provides convenient mechanical connection and electrode connection conditions for industrial applications, and can realize processing, cutting and mechanical connection such as coiling, welding, and plasma.

We provide wear-resistant composite steel plate, surface hardness can reach 58-63 degrees; Under 500 ° to 600 ° high temperature condition can maintain high wear resistance, tempering hardness reach to HRC63 °. Abrasion resistance is 18 to 22 times of low carbon steel, six to eight times that of stainless steel, high manganese steel, is generally more than 1.5 times high carbon high chromium wear-resistant steel plate.

The backing mild steel plate provides overlay plates with structural integrity, which makes our overlay plates fabricated with zero damage to welding overlay, regardless of the shape and complexity of the structure. Our factory has the capabilities to manufacture and further process such fabrications or to supply formed, read-to-go wear liners, all of which are widely used in mining industry, cement plants, steel mills, power plants, sugar industry, glasses and paper industries, etc.

Cutting

Composite overlay plates could be cut by plasma, waterjet, laser. Plasma cutting is the recommended method for cutting composite plate.

Studs attachment

Composite plate can be fabricated with studs welded to backing of wear plate (M12, M16, M20 and M24).

Drilling

Straight holes and countersunk holes.

Joint welding

Composite wear plate can be welded and assembled into kinds of wear parts.

Chromium carbide composite wear plate is a new type of composite wear-resistant material that is widely used in heavy wear industry such as cement plant, steel mill, mining plant and coal-fired power plant.

It has excellent wear resistance. At present, there are a variety of different brand products on the market, and their wear resistance is between 4-15 times. Therefore, when selecting materials, it is appropriate to consider the wear resistance of the product. As the company adhere to high quality policy, the production of composite steel plate welding molding the whole wear-resistant plate, size can be up to 12 m x 2.2 m = 26.4 m2, area is 6.5 times that of other plate, greatly improves the operational efficiency of china’s major projects and wear-resisting effect, solves the wear resistant steel plate more widespread application of weld, forming many problems, such as hard, at the same time maximize the utilization of plank, reduce the wear and tear. For different size requirements of wear-resistant plate, according to the user’s drawing material, the user plate loss rate is zero.

The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.