92% Ceramic Lined Coal Pipes

Discover our high-abrasion 92% ceramic lined coal steel pipes, designed for durability and performance in harsh environments.

The high alumina ceramic lined bend and elbow are an excellent wear protection that is used in all industries where wear resistance is needed. The high alumina ceramics are installed onto the internal surface of the pipe properly by welding, pasting or inter-locking the system.

Download PDFHigh alumina ceramic lined bends are engineered components designed for applications requiring exceptional wear resistance and corrosion protection. These bends combine the structural strength of steel with the耐磨性和耐化学性的高铝陶瓷lining, offering a durable and reliable solution for demanding industrial processes.

High alumina ceramic lined bends are used in various industries where the transportation of abrasive and corrosive materials is a common requirement. Some specific applications include:

High alumina ceramic lined bends are available in a range of sizes and materials to match the specific requirements of different applications. The ceramic lining is typically applied through processes such as hot isostatic pressing (HIP) or slip casting, ensuring a strong bond with the underlying steel substrate.

These bends are designed for easy installation and can be adapted to fit existing systems. With their durable design, maintenance costs are significantly reduced, making them a cost-effective solution for long-term use.

High alumina ceramic lined bends offer a superior combination of wear resistance, corrosion resistance, and temperature tolerance, making them an excellent choice for industries that require the transportation of abrasive and corrosive materials. Their customizable design and easy installation make them a versatile solution for a wide range of industrial applications.

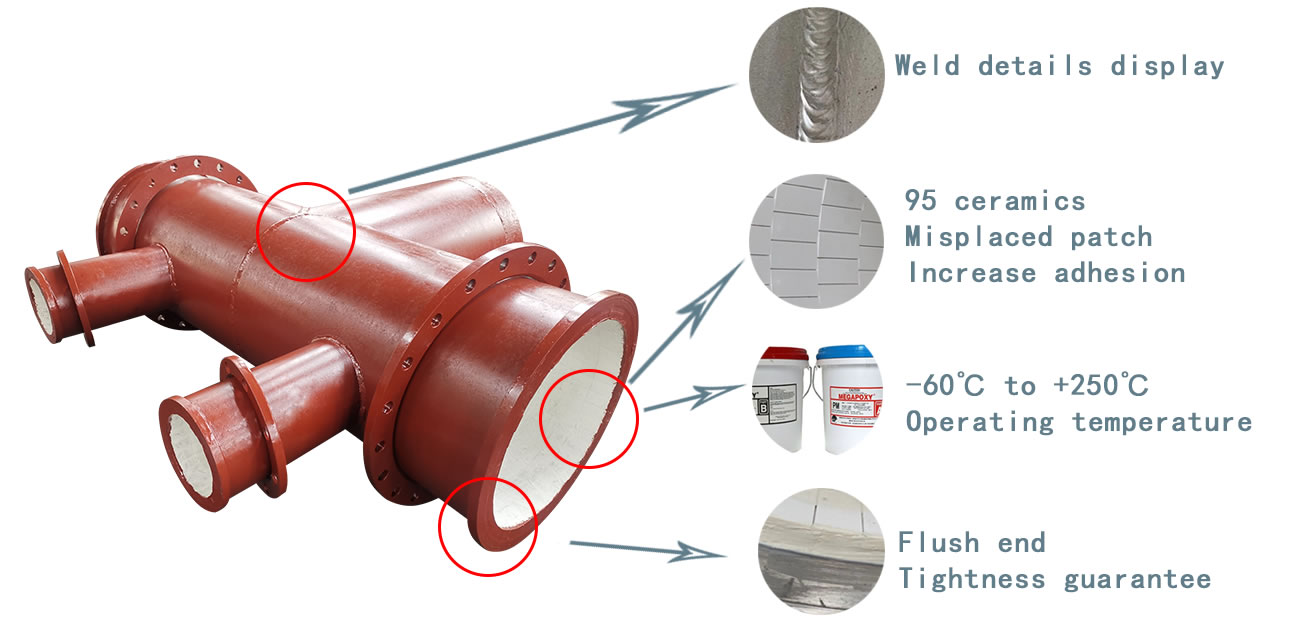

Ceramic tile lining burners for power plants are composed of three layers: outer steel pipe layer, corundum layer, and ceramic glue layer. The inner ceramic layer is white from the surface. The ceramic is generally 95% ceramic, and the temperature is generally below 200°C.

At present, the common ceramic sheets lined with ceramic composite pipes are: ceramic block, dovetail mutual pressure, welding type, mosaic, card slot and so on.It has the characteristics of wear resistance and long service life.

Abrasion resistant ceramic lined pipe, Abrasion Resistant Lined Pipe and Elbow, Wear Resistant Alumina Ceramic Cone

The integral ceramic tube is the ceramic pipe fittings as a whole after firing, with a special filling material will be poured in the steel pipe internal assembly. The pipe wall is smooth, good sealing, with good wear resistance, corrosion resistance.

Abrasion resistant ceramic tile lined steel pipes are composed by steel pipe, adhensive and abrasion-resistant ceramic, we use 20 # seamless steel pipes shaping with hot bending (it is different from centrifugal casting or steel plate rolling), the ceramic tiles bonding with GWJ-350 high temperature-resistant inorganic adhesive which was developed by TsingHua University and to affix abrasion-resistant ceramic in the steel pipes, we use miss match installation instead of directly bonding (this technology was used in the bridge building a thousand years ago), and forms a firm wear-resistance layer after heating solidification. Abrasion resistant ceramic tile lined steel pipes are applicable for the pneumatic powder-feeding, and can be used under a temperature of 350℃without aging and peeling for long life. The service life is 4-5 times than the normal abrasion-resistant pipes.

A high alumina ceramic lined bend is a type of pipe bend that incorporates a lining made of high alumina ceramic material. This lining is designed to provide exceptional wear resistance and protect the bend from abrasion, erosion, and corrosion.

The high alumina ceramic material used in the lining is known for its hardness, strength, and excellent wear resistance properties. It is typically made of alumina (aluminum oxide), which has a high Mohs hardness and is capable of withstanding harsh operating conditions.

High alumina ceramic lined bends are commonly used in industries such as mining, power generation, cement, and chemical processing, where pipelines encounter abrasive materials, high-velocity flows, and corrosive substances.

Ceramic tile lined pipe is our company to absorb similar products at home and abroad on the basis of advanced technology developed a shell for the steel body, within the wear-resistant ceramic tube of the new composite pipe products, with high wear resistance long service life and so on.

The use of anti-off porcelain tube, porcelain tube mosaic, so that paste more flat, more solid with a strong inorganic adhesive paste, wear-resistant steel bowl welding, porcelain and steel body combined to form a double reinforcement to ensure that the porcelain tube does not fall off. The installation of flexible, high wear resistance, processing convenience, the cost is moderate.

Rockwell hardness of high alumina ceramics is up to HRA80-90 which is second only to diamond and far exceeds wear-resistant steel stainless

The wear resistance of high alumina ceramics is 266 times that of manganese steel and 171.5 times that of high chromium cast iron. According to our investigation & follow-up to the clients, the service life of equipment can be prolonged over 10 times under the same working conditions.

High alumina ceramics are inorganic oxides with extremely stable molecular structure and no electrochemical corrosion, thus they can resist erosion of acid, alkali, salt solutions and organic Solvents.

Working temperature of high alumina ceramics can be as high as 1400℃.

High alumina ceramics have the properties of self-lubricity and in adhesion, the roughness is only 1/6 that of steel pipes thus less flow Resistance.

The density of high alumina ceramics is about 3.6g/cm3, which is only half that of steel, thus easy for construction and installation.

Ceramic tile lined pipe is composed of three layers: outer steel pipe layer, corundum layer, and ceramic glue layer. The inner ceramic layer is white from the surface. The ceramic is generally 95% ceramic, and the temperature is generally below 200°C.

At present, the common ceramic sheets lined with ceramic composite pipes are: ceramic block, dovetail mutual pressure, welding type, mosaic, card slot and so on. It has the characteristics of wear resistance and long service life.

The ceramic tile is pasted on the steel pipe with high temperature wear-resistant glue to play a wear-resistant role, and the pipe is generally white. Generally used for large diameter pipes.

Bends and other profile sections can be clad in whole and this process has changed the traditional practice to fabricate bend and other profile sections by drawing polyline without changing flow pattern of material inside piping, greatly reducing conveyance resistance of material.

The ceramic tiles are pasted to the inner wall of the steel pipe with high temperature wear-resistant glue to play a wear-resistant role.

| No. | Process | Standard | Inspection |

|---|---|---|---|

| 1 | Cleaning the inner surface of the fitting | Clean up all the rubbish and floating ash on the inner surface of construction equipment and pipe fittings. | Checked by the construction supervisor. |

| 2 | Rust removal, oil removal, paint removal | The rust, grease, and paint on the bonding surface must be completely removed without leaving any traces. Use iron sand skin, angle grinder, and soft sand skin to polish to see the metallic luster. After cleaning, wipe the surface with a cloth until there is no trace of dirt. | After the inspection and acceptance by the quality inspector, the construction of the next process can be carried out. |

| 3 | Formulated Adhesives | It must be measured in strict accordance with the prescribed proportion, and how much should be used; it must be stirred evenly, and the overall mixing should not be less than 4 times; if the mixed embedded material is added, the binder must be mixed well before adding the mixture and mixing Not less than 3 times. | Assigned by designated personnel. |

| 4 | Repair of the adhesive surface | If there are potholes on the pasting surface, especially if there are large potholes on the pasting surface of the old equipment, the wear-resistant ceramic sheet must be gradually filled with embedded materials. | After the inspection and acceptance by the quality inspector, the construction of the next process can be carried out. |

| 5 | Paste wear-resistant ceramic tiles | There should be no dust or dirt on the surface of the ceramic tiles. The surface of the repaired inlay material must be leveled. The pasting surface must be wiped again. Scrape the adhesive on the pasting surface for 1-2 times and scrape it flat. Scrape the back of the ceramic sheet for 1 It is necessary to ensure that there is a certain thickness of uniform adhesive available for pasting. | Checked by the person in charge of the construction of the pasted ceramic tiles. |

| 6 | Repair of gaps and corners between ceramic tiles | The gaps exceeding 3 mm must be repaired with wear-resistant and anti-corrosion fillers, the edges and corners must be neat, and the bevels must be trimmed with special ceramic tiles and then filled with fillers. | After the repair, the person in charge of the construction and the quality inspector will conduct a comprehensive quality inspection, and submit it to Party A for acceptance after passing the inspection. |

| 7 | Maintenance time | After construction and repair are completed, it can be put into use after natural maintenance for more than 12 hours after acceptance by Party A. |

There are probably hundreds of different methods for packing a abrasion resistant pipe and Elbows, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

The use of Ceramic tile lined pipe and fittings is ideal in services that are prone to erosive wear, and where standard pipe and fittings would fail within 24 months or less.

Ceramics with very low friction factor at low impingement angles decreases the abrasion of materials maximally. Its low density makes it easy to carry and install.

These ceramic lined fittings include elbows, bend, reducers and T pipes are bonded with the abrasion resistant alumina or ZTA ceramic tiles into the inner wall of the carbon steel pipes/elbows with strong-high-temperature resistant adhesive, thus form a firm abrasion resistant layer.

This method mainly applied in the pneumatic&hydraulic conveying system and it can be applied in almost all kinks of pipe fittings like coal powder conveying pipes and elbows,dusting,ash, slag removing pipes ,elbows,reducer,T pipe and cross pipe, even laterals, mining slurry conveying pipe fittings and so on. Almost no limitation for the the diameter of the pipe fittings.

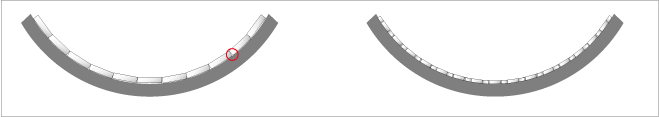

A conventional ceramic tip was arranged with a certain gap between tips in a steel pipe so that the pipe was damaged at the gap before the tip was worn out. The newly developed ceramic tip has a shape with no straight line portion parallel to the transport direction so that the steel pipe is protected until the tip is worn out.

The tailings that are in the pipeline hydraulic transport,which are the phenomena known as the wear abrasion,fatigue,impact.

Have seen that,the use of a tube is 6mm in lenght,the pipe wall thickness was 20mm,and after 8 mounths of using,the bottom is correded till the pipe has 1mm of thickness.

The pipe lined by Dahua has the advantage of the 3mm to 4mm of thickness after 12 mounth of use.

The direction of alignment of ceramics in zig zag,have excellent resistance tc friction of abrasive agents such as sand,gravel,gravel,tailings with solid particles,scale,coal,pulp, tailings from phosphate,salt slag, sludge,ash,..

We are sure that from pure-hearted cooperation we can establish good relationships. Feel free to contact us, we are sure to satisfy you with our professional information, top quality products, best price, and efficient services.

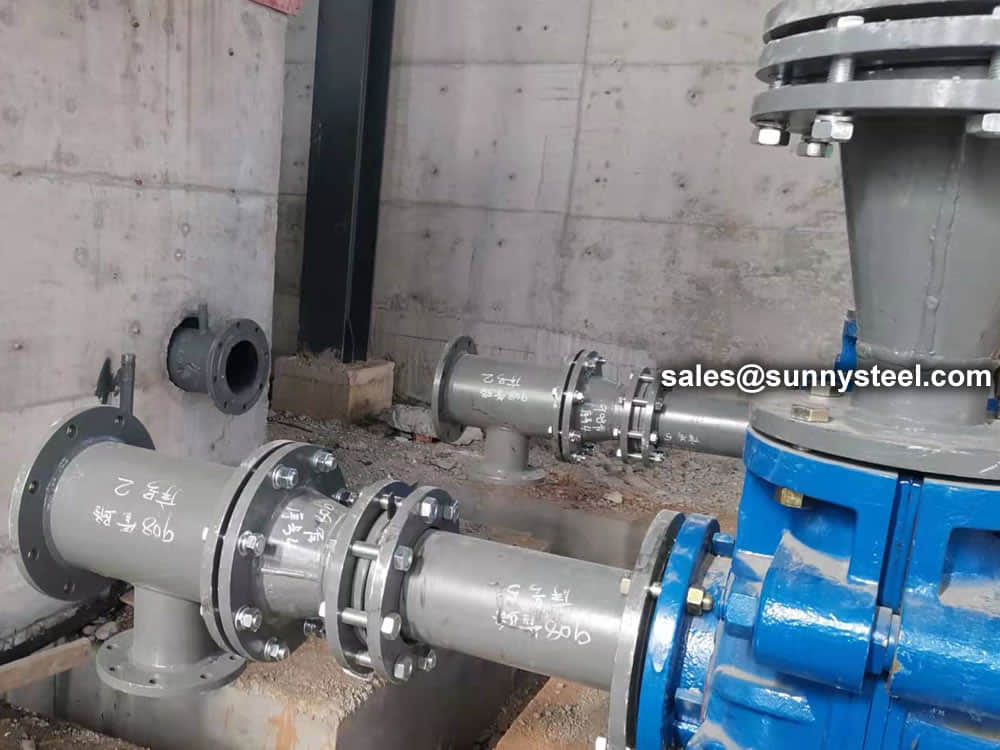

Alumina ceramic lining is often used in industrial settings to protect equipment from abrasion, corrosion, and wear caused by the flow of abrasive materials. The installation site is where these lined components are put into place within an industrial facility. This could include areas such as chutes, pipes, tanks, or other equipment that benefit from the added protection of alumina ceramic lining. The installation ensures that the equipment is properly lined and functioning as intended to enhance its durability and lifespan in challenging environments.

| Ash Pipe & Elbows | Add-Mix Transport Lines | Coal Piping Clinker Chutes |

| Chutes | Coal Conduit Lining | Coal Handing Chute Lining |

| Fan Lining | Pulverizer Housing Liner | Coal Mill Pulverizer Cone Lining |

| Bumer Feed Pipes | Classifer Cone Lining | Cullet Chutes & Hoppers |

| Cyclone Lining | Downcomer Pipe Lining | Coal Mill Exhauster Lining |

| Fan Housings | Drag Convey or Lining | Coal Mill Pulverizer Lining |

The ceramic alumina pressure has superior performance against abrasion,wich has five times more resistant than the conventional ceramic. If the objective is protection of components and reduced maintenance costs,the correct application of anti-abrasive lining led immediately to track the economy. If the objective is protection of components and reduced maintenance costs,the correct application of anti-abrasive lining led imediately to track the economy.

The ceramic pipe lining of hydraulic and pneumatic conveying transport has efficiency and economy,especially in steel tubes.Where they have great advantages, increasing the time of life.

A cross section of a steel pipe after 1 year of used

The perfect choice Resistance to abrasion is superior to all material available on the market

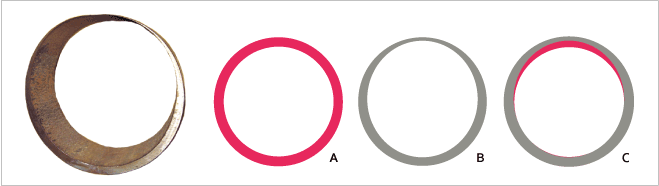

Metals have good ductility but poor resistance to abrasion - which means that abrasion prevention is required when metal pipes are used in high-temperature fluid catalyst service. On the other hand, ceramics possess great hardness and abrasion resistance, but they are brittle. Metal Ceramic double pipe is a hybrid pipe using metal as an outer pipe and a ceramic material for inner pipe segments, applied together to utilize the two materials' advantages. Hence excellent wear-resistance and good corrosion resistance of the ceramics and high strength and toughness of metal can be well combined to get a comprehensive advantage of wear-resistance, corrosion-resistance and anti-scaling. They are suitable for applications in heavy wear working conditions.

Ceramics are among the hardest materials available and provide ultimate wear resistance in piping. In high wear applications, ceramic lined pipes have been demonstrated to be cost-effective by increasing service life and reducing maintenance costs. Sunny Steel supply ceramic lined abrasion resistant steel pipes to your custom dimensions and budget. Our ceramic linings are the highest quality materials available to ensure that we provide the most cost-effective solutions for our clients.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.