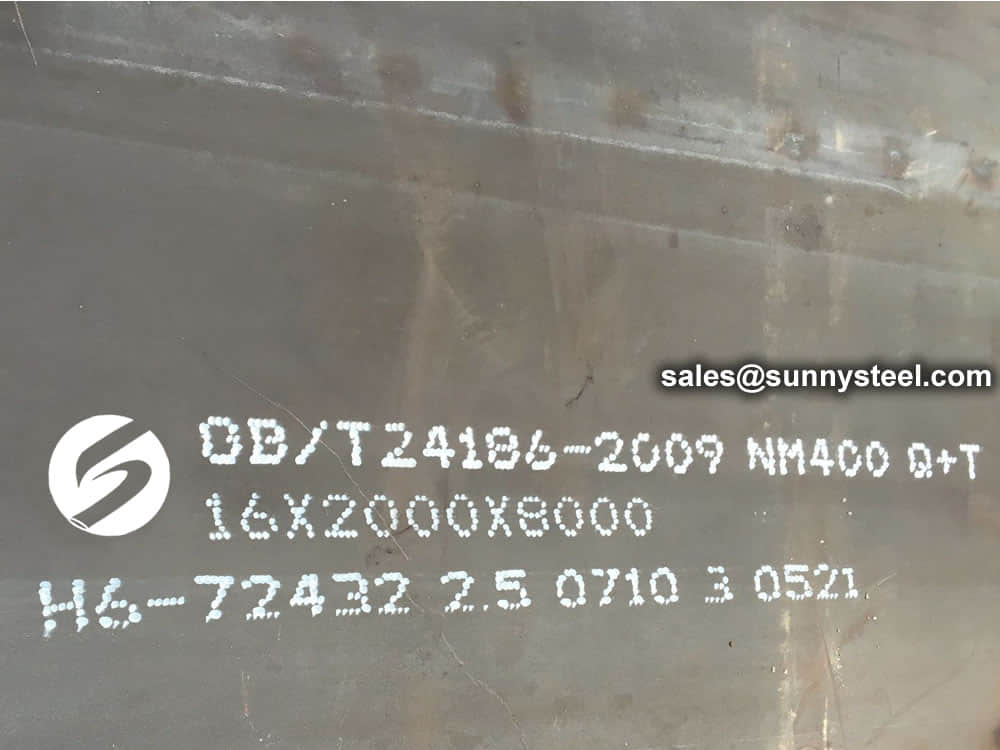

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

NM400 steel plates are demanded widely by many commercial industries as they offer great wear resistance, high strength and thus significantly improving wear resistance of heavy mechanical parts.

They are also known as wear–resistant plates. As compared to ordinary or low alloy steel mechanical properties of NM400 steel plate is 3 to 5 times more. Thus, the service life of this grade alloy helps to reduce the cost of production. The processing and manufacturing of the product of structural steel plate is done according to the suitability and necessity of the customers. Mostly this grade is brought into application in various manufacturing enterprises.

| Chemical element | Data |

|---|---|

| C | ≤0.24 |

| Si | ≤0.50 |

| Mn | ≤1.6 |

| P | ≤0.025 |

| S | ≤0.015 |

| Cr | 0.4~0.8 |

| Mo | 0.2~0.5 |

| Ni | 0.2~0.5 |

| B | ≤0.005 |

| CEV |

| Grade | Thickness | Tensile Test MPa | Hardness | ||

|---|---|---|---|---|---|

| mm | YS Rel MPa | TS Rm MPa | Elongation % | ||

| NM400 | 10-50 | ≥620 | 725-900 | ≥16 | 380-460 |

Wear resistant steel plate refers to the special plate products used under large area wear condition. At present, the commonly used wear-resistant steel plates are made of ordinary low-carbon steel or low-alloy steel with good toughness and plasticity by surfacing welding with a certain thickness of alloy wear-resistant layer with high hardness and excellent wear resistance. In addition, there are cast wear-resistant steel plates and alloy quenched wear-resistant steel plates.

The series of NM wear-resistant steel combined the properties including high strength, high hardness, high wear resistant, weldable, bendable and mainly applied in:

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.