ASTM A106 Gr.B Pipes

ASTM A106 Gr.B pipes are seamless pipes known for their seamless construction and pressure capabilities.

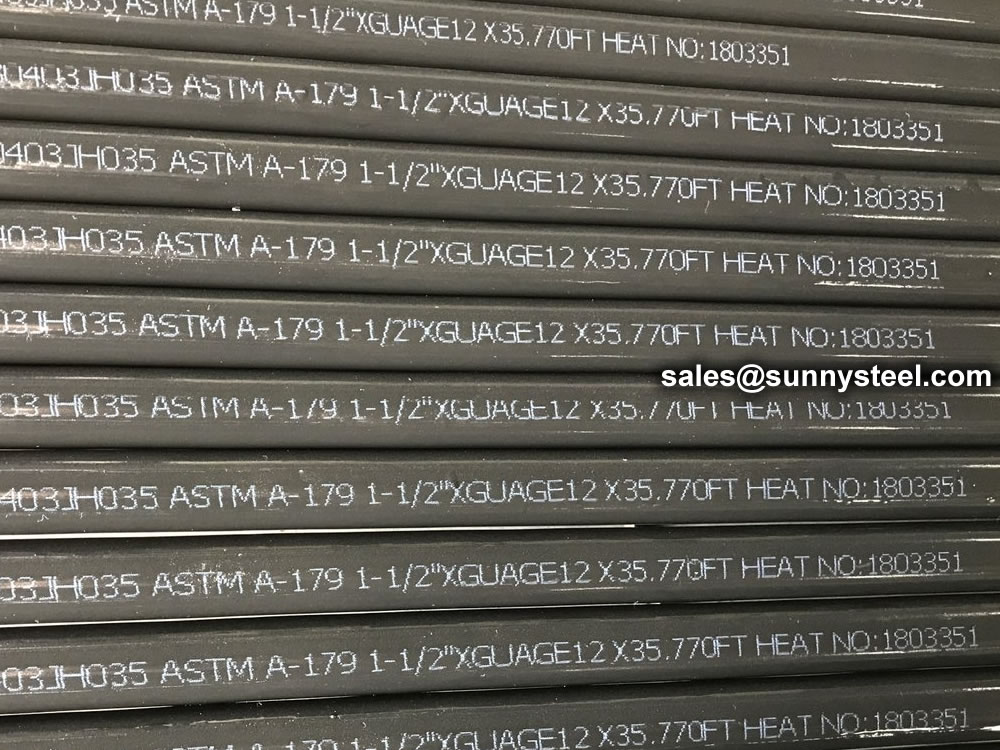

ASTM A179 Seamless Boiler Tubes are manufactured in cold-drawn seamless, material in low carbon steel for heat exchanger and condenser.

Download PDFASTM A179 Seamless Boiler Tubes, A179M Seamless Cold-Drawn Tube,Low-Carbon Steel Heat-Exchanger and Condenser Tubes,ASTM A179 heat exchange tube

ASTM A179 Seamless Boiler Tubes which are made from the finest and most superior raw materials which we source from our local vendors. The ASTM A179 is a standard which covers specifications for the A179 Tube material in terms of its minimum wall thickness. ASTM A179 Tubes shall be made by the seamless process and shall be cold drawn. Heat and product analysis shall be performed wherein steel materials shall conform to required chemical compositions of carbon, manganese, phosphorus, and sulfur. The steel materials shall also undergo hardness test, flattening test, flaring test, flange test, and hydrostatic test.

When we place a specific order for SA 179 tubing, we should include below material specifications:

Low-carbon steel continuous, minimal wall thickness tubing for condensers, heat exchanger tubes, as well as other heat transfer applications are covered by STM A179. Seamless, cold-drawn low-carbon alloy steel pipe is covered by the ASTM A179 (SA 179) required specifications.

For SA179 heat exchanger tubes, the minimum yield strength is 26 Ksi 180 Mpa, the minimum tensile strength is 47 Ksi 325 Mpa, as well as the minimum stretch is 2 inches or 50 millimeters (about 1.97 in) at 35%.

The elemental composition is as follows: Mn (Manganese) 0.27-0.63 percent, P (Phosphorus) max. 0.035 percent, S (Sulfur) 0.035 percent, and C (Carbon) 0.06-0.18 percent. The ASTM A179 Heat Exchanger Tube is a robust, flexible tubing with long-bearing capabilities.

The OD range of the SA 179 seamless carbon cold-drawn steel tubes is 1/8″ to 3″, or 3.2mm (about 0.13 in) to 76.2mm (about 3 in). However, mechanical qualities are not relevant for sizes down to 1/8″ & 3.2 mm (about 0.13 in), or widths less than 0.015 inches and 0.4 mm (about 0.02 in). Other diameters & widths smaller than the mentioned specifications are also relevant to this standard.

ASTM A179 Heat Exchanger Tubes, Hot Rolled as well as Cold Drawn, Seamless, 1/4″ NB – 2″ NB (Nominal Bore Size) 1 mm (about 0.04 in) to 8 mm (about 0.31 in) in width, outside diameter Width, lengths of up to 27000mm (about 88.58 ft) in maximum length with plain ends, beveled ends, or coupling, etc.

ASTM A179 is a standard specification for seamless cold-drawn low-carbon steel tubes used in tubular heat exchangers, condensers, and similar applications.

The ASTM A179 tubes are produced through a cold-drawing process, which helps to improve their dimensional accuracy and surface finish.

ASTM A179 Seamless Boiler Tubes are widely used in industries such as petroleum, chemical, medical, food, light industry, machinery, instrument, include industrial pipeline and mechanical structure parts, etc.

ASTM A179 covers minimum-wall thickness, seamless cold-drawn low-carbon steel tubes for tubular, heat exchanger, condensers, and other heat transfer services. seamless ASTM A 179 steel tube is supplied and produced by cold drawning method. Chemical composition contains carbon, manganese, phosphorus, and sulfur.

ASTMA179/ASME SA179 standard is applicable for steel pipes together with outside diameter of 1/8in-3in. (32 mm to 76.2 mm). Our rolling technology has reached the international advanced spot. JST is able to manufacture cold drawn seamless steel tubes with uniform wall depth. Their tolerance is relatively smaller standard your own.

When seamless carbon steel pipes are during the last cold drawing procedure, they will enter micro oxidization and non-oxidation heat treatment furnace for thermal treatment (Temperature is 1200℉ (650℃) if not more.). This makes the surface of cold drawn seamless steel tubes match the no oxide scale standards, and guarantees smooth surface and stable performance.

JST adopts professional hardness testing equipment to find out the hardness of seamless carbon steel pipes. The Rockwell hardness value not able to exceed 72 HRB.

Top rated program customers' requirements, we can analyze the cold drawn seamless steel tube advertise its chemical composition meet standards. We choose one from 250 pipes or select one in a furnace to investigate. If the product analysis fails, then choose another two seamless carbon steel pipes. All elements of two steel pipes tend to be in accordance with standards, and then these pipes can be delivered.

Note:

| OD(mm) | Wall Thickness Unit(mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5 - 7 | 7.5 - 8 | 8.5 - 9 | 9.5 - 10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ133 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ140 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ146 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ152 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ159 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ168 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| C | Si | Mn | P | S | Mo | Cr | V |

|---|---|---|---|---|---|---|---|

| 0.06-0.18 | / | 0.27-0.63 | ≤0.035 | ≤0.035 | / | / | / |

| Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

Hardness (HRB) |

|---|---|---|---|

| ≥325 | ≥180 | ≥35 | ≤72 |

ASTM A450 covers carbon and low alloy steel tube. Steel samples shall be melt processed and shall either be ingot cast or strand cast. Heat and product analyses shall be performed on the steel materials. Steel specimens shall also undergo tensile tests and shall conform to required values of yield strength and elongation. Flattening test, reverse flattening test, flaring test, flange test, hardness test, hydrostatic test, air underwater pressure test, and nondestructive tests shall be performed on the steel materials.

| OD In (mm) | + | - | WT In(mm) | + | - |

|---|---|---|---|---|---|

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 11.1/2(25.438.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2<2(38.150.8) | 0.20 | 0.20 | |||

| 2<2.1/2(50.863.5) | 0.25 | 0.25 | |||

| 2.1/2<3(63.576.2) | 0.30 | 0.30 | |||

| 34(76.2101.6) | 0.38 | 0.38 | |||

| >47.1/2(101.6190.5) | 0.38 | 0.64 | |||

| >7.1/29(190.5228.6) | 0.38 | 1.14 |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.