Rope Coring Drill Pipe

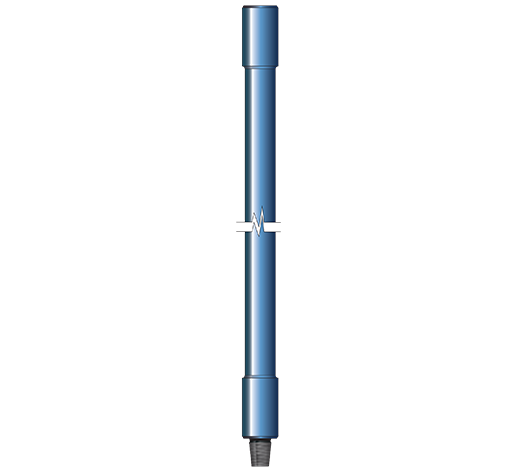

Coring with rope is an advanced drilling method which can obtain the core without raising the bit or lesser raising bit frequency.

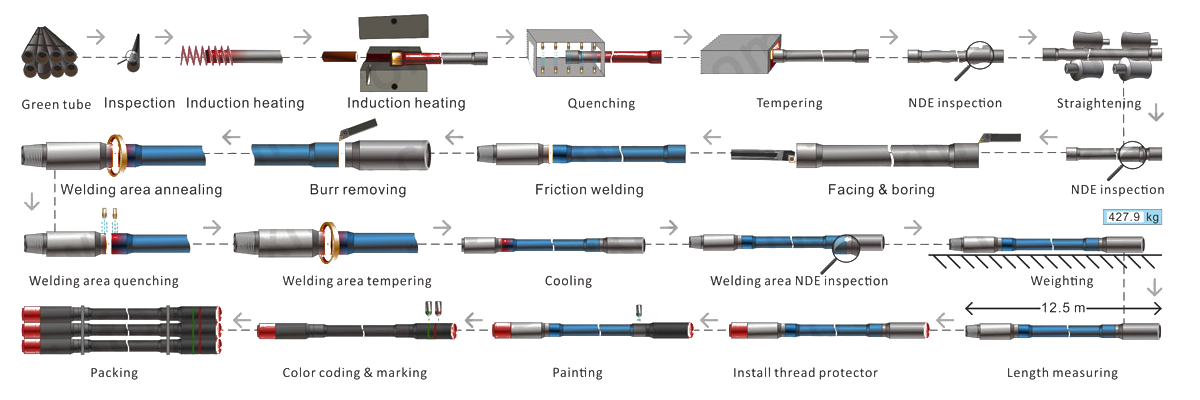

The seamless drill pipe is crafted through friction welding between the drill pipe body and the joint.

While ensuring the structure and mechanical properties meet technical requirements, the key to quality control lies in the structure and mechanical properties of the friction welding weld and the heat-affected zone.

From 2 3/8” to 6 5/8″

Range 1: 18 ft. to 22 ft.

Range 2: 27 ft. to 30 ft.

Range 3: 38 ft. to 45 ft.

The drilling tools connected with drill rods and transfer the power. Usually a drill string includes drill collars, drill pipe, stabilizers, special connectors and kelly. Drill pipe both ends screw thread for connecting the drilling rig located at the bottom and mill equipment. Drill pipe must be capable for external pressure, twisting and work in heavy vibration.

The mechanical properties of the friction welding seam and heat-affected zone are determined by their structure. Hence, studying the microstructure characteristics of these areas and their impact on mechanical properties is crucial for guaranteeing and improving drill pipe quality.

Friction welding of drill pipes is a solid-phase welding process. Detailed studies on the structure of fusion welding welds and heat-affected zones have been conducted, but research on the structure of friction welding welds and heat-affected zones of drill pipes is limited.

| Series | Classification | OD(mm) | WT(mm) | ID(mm) |

|---|---|---|---|---|

| BTW | Drilling Rod | 56.6 | 4.05 | 48.5 |

| Inner Tube | 46.6 | 1.8 | 43 | |

| Outer Tube | 57.2 | 4 | 49.2 | |

| Stop Ring | 60 | 5.6 | 48.8 | |

| NTW | Drilling Rod | 73.1 | 4.4 | 64.3 |

| Inner Tube | 61.5 | 2.05 | 57.4 | |

| Outer Tube | 73.5 | 4.4 | 64.7 | |

| Stop Ring | 75.3 | 5.35 | 64.6 | |

| HTW | Drilling Rod | 91.3 | 5.15 | 81 |

| Inner Tube | 78.4 | 2.8 | 72.8 | |

| Outer Tube | 93 | 5.7 | 81.6 | |

| Stop Ring | 95.45 | 7 | 81.45 |

Thread/Connection Types of Drill Pipe

NC26, NC31, NC38, NC40, NC46, NC50, 5-1/2 FH, 6-5/8 FH

XT connections facilitate the use of larger drill pipe in a set hole size, such as 5⅞ in. drill pipe with XT 57 in an 8½ in. hole size.

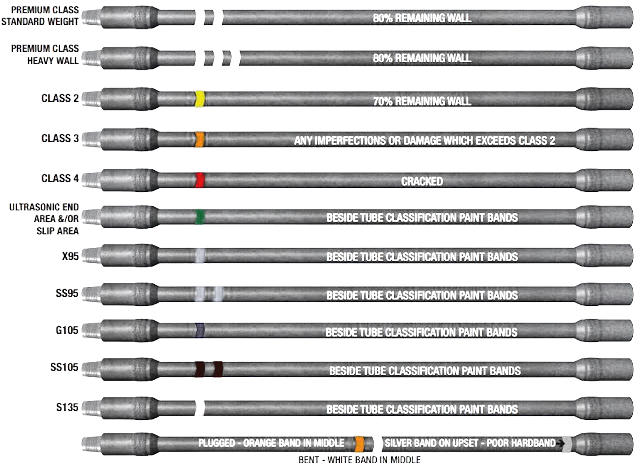

X57, X75, X39, X95

The tool joints are connected to the tubes through inertia welding with computer-monitored precision. Concentricity is closely monitored and controlled, and the parameters of each weld are electronically recorded and traceable to each joint. Following the removal of weld flash, the weld area undergoes austenitization, quenching, and tempering to achieve the necessary mechanical properties. Heat treatment cycles for each weld are compared to specific parameters and recorded for traceability. After all steps and machine marks are polished from the outer and inner diameter areas, hardness testing, ultrasonic testing, and wet magnetic particle inspections are employed to verify the integrity of each weld zone.

Drill pipe corrosion is a critical issue for any drilling operation, particularly under high pressure, high temperature downhole conditions. However, most laboratory studies have been conducted under ambient and static conditions, with only a few downhole studies based on flow loops showing inconsistent results. In this study, we proposed a novel simple method to simulate pipe corrosion/erosion in a reservoir-like environment under both static and dynamic conditions, and investigated the influences of well conditions, including temperature, pressure and salinity of water-based drilling fluids, on the corrosion behaviour of drill pipe. The results showed that the erosive effect of the drilling fluid (excluding cuttings) was negligible. It was also found that the corrosion rate increased with an increase in temperature, pressure and speed, but decreased with an increase in salinity. In addition, the proposed method can be used to simulate other complicated conditions.

Drill pipe is the basic component of drill string. Its main function is to transmit torque and transport drilling fluid, and the wellbore is continuously deepened by the gradual lengthening of the drill pipe. Therefore, drill pipe occupies a very important position in oil drilling.

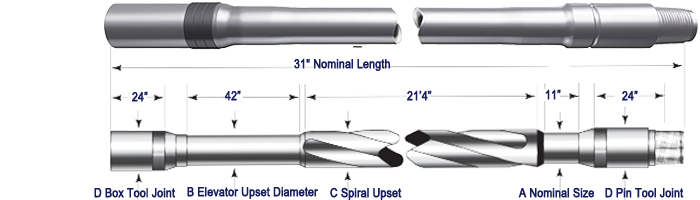

Drill pipe structure The drill pipe is made of seamless steel pipe, and the wall thickness is generally 9-11mm; it is composed of two parts: the drill pipe body and the drill pipe joint. The pipe body and the joint are butt welded together by friction welding.

For components on the drill string, the weight per unit length of the weighted drill pipe is moderate. This drill pipe is a heavy wall body with extended joints.

The outer diameter of the weighted drill pipe is similar to that of the standard drill pipe to facilitate the operation of the drilling rig. The characteristic of weighted drill pipe is that it can bear the pressure like a drill collar. A unique feature of weighted drill pipe is the wear band in the center of the drill pipe. The wear belt can act as a stabilizer, improve the rigidity of the weighted drill pipe in the drill string, and reduce the well deviation.

The weighted drill pipe is similar to the oil drill pipe, and it is also a hollow steel column with a length of about 10 meters. However, the weight of a single piece is heavier than that of the oil drill pipe, and the wall thickness is 2 to 3 times that of the drill pipe. The weighted drill pipe is connected between the drill pipe and the drill collar. It can also replace the role of part of the drill collar, but its suspension is simple, the tripping and tripping operation is convenient, and the tripping and tripping time can be saved.

| Specifications | Steel Grades |

|---|---|

| ASTM A-210 / ASME SA-210 | Gr. A1; C |

| BS 3059-1 | Gr. 320 |

| BS 3059-2 | Gr. 360; 440; 620; 622; |

| EN 17175 | 16Mo3 |

| EN 10216/1 | P235TR1; P235TR2; P265TR1; P265TR2 |

| EN 10216/2 | P235GHTC1; P235GHTC2; P265GHTC1; P265GHTC2 |

| ASTM A-209 ASTM A-213 ASME SA-213 |

Gr. T1; T11; T12; T22; T5; T9; T91; T92 |

| ASTM A-335 / ASME SA-335 | Gr. P1; P11; P12; P22; P5; P9; P91; P92 |

| Grade | Mpa(Yield Strength) | Mpa(Tensile strength) | (%)Elongation | Note |

|---|---|---|---|---|

| R780 | ≥520(Rp0.5) | ≥780 | ≥15(A50) | Standard: JIS G3465-2006 Type and Brand:STMR780 |

| E75 | 517~724(Rp0.5) | ≥689 | The requirements of elongation is referred to the standard of cross sectional area of tensile specimen;which can be met only when the material heat treatment method are correct | API 5DP DN EN ISO11961-2009 (European unit co efficient:6.895) [75*6.895=517;135*6.895=931] |

| X95 | 655~862(Rp0.5) | ≥724 | The requirements of elongation is referred to the standard of cross sectional area of tensile specimen;which can be met only when the material heat treatment method are correct | API 5DP DN EN ISO11961-2009 (European unit co efficient:6.895) [75*6.895=517;135*6.895=931] |

| G105 | 724~931(Rp0.6) | ≥793 | The requirements of elongation is referred to the standard of cross sectional area of tensile specimen;which can be met only when the material heat treatment method are correct | API 5DP DN EN ISO11961-2009 (European unit co efficient:6.895) [75*6.895=517;135*6.895=931] |

| S135 | 931~1138(Rp0.7) | ≥1000 | The requirements of elongation is referred to the standard of cross sectional area of tensile specimen;which can be met only when the material heat treatment method are correct | API 5DP DN EN ISO11961-2009 (European unit co efficient:6.895) [75*6.895=517;135*6.895=931] |

| ZT380 | ≥380 | ≥640 | ≥14 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT490 | ≥490 | ≥690 | ≥12 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT520 | ≥520(Rp0.5) | ≥780 | ≥15(A50) | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT540 | ≥540 | ≥740 | ≥12 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT590 | ≥590 | ≥770 | ≥12 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT640 | ≥640 | ≥790 | ≥12 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT740 | ≥740 | ≥840 | ≥10 | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT850 | ≥850 | ≥950 | ≥14(A50) | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| ZT950 | ≥950 | ≥1050 | ≥13(A50) | GB/T9808-2008 GB/T16950-2014 Drilling 590Mpa Min Yield Strength equivalent to DZ60 |

| DZ40 | ≥392 | ≥637 | ≥14 | YB/T5052-93 DZ50: Min Yield strength og 50Kgf mm2 in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

| DZ50 | ≥490(50*9.8=490) | ≥686 | ≥12 | YB/T5052-93 DZ50: Min Yield strength og 50Kgf mm2 in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

| DZ55 | ≥540 | ≥735 | ≥12 | YB/T5052-93 DZ50: Min Yield strength og 50Kgf mm2 in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

| DZ60 | ≥588(60*9.8=588) | ≥764 | ≥12 | YB/T5052-93 DZ50: Min Yield strength og 50Kgf mm2 in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

| DZ65 | ≥637 | ≥784 | ≥12 | YB/T5052-93 DZ50: Min Yield strength og 50Kgf mm2 in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

| DZ75 | ≥735 | ≥833 | ≥10 | YB/T5052-93 DZ50: Min Yield strength og 50Kgf mm2 in geological drilling DZ60: Generally 45MnMoB used DZ50: Generally 40Mn2 used |

Drill pipe plays a critical role in oil and gas exploration, withstanding immense stress, strain and heat during drilling operations.

Its importance lies in its ability to withstand these challenging conditions, as failure could result in significant delays and financial loss. The demands on drill pipe can be severe, especially as well depth increases. Drilling may involve challenging environments such as rock formations or underwater operations. The size, grade and quantity of drill pipe is determined by the well design, which is influenced by depth and subsurface geology. As exploration expands into more challenging areas, there is a growing demand for higher grade and better quality drill pipe.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.