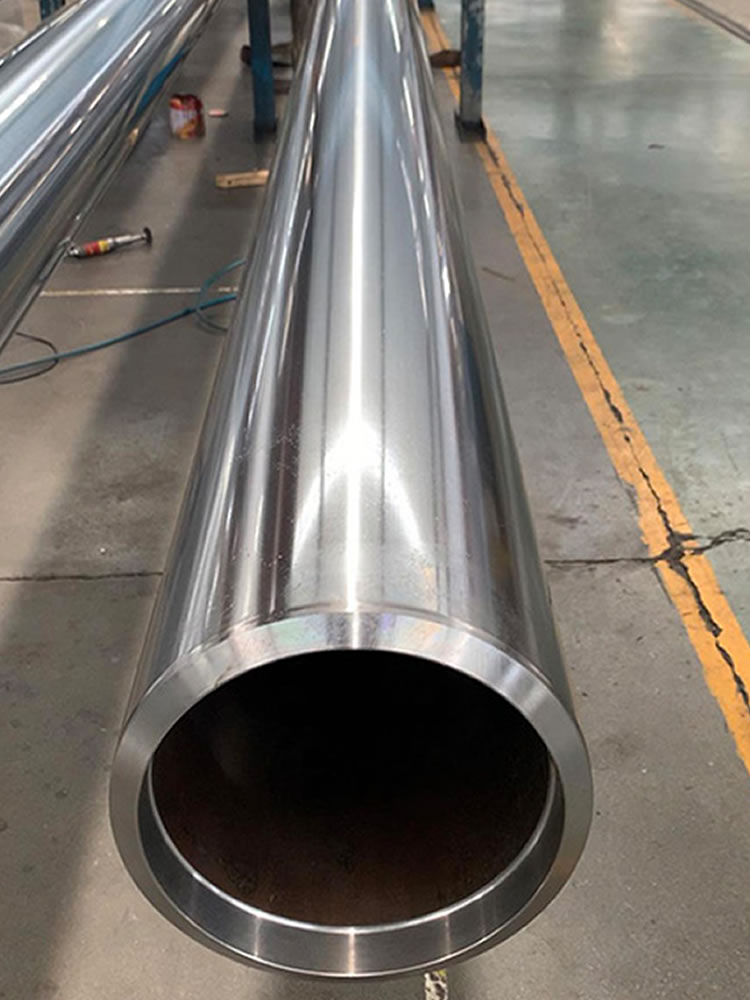

Bearing Pipes

Pipes designed for bearing loads, offering high strength and durability.

Gas cylinder steel pipe is used in manufacturing seamless steel gas cylinders, automotive CNG cylinders and composite cylinders.

Steel pipes used for gas cylinders are typically made from grades such as 37Mn, 34Mn2V, 35CrMo, and others. These grades of steel are chosen for their suitability in producing gas cylinder steel tubes . It provides excellent hot rolled thin-walled seamless steel pipe for tube-type bottle. This high-pressure gas cylinder pipe has such features: quality inside and outside surface; uniform wall thickness; light mass; high productivity and yield and low cost, etc.

Steel pipes for gas cylinders are designed to meet specific standards and requirements to ensure the safe and efficient storage and transportation of gases. These pipes are typically seamless and made from high-strength steel alloys that can withstand high pressures.

GB 18248: Seamless steel tubes for gas cylinderGB 28884: Seamless steel tubes for large volume gas cylinderASTM A519: Standard Specification for Seamless Carbon and Alloy Steel Mechanical TubingJIS G3429: Seamless steel tubes for high-pressure gas cylinderBS EN ISO 11120: Gas cylinders - Refillable seamless steel tubes for compressed gas transport, of water capacity between 150L and 3000L - Design, construction, and testingCommon steel grades used for gas cylinder pipes include:

37Mn34Mn2V35CrMo30CrMo34CrMo4 (EN10297-1 standard)4130X (equivalent to 30CrMoE)The available sizes of seamless steel pipes for gas cylinders can vary, but typically include:

Steel pipes for gas cylinders are critical components in the storage and transportation of gases. They must meet stringent standards and undergo rigorous testing to ensure safety and reliability. The choice of material and manufacturing process is crucial for the performance of the gas cylinder in its intended application.

For more detailed information or specific inquiries, it is recommended to consult with manufacturers or refer to the official standards and technical specifications.

Steel pipes for gas cylinders are used in various applications, including:

Cylinder tubes are critical for applications requiring reliable and efficient movement in hydraulic or pneumatic systems. Manufactured to precise tolerances, these tubes ensure optimal sealing and smooth operation in demanding industrial environments.

Generally, this pipe used for hydraulic equipment and institutional structure which has high precision and good surface finish, which including piston and plunger type

BS EN 10297-1 Seamless circular steel tubes for mechanical and general engineering purpose- Technical delivery condition

BS EN 10305-1 Steel tube for precision application-Technical delivery conditions

GB/8163 Seamless steel pipe for liquid service

30 Mn2, 27SiMn, Q345, E355, E470, 20# etc

Dimensional precision: Cylinder pipe with few deviation in wall thickness tolerance, wall unevenness, outside tolerance and ovality

Surface Quality: Through the plug, mandrel and furnace temperature can control internal and external surface finish, control tube oxidation skin pits and others defect that can meet the requirements of clients

Implement specifications GB 18248, GB28884 and JIS 3429. Products are used for the manufacture of firefighting gas cylinder, industrial gas cylinder and vehicle-borne gas cylinder. Products can be ordered in accordance with the client’s requirements. It has been applied in seamless tube-type bottle bottom closing in key technology, adopting the gas cylinder pipe manufacture from punching drawing billet to thin-walled seamless steel pipe production. And this change is welcomed by users and has been an trend.

| Usage | Specification No. | Steel Grade |

|---|---|---|

| Seamless Steel Pipe used for Gas Cylinder | GB /T18248 | 37Mn, 34CrMo4, 35CrMo, 30CrMnSiA, 30CrMo |

| Fire-fighting gas cylinders, industrial gas cylinders, vehicle gas cylinders | JIS G3429 | 37Mn, 34Mn2V, 30CrMo, 35CrMo, STH11, STH12, STH21, STH22, or anything else |

| Seamless Steel Pipe used for Gas Cylinder with Large Volume | GB/T28884 | 30CrMoE(4130X), 32CrMoE(4142) |

Products can be ordered in accordance with the client’s requirements.

30CrMoE seamless tubes are used for manufacturing seamless steel tubes for gas cylinders with a capacity of 300L~3 000L.

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni | Cu | |

|---|---|---|---|---|---|---|---|---|---|---|

| 30CrMoE | 1 | 0.25-0.35 | 0.15-0.35 | 0.4-0.9 | ≤0.02 | ≤0.01 | 0.8-1.1 | 0.15-0.25 | ≤0.3 | ≤0.2 |

| 2 | 0.26-0.34 | 0.17-0.37 | 0.4-0.7 | ≤0.02 | ≤0.01 | 0.8-1.1 | 0.15-0.25 | ≤0.3 | ≤0.2 |

*30CrMoE 1 is equal to 4130X.

| Standard | T.S/MPa | Y.S/MPa | E/A % | Yield Ratio | Hardness/HBW | -40℃ Impact Test/J |

|---|---|---|---|---|---|---|

| 30CrMoE | ≥720 | ≥485 | ≥20 | ≤86 | ≤269 | ≥32 |

NDT: UT 100%.

JIS G3429 Seamless tubes for high pressure gas cylinder

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| STH11 | ≤0.50 | 0.10-0.35 | ≤1.80 | ≤0.035 | ≤0.035 | / | / | / |

| STH12 | 0.30-0.41 | 0.10-0.35 | 1.35-1.70 | ≤0.030 | ≤0.030 | / | / | / |

| STH21 | 0.25-0.35 | 0.15-0.35 | 0.40-0.90 | ≤0.030 | ≤0.030 | ≤0.25 | 0.80-1.20 | 0.15-0.30 |

| STH22 | 0.33-0.38 | 0.15-0.35 | 0.40-0.90 | ≤0.030 | ≤0.030 | ≤0.25 | 0.80-1.20 | 0.15-0.30 |

| Tolerance | Data |

|---|---|

| Outside diameter: | 0.01 |

| Wall thickness: | 0.3 |

| Wall thickness disparity: | Within 20% of the nominal wall thickness |

| Length: | >+30mm |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.