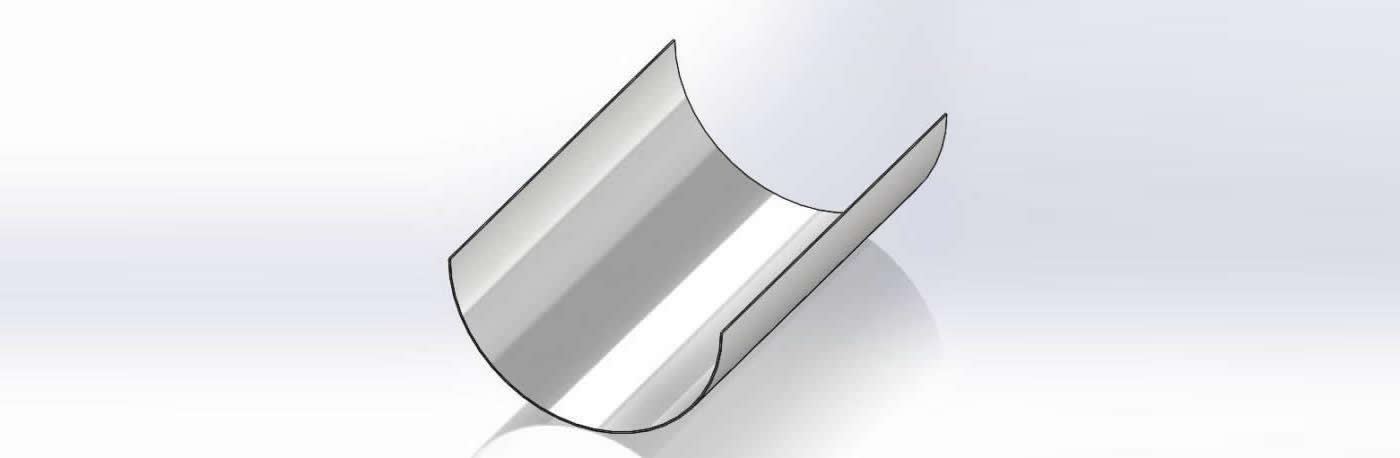

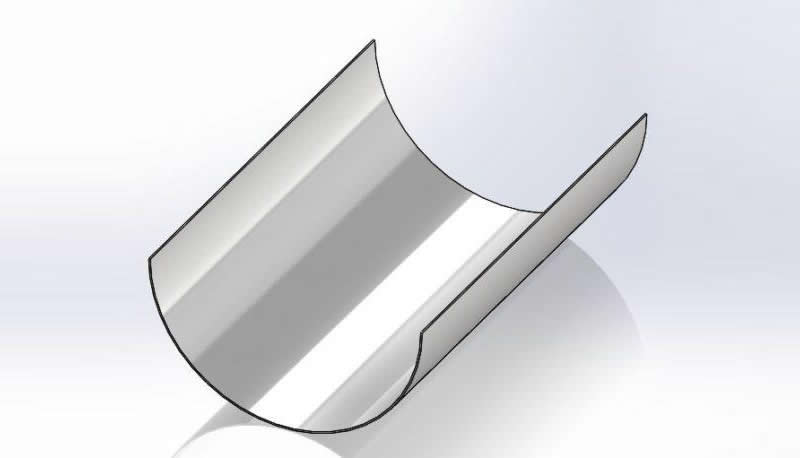

U-Shaped Snap Ring

U-shaped snap rings are versatile and reliable components essential for securing parts in various mechanical assemblies.

Explore the design, applications, and manufacturing processes of custom clips, including metal and spring clips, tailored to meet specific requirements across various industries.

Download PDFCustom Clips are specialised fasteners or clamps designed to meet specific requirements in various applications. These clips can be customised in terms of material, size, shape and coating to meet the unique requirements of a project, whether in the automotive, industrial, construction or other sectors. They provide secure, durable fastening solutions and can be designed to handle different loads, environmental conditions and operational stresses. Custom clips are often used where standard clips do not fit or provide the required performance.

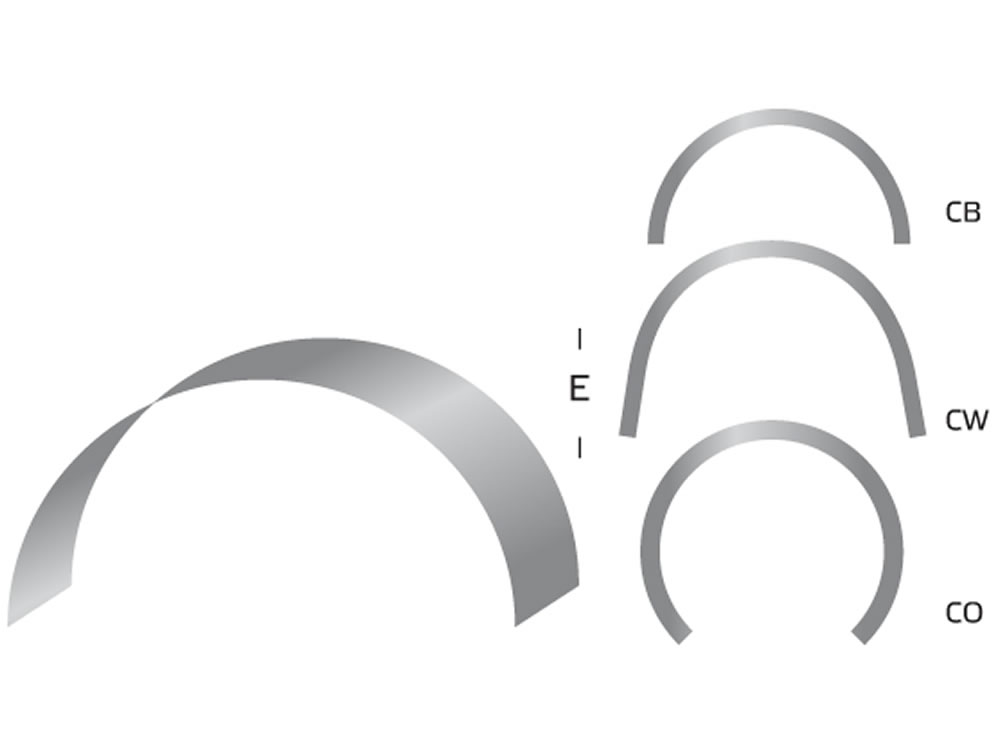

Clip Style

Tube Diameter

Angle of Wrap

Gauge

Material

Clip Length

Clip Extension (E)

Sunny Steel has an extensive inventory in sheet, bar, and welding materials maintained for heat resistant, corrosion resistant, and high temperature alloys. All products are purchased to proprietary customized specifications as well as normal industry standards with supporting documentation. The ability to obtain mill direct pricing and consignment inventory control has enabled our team to provide competitively priced products and control delivery of projects.

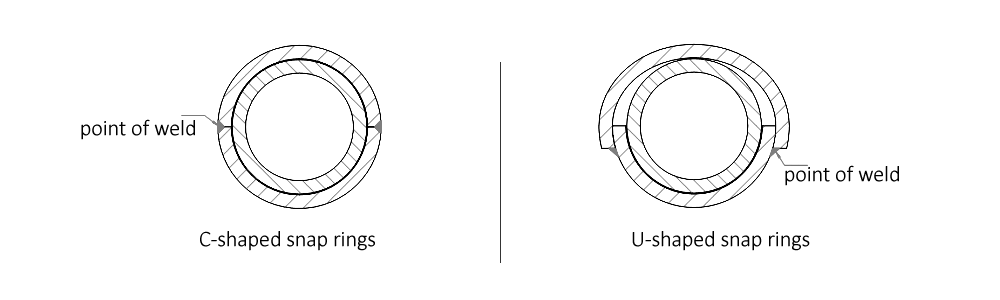

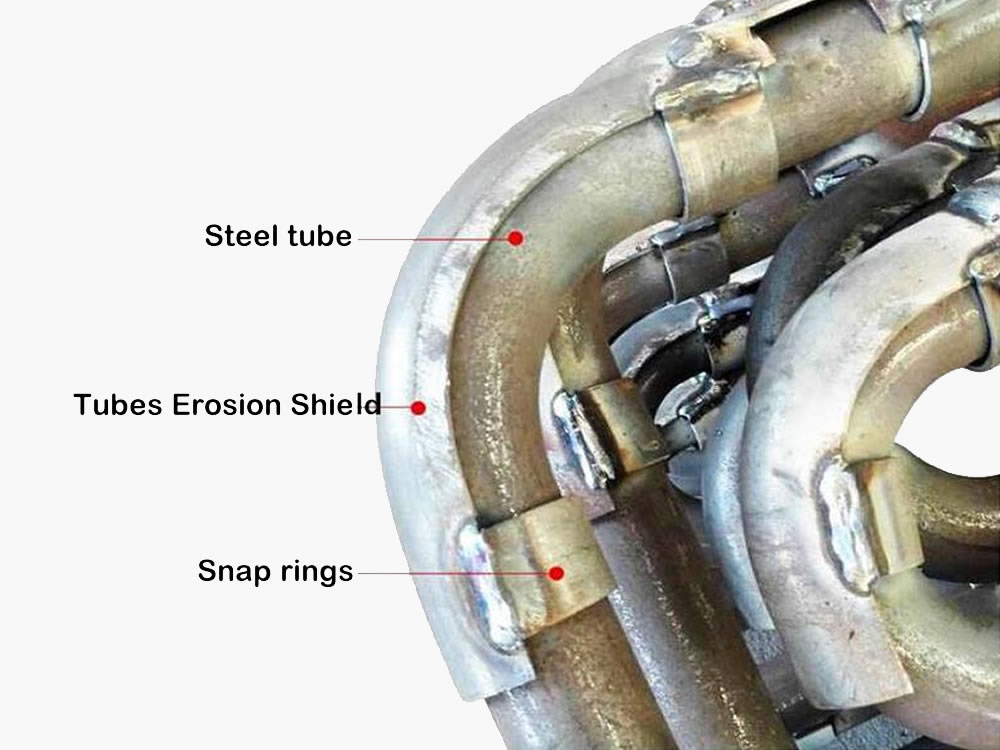

The snap ring and boiler tube erosion shields are overlapped and welded, generally about 190-200 degrees erosion shields is a 180-degree semicircle), but also leave a welding position for easy welding and fixing. Generally, each piece of boiler tube erosion shields needs to be equipped with 2-4 snap rings with a pitch of 200-500mm.

The anti-wear snap ring is also called a clamp, buckle, tube clamp, etc.

The main role of the anti-wear tile snap ring: the role of fixing the anti-wear tile to avoid problems such as the anti-wear tile falling off during installation.

The types of common anti-wear tile rings can be divided into: u-shaped lap type snap ring, butt-type semicircular snap ring.

Custom clips are specialized fasteners designed to hold, secure, or position components in various assemblies. Tailored to meet specific requirements, these clips are essential in industries ranging from automotive and aerospace to consumer electronics and medical devices. Their versatility and adaptability make them indispensable in modern manufacturing and engineering.

Custom clips play a vital role in a multitude of industries, offering tailored solutions for fastening and securing components. By understanding their design features, applications, and manufacturing processes, engineers and designers can effectively incorporate custom clips into their products, enhancing functionality and reliability.

Snap rings are used in conjunction with boiler tubes erosion shields, which is a clip that easily installs boiler tubes erosion shields to the tube.

The snap ring and Boiler Tubes Erosion Shields are overlapped and welded, generally about 190-200 degrees Erosion Shields is a 180-degree semicircle), but also leave a welding position for easy welding and fixing. Generally, each piece of Boiler Tubes Erosion Shields needs to be equipped with 2-4 snap rings with a pitch of 200-500mm.

The anti-wear snap ring is also called clamp, buckle, tube clamp, etc.

The main role of the anti-wear tile snap ring: the role of fixing the anti-wear tile to avoid problems such as the anti-wear tile falling off during installation.

The types of common anti-wear tile rings can be divided into: U-shaped lap type snap ring, butt-type semicircular snap ring.

All products are purchased to proprietary customized specifications as well as normal industry standards with supporting documentation.

The inner diameter of the U-shaped snap ring is the outer diameter of the wear-resistant tile plus the thickness of the wear-resistant tile, and the length varies from 20mm to 70mm. It will be 5mm more in semicircle. The extra part during installation will hold the wear-resistant tile and then spot weld. Compared with the butt-type semicircular snap ring...

C-shaped snap ring is the most common snap ring. Mainly based on the size of anti-friction tile, the diameter and thickness are similar to the matching anti-friction tile, and the length varies from 20mm to 70mm. It is mainly connected to the wear-resistant tile by spot welding when installing the wear-resistant tile, so as to fix and prevent the wear-resistant tile from falling off.

Custom snap rings are the recommended method for tube shield attachment.

Different types of stainless steel are selected according to the specific conditions of different working conditions.

The boiler was originally designed to be accurate. Different materials have different temperature resistance and mechanical strength, generally has a temperature resistance of 600 ℃ or less.

We can also supply boiler tubes erosion shields of other materials.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.