Erosion Shields

Erosion Shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

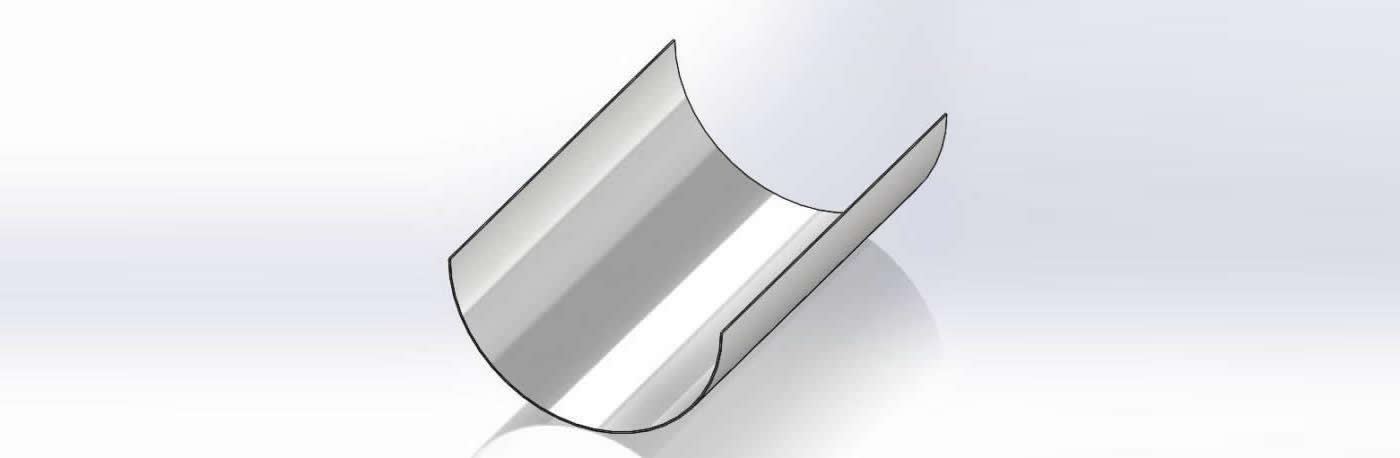

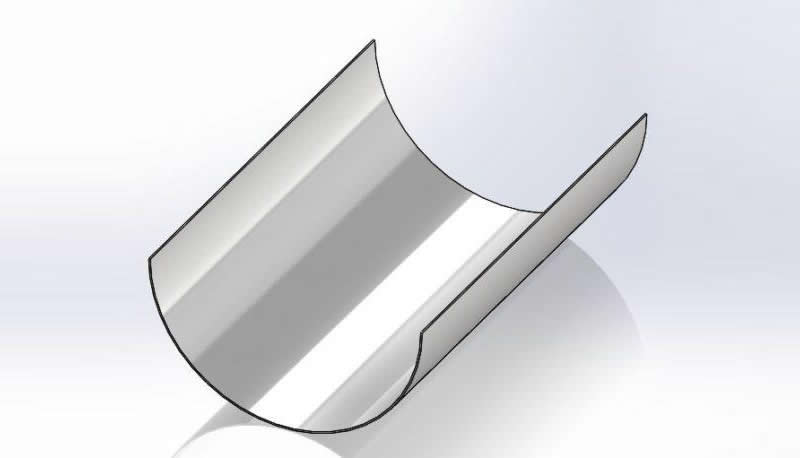

Half round anti-corrosion and anti-wear protection shields for boiler tube is a common component of the heating part of tubes.

Download PDFHalf Round Anti-Corrosion and Anti-Wear Protection Shields are essential components used in boiler systems to protect boiler tubes from harsh operating conditions. These shields, also known as boiler tube shields, are designed to enhance the longevity and performance of boiler tubes by offering protection against corrosion, wear, and erosion.

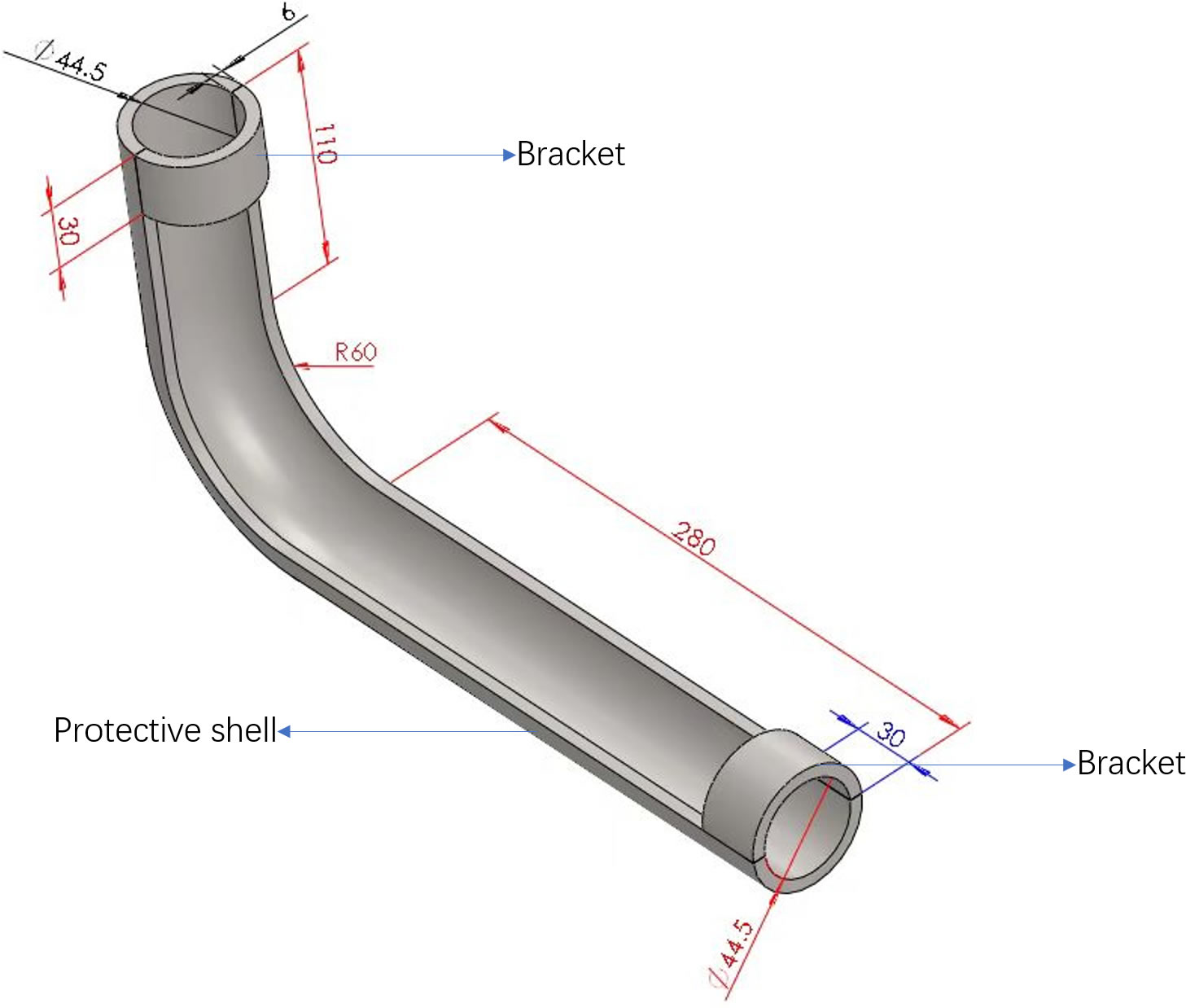

The useful life of tube shield is 3-5years. The tube shield has a variety of material and the selection of the material shall be subject to the original design of the boiler.The tube shield is divided into straight pipe and bend pipe.

The main effect of tube shield is to protect the pipe and increase the service life of the pipe. Boiler tube shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

Half Round Anti-Corrosion and Anti-Wear Protection Shields are indispensable for maintaining the integrity and efficiency of boiler tubes in various industrial applications. By providing robust protection against the harsh conditions found in boilers, these shields ensure reliable operation, reduce maintenance costs, and extend the lifespan of critical boiler components. Whether in power plants, petrochemical facilities, or industrial boilers, these protection shields offer a cost-effective solution for safeguarding boiler tubes from corrosion and wear.

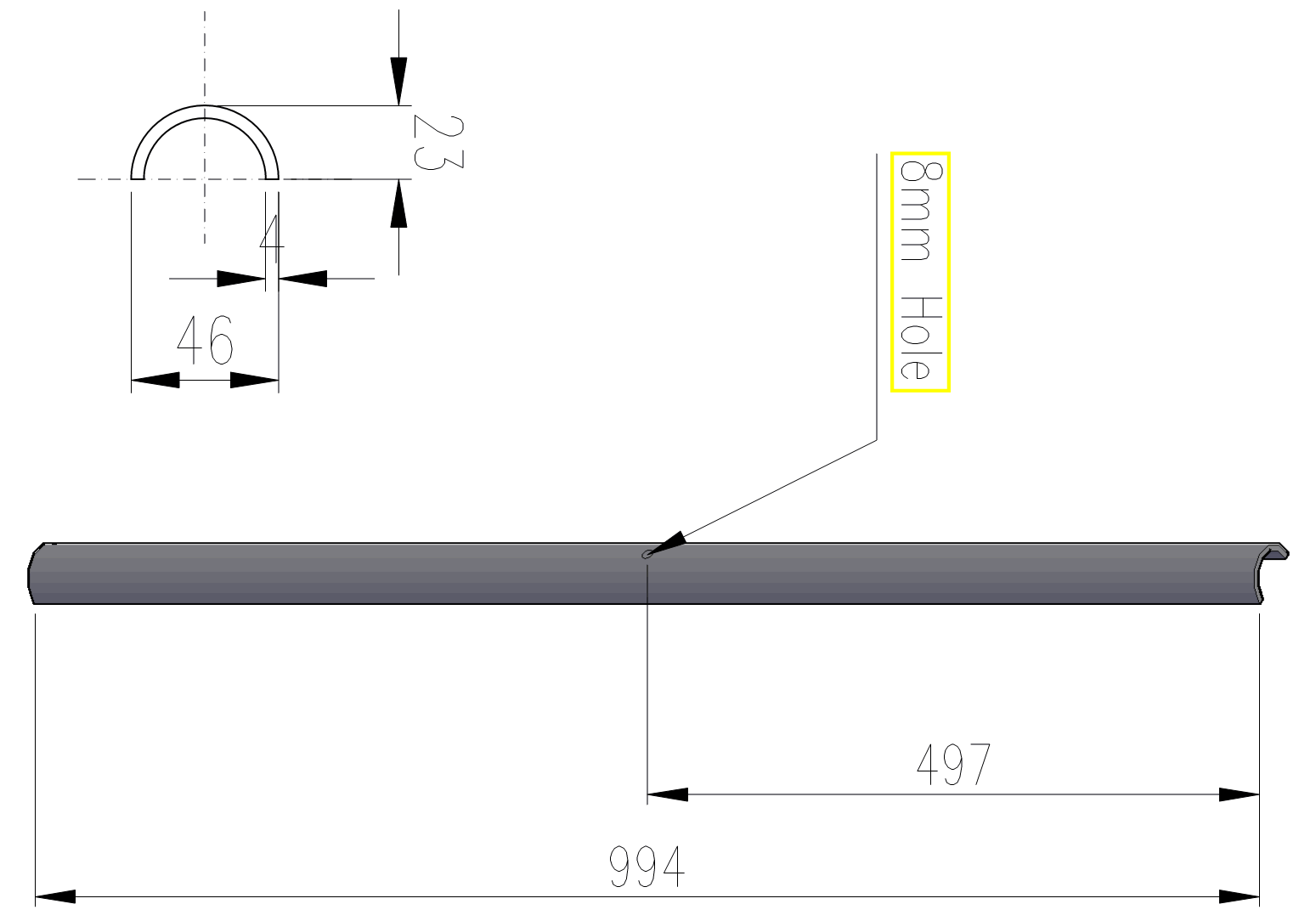

A half-round long shield typically refers to a protective cover or guard that is shaped in a half-round (or semi-circular) form. This kind of shield is often used in various industrial applications to protect pipes, tubes, and other cylindrical components from wear, impact, or corrosion. The "long" aspect indicates that the shield covers a significant portion of the length of the component it is protecting.

Half round long shield cover plate as per drawing, Drawing no: DWG-015/20223, Material: SS310, Size: Length 994mm, Thickness 4mm, Half round outer Dia 46mm, and center of the shield 8mm one hole. High Temperature Superheater anti abrasive cover for Convertive Pass,

Different types of stainless steel are selected according to the specific conditions of different working conditions.

The boiler was originally designed to be accurate. Different materials have different temperature resistance and mechanical strength, generally has a temperature resistance of 600 ℃ or less.

We can also supply boiler tubes erosion shields of other materials.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

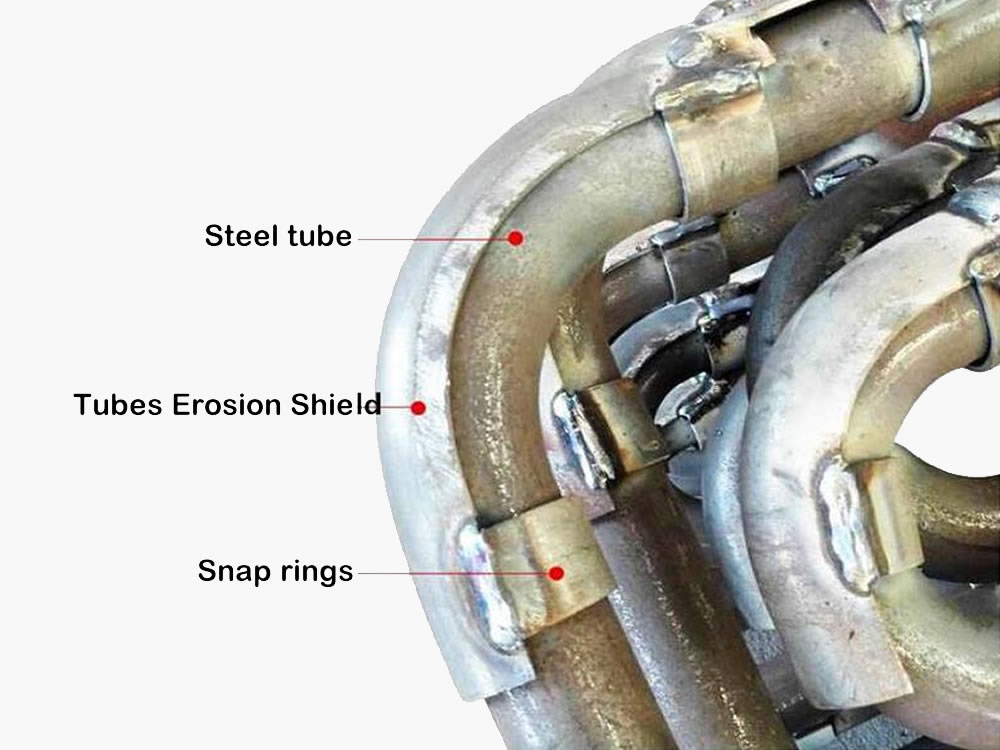

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.