ASTM A192 Boiler Tubes

Seamless carbon steel boiler tubes ASTM A192, designed for high-pressure steam service.

Coal steam boiler tube erosion shields are essential for economizers in power station boilers, offering 3-5 years of service life. They protect heating tubes from wear, extending boiler efficiency and durability.

Download PDFAn erosion shield is a protective covering applied to the surfaces of boiler tubes, especially in areas exposed to high-velocity flue gases and abrasive particles. In coal steam boilers, economizer tubes are particularly susceptible to erosion due to the combination of high temperatures and particle-laden gases. By installing an erosion shield, the wear on these tubes is significantly reduced, enhancing the overall efficiency and reliability of the boiler.

Erosion shields are used to protect boiler tubes from erosion caused by flue gases coming into contact with the bends of the tubes.

Erosion shields can be installed selectively in areas that are prone to tube leakage.

Erosion shields can protect the boiler's heating surface, such as the economizer, and extend the service life of the boiler.

Austenitic stainless steel tube shields are often used to reduce fuel ash corrosion in corrosive boiler locations. Materials with higher chromium concentrations, generally greater than 20%, have lower fuel ash corrosion rates.

The Coal Steam Boiler Tubes Erosion Shield for Economizer is a critical solution for industries looking to protect their boiler tubes from the damaging effects of erosion. By investing in erosion shields, facilities can increase the durability of their economizer tubes, improve the overall efficiency of their steam boilers, and significantly reduce maintenance costs. This practical and cost-effective solution ensures that boilers run smoothly and efficiently for extended periods, with less downtime and fewer failures.

Coal steam boiler tubes erosion shield used for economizer is a common component of the heating part of tubes.It is usually used in power station boilers.The useful life of tube shield is 3-5years.The tube shield has a variety of material and the selection of the material shall be subject to the original design of the boiler.The tube shield is divided into straight pipe and bend pipe.The main effect of tube shield is to protect the pipe and increase the service life of the pipe. Boiler tube shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

Boiler tubes are metal tubes that heat water to produce steam. They are commonly made of carbon steel or alloy steel and are used in a variety of applications, including power generation, fossil fuel plants, and industrial processing plants.

Sunny Steel has an extensive range of boiler and stay tubes available to meet your boiler tube requirements no matter how demanding.

Chinese National standards

American society of mechanical engineers

American Society for Testing and Materials

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services.

Deutsche industrie normen

Deutsche industrie normen

Japanese industrial standards

The SA 213 Tp 304 Material consists of 18% chromium and carbon, manganese, phosphorus, sulfur, silicon and nickel in the composition.

SA213 TP304 is a range of minimum wall thickness pipe series. We supply the SA 213 TP 304 Pipes in different types, shapes and sizes. The SA 213 Tp 304 Material consists of 18% chromium and carbon, manganese, phosphorus, sulfur, silicon and nickel in the composition. There is also the molybdenum, nitrogen, niobium and titanium addition in trace quantities. The SA 213 Tp 304 Density is lower than the ordinary 304 material. It is 7.8 grams per cubic centimeter. We offer ASTM A213 TP 304 for high temperature services. Our 304 Stainless Steel Tube components are of less absolute roughness which means they could be used in high precision equipment and applications.

Austenitic stainless steels are presented in the ASME Boiler and Pressure Vessel Code with two sets of allowable stresses. The reason for this is their relatively low yield strength. The higher allowable stress values were determined at temperatures where the usage would be restricted by the short-time tensile properties.

The higher stresses exceed 62-1/2%, but do not exceed 90% of the yield strength. At these stresses, small amounts of plastic deformation can be expected. These higher stress values are usually used for super-heater and reheater tubing.

The Boiler Code lists maximum allowable stresses for varying temperatures depending on the individual austenitic stainless grade.

Variations of this 18 chromium, 8 nickel grade include 304L, 304LN, 304H and 304N. Each of these offers excellent corrosion and oxidation resistance along with high strength.

High strengths are maintained in the low carbon grades by controlling the nitrogen content.

T304 has higher carbon and a minimum solution annealing temperature to assure good long-time elevated temperature strengths. T304 grades are limited to 1650F under oxidizing conditions. Section I of the ASME Boiler Code lists allowable stresses up to 1500F.

SA213 TP316 Tube is a material standard for heat exchanger tubes that are made from 316 austenitic stainless steel.

The chromium nickel alloy also has molybdenum in its composition which makes it more corrosion resistant and heat resistant than the 304 material. ASME SA213 TP316 is the second most used pipe material in the world next to the 304 material. ASTM A213 TP316 Tube is an austenitic stainless steel but the 213 standard covers both the austenitic and ferritic steels.

Sunny Steel is a supplier of ASTM A213 Grade TP316 products in different standards and sizes. Our 316 Stainless Steel Tube can come with different finishing such as the 316 Stainless Steel Tubing Polished or electropolished. We also provide the pipes in different shapes such the round, rectangular or Stainless Steel 316 Square Tube. The square and 316 Stainless Steel Rectangular Tube is usually used in high pressure applications to withstand the pressure stress at change of directions. The Stainless Steel 316 Seamless Tube is more accurate in dimensions and therefore it is used in high precision applications. Our 316 Stainless Steel Exhaust Tubing is of high quality and can withstand high temperatures; it is used in exhausts, heat exchangers and super heaters. The 316 Stainless Steel Heavy Wall Tubing is used in high pressure applications such as hydraulic systems. Our SS 316 Welded Tube is easy to weld upon. We supply 316 Stainless Steel Welded Tube for affordable prices in different sizes and schedules. Please contact us for further details and pricing.

SA213 TP321 is a specification of heat exchanger tubes that are made from the 321 austenitic stainless steel.

SA213 TP321 is a specification of heat exchanger tubes that are made from the 321 austenitic stainless steel. The SA 213 specifies pipe products for heat exchangers in different material grades, both the ferritic and austenitic steels.

Sunny Steel is a supplier of all kinds of stainless steel pipes. The SA213 Tp321 Material is special in that the composition includes titanium which reduces the density of the ASME SA213 Tp321 and therefore making it lightweight.

T321 and 347 are variations of T304 and have comparable minimum tensile properties. These two grades are stabilized with additions of titanium and columbian respectively, along with proper heat treatment.

To insure good long-time strength at elevated temperatures, T321H and 347H-like 304H-were developed with higher carbon contents and specified minimum solution annealing temperatures.

Of all the stainless steels, T309 (25 chromium, 13 nickel) and T310 (25 chromium, 20 nickel) offer the maximum resistance to oxidation and corrosion. They also offer good high-temperature properties. Since these steels contain ferrite, however, they are more susceptible to sigma phase.

The ends are vertical to the longitudinal axis and are without burrs.

| Tube OD | 26.7 - 114.3 mm |

|---|---|

| Tube WT | 3.2 - 12.5 mm |

| Tube lengths | 4 - 13 meters |

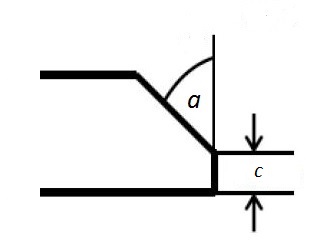

| Deburring angle, a | 30°+ 5 and 37°± 2.5 |

| Dimension, c | 1.6 ± 0.8 mm |

The tubes with deburred ends or ends customized for welding.

We have capability and capacity to ensure boiler tube in superior condition, with advanced inspection and testing procedures, standard tests include dimensional examination, visual checking, chemical composition, mechanical properties as well as non destructive test 100% eddy current test.

Fire-tube boiler is a type of boiler in which hot gas passes from the fire through one or more pipes that pass through a sealed water container. The heat of the gas is transferred through the wall of the tube through heat conduction, heating the water and eventually generating steam. Fire tube boilers are the third of the four historical types of boilers: low-pressure tank or “haystack” boilers, flue boilers with one or two large flues, fire tube boilers and high-pressure boilers with many small tubes

Water tube boiler is a type of boiler in which water circulates in tubes heated externally by the fire. The fuel is burned in the furnace to produce hot gas, which heats the water in the steam generation tube. In smaller boilers, the additional power generation tubes are separated in the furnace, while larger utility boilers rely on water injection tubes that make up the furnace wall to generate steam. High-pressure water tube boiler: The hot water then rises into the steam drum. Here, saturated steam is drawn away from the top of the drum.

Boiler Tubes are metal tubes located inside of boilers that heat water in order to produce steam.

There are two major types of tube boilers: water-tube boilers and fire-tube boilers. In water-tube boilers, water circulates inside the tubes and is heated externally by hot gases generated by the furnace. Boiler tube is installed inside boiler to heat water in order to generate steam, boiler is a closed pressure vessel designed in varieties of types, water tube boiler and fire tube boiler are main types.

| Steel Grade | Standard | Application | ||

|---|---|---|---|---|

| GB(China) | ASME(USA) | DIN/EN(Euro) | ||

| Carbon steel | 10 20 20G 20MnG 25MnG |

SA-106B SA-192 SA-210A1 SA106C SA-210C |

PH265GH P195GH P235GH St35.8 St45.8 |

Economizer tube Water wall tube |

| Mo steel | 15MoG 20MoG |

SA-209 T1 SA-209 T1a SA-209 T1b |

15Mo3 16Mo3 |

Water wall tube Superheater tube Reheater tube |

| Cr-Mo Steel | 12CrMoG 12Cr2MoG 12Cr1MoVG 15CrMoG 10Cr9MoVNb |

SA-213 T11 SA-213 T22 SA-213 T24 SA-213 T91 A335 P1 A335 P2 A335 P5 A335P9 A335 P11 |

12Cr1MoV 14MoV63 10CrMo910 X10CrMoVNb91 10CrMo5-5, 13CrMo4-5 |

Superheater tube Reheater tube |

| Cr-Mo-W steel | 12Cr2MoWVTiB | SA-213 T23 SA-214 T911 SA-213 T92 SA-213 T122 A335 P23 A335 P911 A335 P92 A335 P122 |

--- | Superheater tube Reheater tube |

| Austentic Stainless steel | --- | AP304 TP304H TP321 TP321H TP347 TP347H TP316 TP316H S30432 TP310HCbN |

--- | Superheater tube Reheater tube |

Boiler tubes are used in fire-tube boiler, a type of boiler in which hot gases from a fire pass through one or more tubes running through a sealed container of water.

How to get rid of surface stains of cracking tube follow the steps below:

The first step is to clean, we must first petroleum cracking tube surface oil, dirt, grease, and some other substances removed. The second step is naturally acid, generally speaking, there are two pickling treatment, a chemical treatment, another treatment method is electrolysis, which can be handled in two ways petroleum cracking tube surface cleaning clean, but chemical pickling is a pipeline anti-corrosion measures.

The third step is necessary to use the tool to the surface of the oil cracking pipe polished, although the effect may not be very good polish, but this procedure is also indispensable. The final step is to make the surface of petroleum cracking tube jet, one can remove some of the dirt, the second is to make the roughness of petroleum cracking tube more evenly.

For petroleum cracking tube defects formed on the surface there are many, but certainly there are a lot of different reasons, the specific form of the crack is different, often found defective for its appearance on petroleum cracking tube we can see, the main reason for its main form by the following points. In fact, for the production process, the emergence of various drying phenomena of its raw materials for steelmaking summer rainy season or when it will produce up to steel gas content's sake.

In the process, the ingot when heated due to heating of the air bubbles are burned through, it will have more cracks after the rolling, which will meet the petroleum cracking tube relatively thin, dense and sizes, its length ranging from cracks, these things collectively referred to as hairline, this is a defect. So the cause of the surface oil cracking tube defects are many, so we have to remedy. After oil cracking pipe handling, appearance becomes smoother, more beautiful. Although after the rust will not affect the use again, but if we do the work in advance, so do not bother it. We buy petroleum cracking tube among the first to note that it is not a strong corrosion resistance, have a longer life does not have to select a high-quality petroleum cracking pipe products that can reduce our future work a lot of trouble.

Small diameter high-pressure boiler tube surface defects that affect the quality, mainly due to waste generation.

Boiler pipes often in high temperature and high pressure work, pipe smoke and water at high temperature steam oxidation and corrosion effects will occur, thus requiring durable steel with high strength, high oxidation resistance, and good organizational stability, high pressure boiler tube in addition to chemical composition and mechanical properties, hydrostatic testing done by the root, to be flaring, flattening test. Steel to heat treatment delivery. In addition, the finished steel microstructure, grain size, there are certain requirements decarburization.

High-pressure boiler tubes are seamless steel pipe categories. Seamless same manufacturing method, but used in the manufacture of steel pipe, there are strict requirements. Often in high-pressure boiler tubes at high temperature and pressure conditions of use, the tube under the effect of high temperature gas and water vapor, oxidation and corrosion will occur. Require durable steel with high strength, high resistance to oxidation corrosion, and have good organizational stability.

High-pressure boiler tube is mainly used to manufacture high-pressure and high pressure boiler superheater tubes, reheater tubes, windpipe, the main steam pipe. High-pressure boiler tubes for low and medium pressure boiler (working pressure is generally not more than 5.88Mpa, working temperature below 450 ℃) of heating surface tubes; used for high-pressure boilers (above 9.8Mpa working pressure in general, the working temperature of 450 ℃ ~ 650 ℃ between) the heating surface tubes, economizer, superheater, reheater, petrochemical industrial pipe.

High pressure boiler tube hardness testing should take into account its mechanical properties, which is related to stainless steel as raw material for the deformation, such as punching, cutting processing performance and quality.

Therefore, all of the high-pressure boiler tubes need to conduct mechanical tests. Mechanical performance testing method is mainly divided into two kinds, one kind is tensile test, the other kind is usually hardness test.

Tensile test is the high pressure boiler tube sample, high pressure boiler tube tend to sample to the fracture on tensile testing machine, mechanical properties and determination of one or more, usually only determination of tensile strength, yield strength, break elongation, and reduction of area. Tensile test is the most basic mechanical properties of metallic materials testing methods, almost all of the metal material, as long as the requirements of the mechanical properties of the high pressure boiler tube, the provisions of the tensile test. Especially those appearance and high pressure boiler tube is not good for the material of hardness test, tensile test became the only means of mechanical properties testing.

A steam boiler is a device used to create steam by applying heat energy to water.

A continuous helical fin is attached to the base tube by high frequency electric resistance welding in order to give an efficient and thermally reliable bond. Fins can be either solid or serrated (segmented). The weld produced in this process is a true forge, blacksmith weld. This type of weld is comprised of a fusion between two portions of parent metal without the introduction of a filler material. The weld is simply produced by heating the interfaces to be joined to a plastic state and applying pressure.

Used in boilers, furnaces and fired heaters for efficient heat recovery.

High-pressure boiler tubes are frequently occurs fault because of high temperatures, affecting the entire heating system, mainly due to an internal boiler for heat treatment is not perfect, a lot of heat can not be effectively converted and timely treatment.

High pressure boiler tube hardness testing should take into account its mechanical properties, which is related to stainless steel as raw material for the deformation, such as punching, cutting processing performance and quality.

Therefore, all of the high-pressure boiler tubes need to conduct mechanical tests. Mechanical performance testing method is mainly divided into two kinds, one kind is tensile test, the other kind is usually hardness test.

Finned tubes are used in applications involving the transfer of heat from a hot fluid to a colder fluid through a tube wall.

The rate at which such heat transfer can occur depends on three factors:

a. Cleaning

Using the solvent and emulsion to clean the surface of high pressure boiler pipe, so as to achieve the purpose of removing oil, grease, dust, lubricant and similar organic matter. But it cannot remove the dust, oxide skin, welding medicine and so on. So it is only as a supplementary method in the anti-corrosion production.

b. Tool

Tool rust removal mainly use wire brush and other tools to grind the surface of high pressure boiler pipe. It can remove loose or warping of the oxide skin, rust, welding slag and so on. Manual tool can reach SA2 level, power tool can reach SA3 level. If the iron oxide scale attached to the surface, it cannot reach the anchorage depth required by the anti-corrosion construction.

c. Acid cleaning

High pressure boiler pipe generally adopt chemical and electrolytic methods to do pickling treatment.

d. Spray rust removal

Spray rust removal cannot only remove rust, oxide and dirt completely, but also high pressure boiler pipe can achieve the required uniform roughness under the action of abrasive impact and friction force.

Spay rust removal cannot only expand the physical adsorption on the surface of high pressure boiler pipe, but also enhance the mechanical adhesion between the anti corrosion layer and the pipe surface. So spray rust removal is ideal method of rust removing for pipeline corrosion.

Boiler pipe forming include fin tube, serpentine tube and reaming welding.

Boiler tubes need take for a variety of molding in the boiler manufacture and installation process

Heat treatment is a method of changing the physical properties of high pressure boiler pipe by heating and cooling. Heat treatment can improve the microstructure of high pressure boiler pipe, so as to meet the required physical requirements. Toughness, hardness and wear resistance are obtained by heat treatment. In order to obtain these characteristics, it is necessary to adopt quenching, annealing, tempering and surface hardening.

a. Quenching

Hardening, also called quenching, is that high pressure boiler pipe is heated evenly to the appropriate temperature, then quickly immerse in water or oil for rapid cooling, and cooling in the air or in the freezing zone. So that the high pressure boiler pipe can obtain the required hardness.

b. Tempering

High pressure boiler pipe will become brittle after hardening. And the stress caused by quenching can make the high pressure boiler pipe tapped and broken. The tempering method can be used to eliminate brittleness. Although the hardness of high pressure boiler pipe is lighter reduced, its the toughness can be increased to reduce the brittleness.

c. Annealing

Annealing is the method to eliminate the internal stress of high pressure boiler pipe. The annealing method is that the steel parts need to be heated to the critical temperature, then put in dry ash, lime, asbestos or closed in the furnace, then let it cooling slowly.

| Material | Standard | Material |

|---|---|---|

| Stainless Steel | ASTM | 201, 202, 301, 304, 304L, 304N, XM21, 304LN, 305, 309S, 310S, 316, 316Ti, 316L, 316N, 316LN, 317, 317L, 321, 347, 329, 405, 409, 430, 434, 444, 403, 410, 420, 440A, etc. |

| EN | 1.4372, 1.4373, 1.4319, 1.4301, 1.4306, 1.4315, 1.4303, 1.4833, 1.4845, 1.4401, 1.4571, 1.4404, 1.4429, 1.4438, 1.4541, 1.4550, 1.4477, 1.4462, 1.4002, 1.4512, 1.4016, 1.4113, 1.4509, 1.4521, 1.4006, 1.4021, 1.4028, etc. | |

| JIS | SUS201, SUS202, SUS301, SUS304, SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS305, SUS309S, SUS310S, SUS316, SUS316L, SUS316TI, SUS316N, SUS316LN, SUS316J1, SUS316J1L, SUS317, SUS317L, SUS321, SUS347, SUS329J1, SUS329J3L, SUS405, SUH409, SUS410L, SUS430, SUS434, SUS444, SUS403, SUS410, SUS420J1, SUS420J2, SUS440A, SUS440B, SUS440C, etc. |

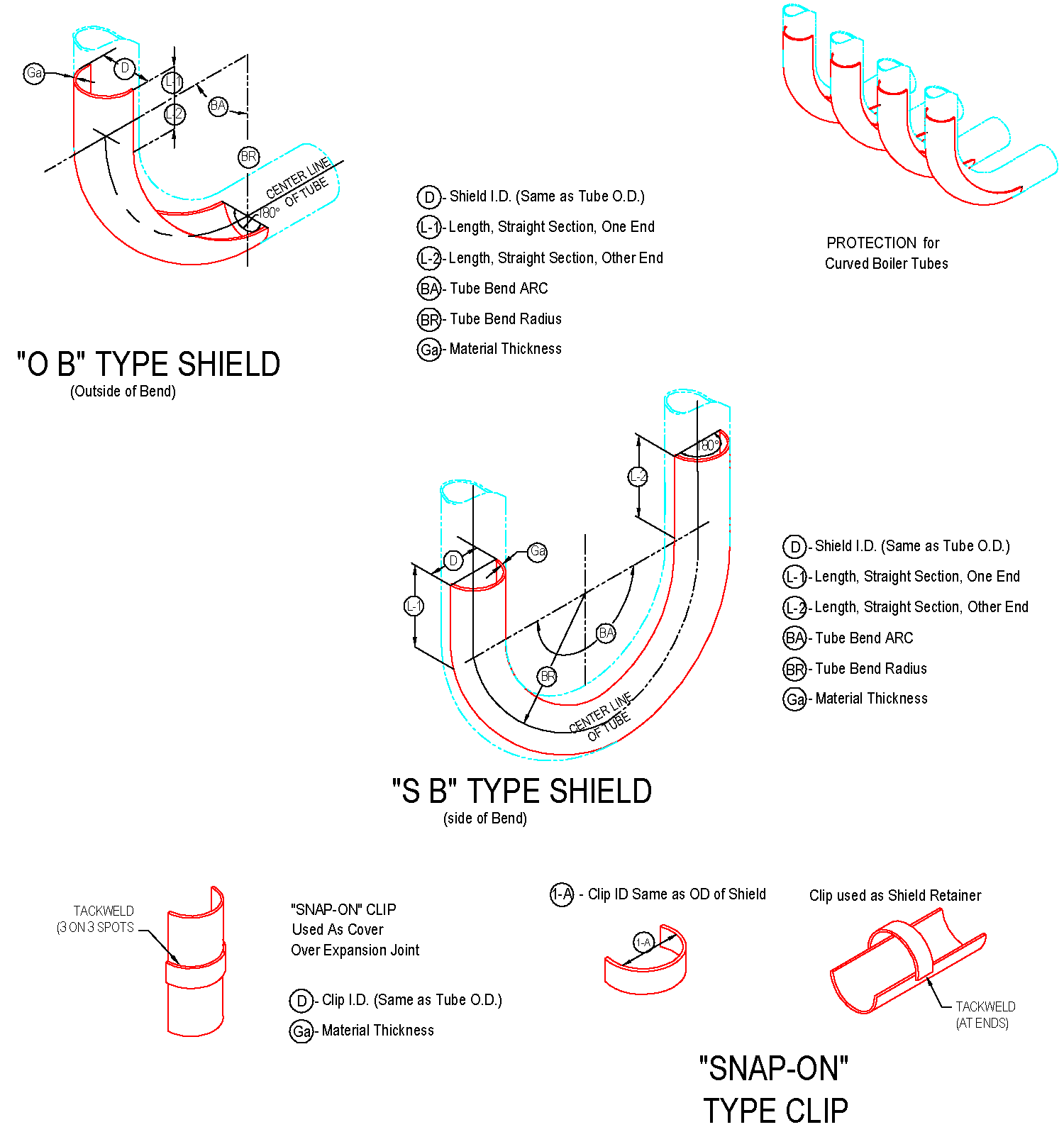

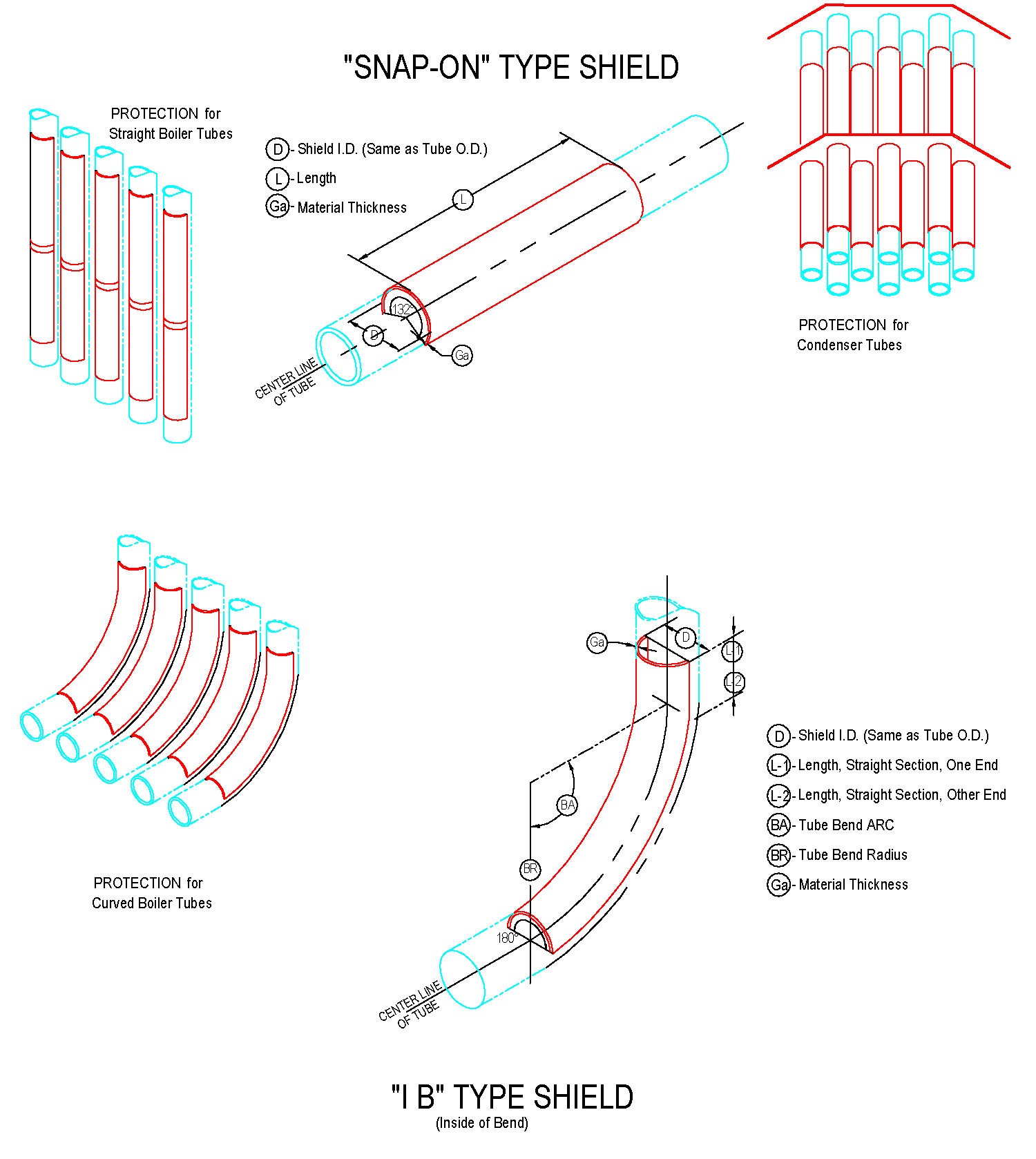

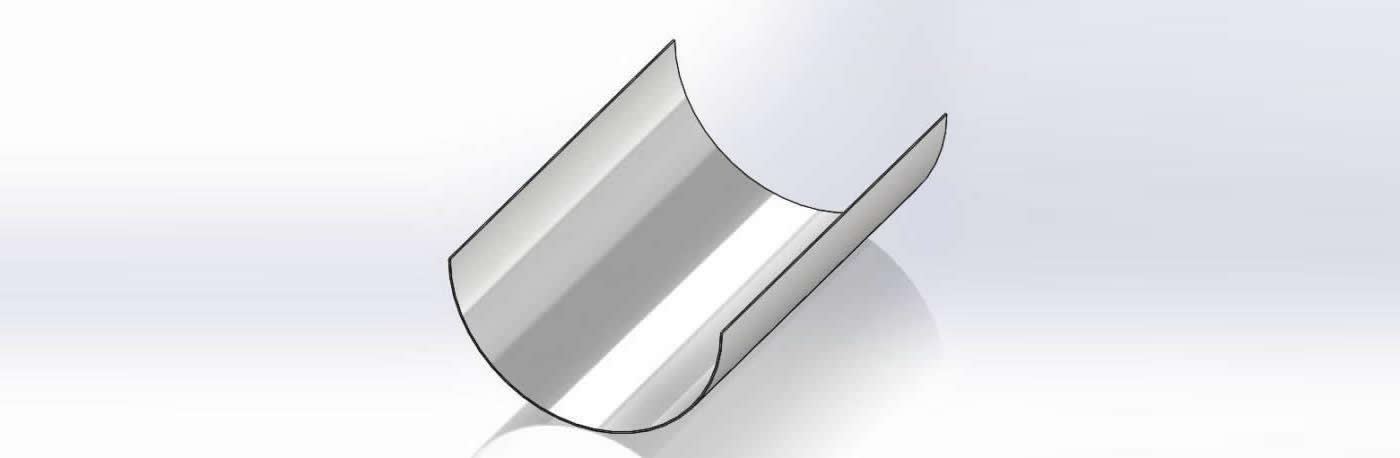

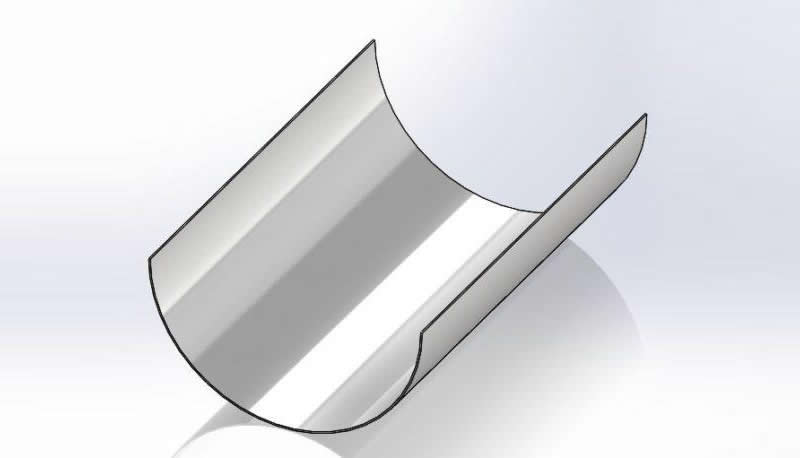

The cross-sectional shape of boiler tubes shields is mostly semi-circular (180 degrees), and there are also 120-160 degrees.

It is mainly used on finned tubes (water-cooled walls); boiler tube erosion shields are divided into direct wear-resistant shields, in-curve, anti-wear shields, outer-curve, anti-wear shields, side-curve anti-wear shields, s-curve anti-wear shields, etc.

The length of the straight anti-wear shields ranges from 20mm to 3000mm, and the general length of 1000-2000mm is commonly used. The anti-wear shields with bends generally requires a processing drawing and the following parameters should be on the drawing: outer diameter of the pipe used, bending of the pipe Radius R (to the center of the pipe), the degree of bending angle, and the length of the straight sections on both sides of the arc segment of the wear-resistant shields.

The most basic parameter of boiler tubes shields is the outer diameter of the tube used (that is, the inner diameter of boiler tubes erosion shields). The main specifications of the tube are: 32, 38, 42, 44.5, 48, 51, 57, 60, 63.5 , 76, 89mm, etc . the inner diameter of the boiler tubes erosion shields is usually 1-3mm larger than the outer diameter of the tube used, depending on the actual requirements.

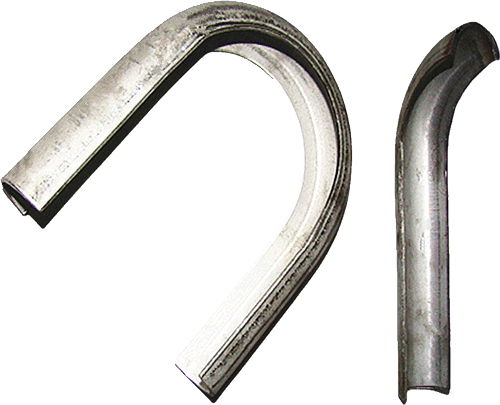

The current production process for tube shields is to use high-pressure presses and professional moulds for pressing.

Tube shields from us are manufactured to exacting standards. Advanced equipment and material handling capabilities permit us to offer the fastest turnaround times anywhere.

The current production process for tube shields is to use high-pressure presses and professional moulds for pressing.

The production time is short, the welding performance is good, the welding seam does not fall off, the surface is smooth and the appearance is beautiful. The arc-shaped wear-resistant tile is pressed on a press or bent on a pipe bender with a special mould.

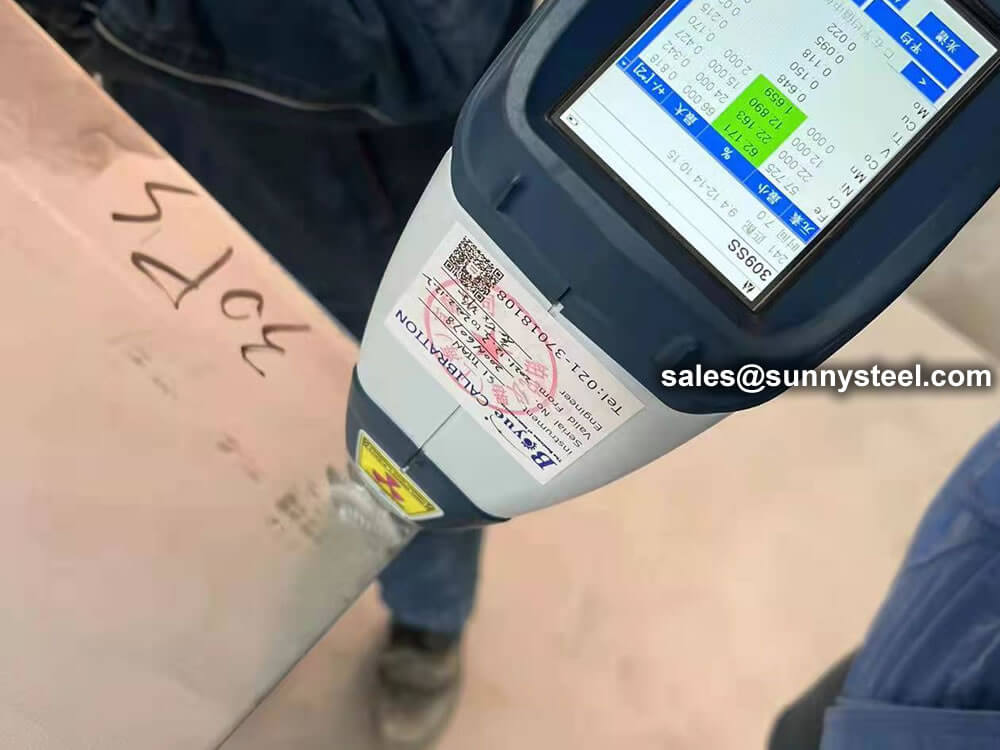

To ensure the accuracy of the material. Positive Material Identification (PMI) of stainless steel sheets for tube shields is critical to verifying the grade and composition of stainless steel before it goes into production.

The raw materials for the production of tube shields are generally purchased directly from standard steel mills, and each batch has an MTC. Due to the sharpe limitations of raw materials, it is inevitable that excess materials will be produced. We can use the excess material to make a smaller size snap ring.

Different types of stainless steel are selected according to the specific conditions of different working conditions.

The boiler was originally designed to be accurate. Different materials have different temperature resistance and mechanical strength, generally has a temperature resistance of 600 ℃ or less.

We can also supply boiler tubes erosion shields of other materials.

Tube shields are custom made to fit perfectly to straight sections, curved sections and even finned and specialised tubing.

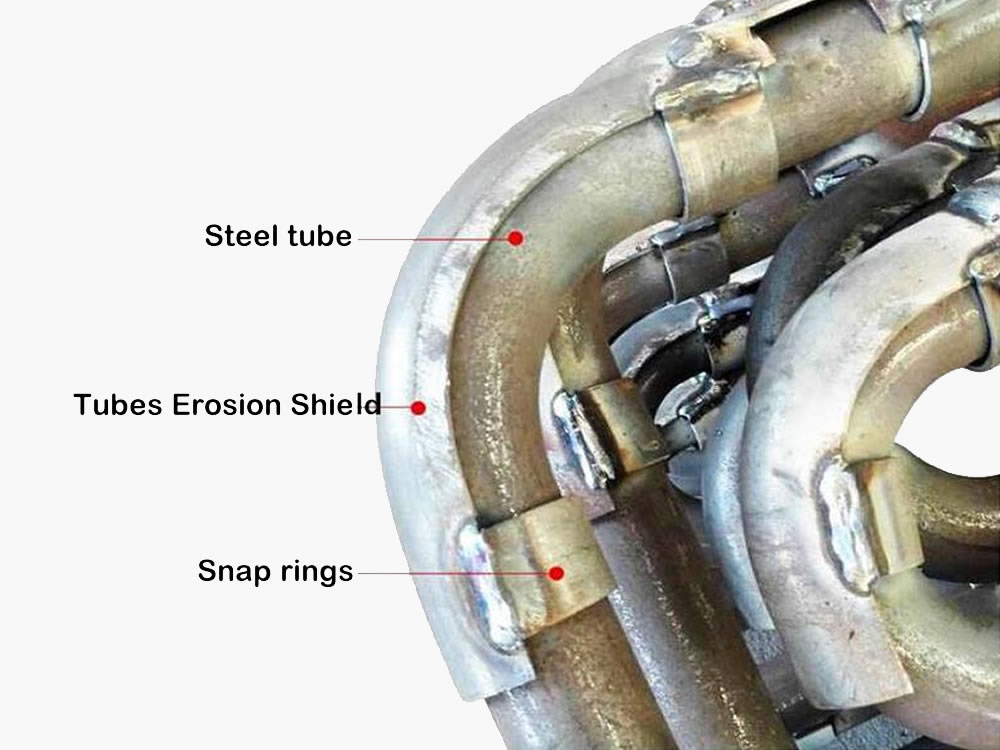

Boiler tube erosion shields, also known as anti-corrosion shields, anti-wear plate, anti-wear protection shields, anti-wear cover plate, anti-corrosion cover plate, boiler climbing pipe, anti-wear pressure plate, etc. , which are used in combination with snap rings.

Boiler tube erosion shields are produced using a high-pressure press and professional mould pressing. The production time is short, the welding performance is good, the welding should not fall off, the surface is smooth, and the appearance is beautiful. Boiler tube erosion shields with bends are formed by pressing on a press or bending with a special abrasive on a tube bender.

Boiler tube shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

The service life of boiler tubes erosion shields is different in different types of boilers and different use parts.

The normal service life is a period of overhaul (3-5 years) for the boiler. Generally, some boilers will be replaced or retrofitted every time the boiler is overhauled. The main replacements are those of the Boiler Tubes Erosion Shields that are severely thinned and exceeded the standard; those that were not firmly detached during the boiler operation during the previous installation. According to the wear of the Boiler Tubes Erosion Shields during replacement, if the thickness is severely reduced, it needs to be replaced, the deformation is severe, and those that cannot protect the tube also need to be replaced. In addition, some boiler tubes are not equipped with Boiler Tubes Erosion Shields, but during the boiler inspection, it is found that the tubes have a tendency of wear and thinning. Generally, Boiler Tubes Erosion Shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

On the heating surface of superheater and economizer tube bundle of the boiler, in order to prevent the pipe from being worn by high temperature flue gas washing, boiler tubes erosion shields are mostly arranged on the outer side of the pipe in the direction of flue gas flow. The elbow erosion shields solves the abrasion problems of water wall tubes, superheater tubes, economizer tubes and reheater tubes in the furnace, and provides guarantee for the long-term and reliable operation of CFB boiler. With the increase of CFB boiler products, the type and quantity of The elbow erosion shields will increase.

Our understanding of and commitment to the steam and power generation business enables us to solve your boiler tube erosion or corrosion problems efficiently. Our technical staff can quickly recommend the proper material type and configuration to meet your needs…and can quote your outage delivery requirements on a month basis.

Do you accept a special order?

A: Yes, we do. We can manufacture all kinds of chemical equipments according to your technical drawings(Before you givethem to us, will sign the contract and confidentiality agreement with you. You don’t need to worry about that.)

Can you make a design for us?

A: Yes, we can. What we supply is not only product, but also solution and design. And if you make the product in our factory,the design will be free. If not, design fees will be charged accordingly.

Q: Do you provide after-sales service?

A: Yes, we do. This product is guaranteed up to one year from purchase unless manmade damage. If there is anything wrongwith product itself quality problem,we will change or repair it at our charge.If not, we will provide aftersales service at your charge.

Tube erosion shields are mainly used on the windward side of the heating surface of the boiler, such as superheaters, reheaters, economizers, and water-cooled wall pipes.

Erosion shields are used to protect boiler tubing from the highly erosive effects of high temperatures and pressures thereby greatly extending tube life.

We offer shielding for tubing, covering straight, bent and finned sections, as well as the clips that hold these in place.

In the long term, these shields more than pay for themselves, preventing the costly replacement of tubing and avoiding the downtime that results from tube breakdown and leaks.

In general, most of them are called “wear-resistant tile” and “wear-resistant cover plate”. Erosion Shields are special boiler accessories.

Generally, most of them are used in power station boilers, small boilers are used less, and some coal chemical industries will also use them.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.