Erosion Shields

Erosion Shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

High temperature corrosion resistant straight tube shields for boiler tube is a common component of the heating part of tubes.It is usually used in power station boilers.

Download PDFHigh-temperature corrosion-resistant straight tube shields are essential for protecting boiler tubes in industries that deal with extreme heat and corrosive environments. These shields provide a reliable solution to extend the lifespan of critical boiler components, reduce maintenance costs, and improve the overall efficiency and safety of industrial systems. Whether in power generation, waste incineration, petrochemical processing, or steel manufacturing, straight tube shields are vital for maintaining the integrity and performance of boiler systems.

Boilers, especially those used in power plants and industrial processes, operate under extreme conditions of heat and pressure. Protecting the tubes inside these boilers is critical for preventing corrosion, erosion, and mechanical damage. High-temperature corrosion-resistant straight tube shields are designed to protect boiler tubes from the harsh environments they face, ensuring longer service life and improved efficiency. This article highlights the importance of these shields, their features, and where they are used.

Straight tube shields are protective covers installed on boiler tubes to prevent wear and damage caused by high temperatures, corrosive gases, and particulates. These shields are typically made from high-performance alloys that provide excellent resistance to corrosion, erosion, and high-temperature oxidation. The shields help maintain the integrity of the boiler tubes by forming a durable protective barrier.

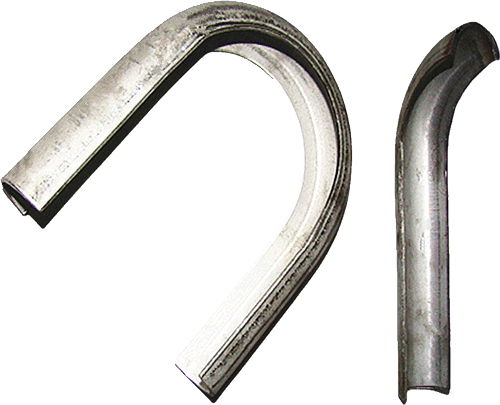

The useful life of tube shield is 3-5years. The tube shield has a variety of material and the selection of the material shall be subject to the original design of the boiler.The tube shield is divided into straight pipe and bend pipe.

It is usually used in power station boilers.The useful life of tube shield is 3-5years. The tube shield has a variety of material and the selection of the material shall be subject to the original design of the boiler.The tube shield is divided into straight pipe and bend pipe. The main effect of tube shield is to protect the pipe and increase the service life of the pipe.

The main effect of tube shield is to protect the pipe and increase the service life of the pipe. Boiler tube shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

| Material | Standard | Material |

|---|---|---|

| Stainless Steel | ASTM | 201, 202, 301, 304, 304L, 304N, XM21, 304LN, 305, 309S, 310S, 316, 316Ti, 316L, 316N, 316LN, 317, 317L, 321, 347, 329, 405, 409, 430, 434, 444, 403, 410, 420, 440A, etc. |

| EN | 1.4372, 1.4373, 1.4319, 1.4301, 1.4306, 1.4315, 1.4303, 1.4833, 1.4845, 1.4401, 1.4571, 1.4404, 1.4429, 1.4438, 1.4541, 1.4550, 1.4477, 1.4462, 1.4002, 1.4512, 1.4016, 1.4113, 1.4509, 1.4521, 1.4006, 1.4021, 1.4028, etc. | |

| JIS | SUS201, SUS202, SUS301, SUS304, SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS305, SUS309S, SUS310S, SUS316, SUS316L, SUS316TI, SUS316N, SUS316LN, SUS316J1, SUS316J1L, SUS317, SUS317L, SUS321, SUS347, SUS329J1, SUS329J3L, SUS405, SUH409, SUS410L, SUS430, SUS434, SUS444, SUS403, SUS410, SUS420J1, SUS420J2, SUS440A, SUS440B, SUS440C, etc. |

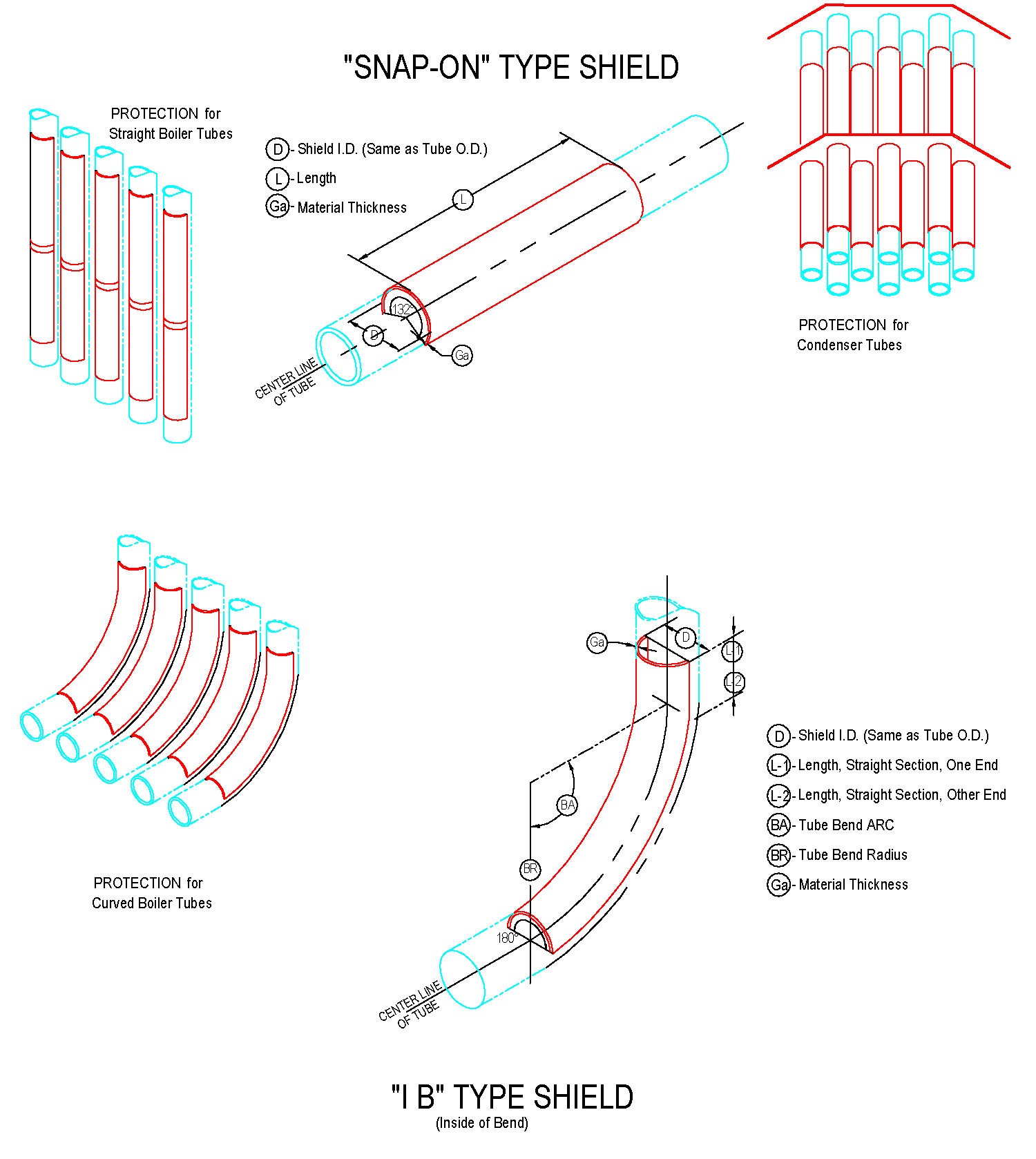

The cross-sectional shape of boiler tubes shields is mostly semi-circular (180 degrees), and there are also 120-160 degrees.

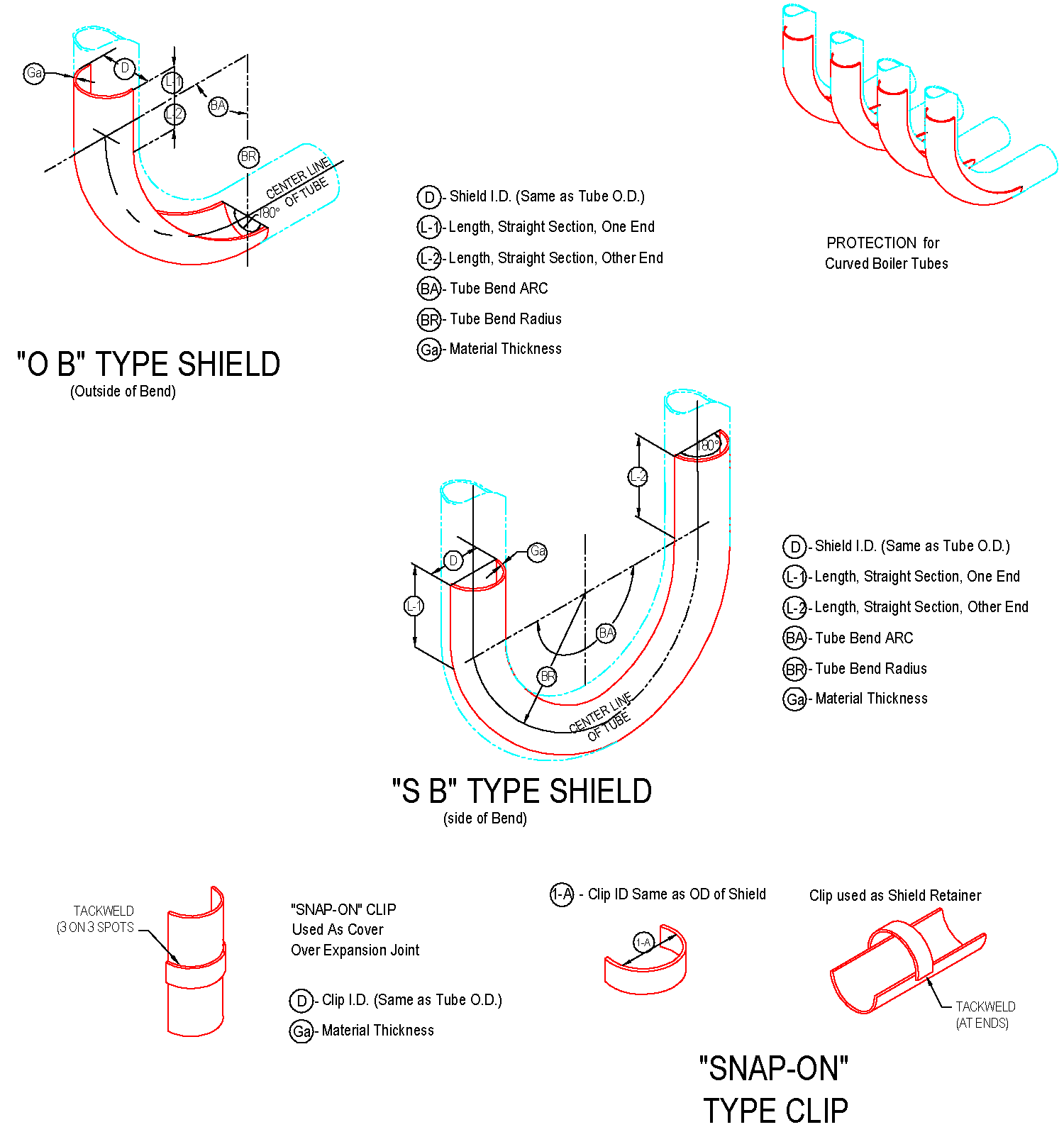

It is mainly used on finned tubes (water-cooled walls); boiler tube erosion shields are divided into direct wear-resistant shields, in-curve, anti-wear shields, outer-curve, anti-wear shields, side-curve anti-wear shields, s-curve anti-wear shields, etc.

The length of the straight anti-wear shields ranges from 20mm to 3000mm, and the general length of 1000-2000mm is commonly used. The anti-wear shields with bends generally requires a processing drawing and the following parameters should be on the drawing: outer diameter of the pipe used, bending of the pipe Radius R (to the center of the pipe), the degree of bending angle, and the length of the straight sections on both sides of the arc segment of the wear-resistant shields.

The most basic parameter of boiler tubes shields is the outer diameter of the tube used (that is, the inner diameter of boiler tubes erosion shields). The main specifications of the tube are: 32, 38, 42, 44.5, 48, 51, 57, 60, 63.5 , 76, 89mm, etc . the inner diameter of the boiler tubes erosion shields is usually 1-3mm larger than the outer diameter of the tube used, depending on the actual requirements.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.