Bearing Pipes

Pipes designed for bearing loads, offering high strength and durability.

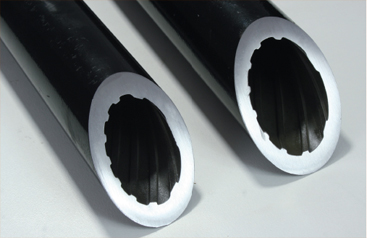

Multi-rifled seamless steel tubes are used in various applications, particularly in high-pressure boilers and heat exchangers.

Multi-rifled seamless steel tube is used as a water wall tube loaded with a highly heated flux and is also expected to find broadened other uses in the viewpoint of iits energy saving effect and higher safety against the overheating damage. This has groove on its inside surface which functions to raise thermal efficiency by distrubing the fluid within the tube, featuring and extremely high thermal conduction property.

The tubes may adhere to various standards, such as GB/T 20409, ASME SA-210M-2015, and ISO 9001. Compliance with these standards ensures the quality and performance of the tubes.

Rifled tubes used in furnace power plants and other facilities with high temperature and pressure that are used to prevent film boiling.

The rifled tube is used as a water wall tube loaded with a highly heated flux and is also expected to find broadened other uses in the viewpoint of its energy-saving effect and higher safety against overheating damage.

The rifled tube has a groove on its inside surface that functions to raise thermal efficiency by disturbing the fluid within the tube, featuring an extremely high thermal conduction property.

Inside the water wall pipes of boilers in sub-critical steam power plants, water boils into steam vapor. Inside high temperature/high pressure boiler devices, a special type of boiling called film boiling occurs. The boundary between the fluid and water wall pipe forms a layer of steam. When film boiling occurs, the heat transfer efficiency is reduced due to the steam layer. Since heat cannot be effectively transferred from the pipe to the water, the pipe temperature rise can cause boiling explosions due to overheating, resulting in facility damage. A rifled tube contains multiple butterfly ribs on the inner surface of the steel pipe, whisking the water inside and causing turbulence that suppresses film boiling. Multiple ribs greatly increase the internal surface area of the pipe compared to rib-less steel pipes, resulting in increased boiler energy output efficiency. Internally ribbed tubing helps to decrease mass flow and ensures sufficient cooling for the internal surfaces of tubes.

All our steel is melted in-house through electric arc furnace route, than is ladle refined, 100% vacuum degassed, continuous cast and rolled.

Rifled tubes are used in heat exchangers and boilers to provide highly energy efficient means of heat transfer. The presence of the internal rifling induces centrifugal forces in the mass flow thereby separating the water from the steam fraction and forcing the water towards the tube wall. As a result of this phenomenon and the increase in internal surface the following advantages accrue:

Rifle Tubes can be supplied against ASTM, ASME, A/SA 192, 209, 210 and 213 specifications and all associated grades.

Tubes can be supplied against equivalent specifications like EN 10216, DN 17175, BS 3059, JIS 3461, 3462.

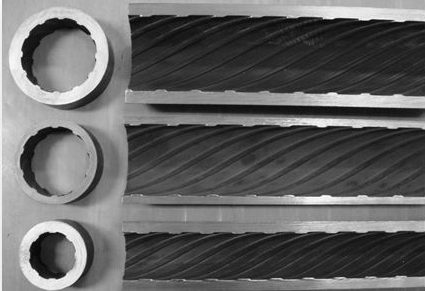

Tubes can be supplied to bath A and B type profiles. Detailed dimensions for each profile are given in the table.

As described above the heat transfer rate can be optimized by varying the rifling geometry based on operation conditions. In addition to the standard rifle tubes (covered in this brochure), SunnySteel manufactures rifled tubes to suit any customized geometry and in all boiler steel grades. We regularly manufacture and deliver such customized solutions at short notice.

Internally rifled boiler tubes are crucial for thermal power plants, where they help convert water into steam more efficiently. Their unique design, with internal spiral ribs, delays the boiling crisis, allowing for better heat transfer and preventing potential overheating. This makes them particularly valuable in subcritical and supercritical pressure boilers, though they come at a higher cost compared to plain tubes.

Internally rifled boiler tubes are characterized by their internally rifled shape, which features spiral ribs on the inner surface. This design is accomplished through a cold - drawing process, with a lead angle (spiral angle) of 30 degrees relative to the tube axis plane. The primary function is to boost heat transfer efficiency by deferring the boiling crisis. The boiling crisis is a situation where heat transfer becomes inefficient due to film boiling. By preventing film boiling and overheating, these tubes ensure safer and more efficient operation within high - pressure boiler systems.

The internal rifles generate turbulence and increase the internal surface area, which aids in maintaining nucleate boiling and eradicating the steam film that may form on the tube's inner surface. This is especially vital in subcritical and supercritical pressure boilers, where the operating conditions are extreme.

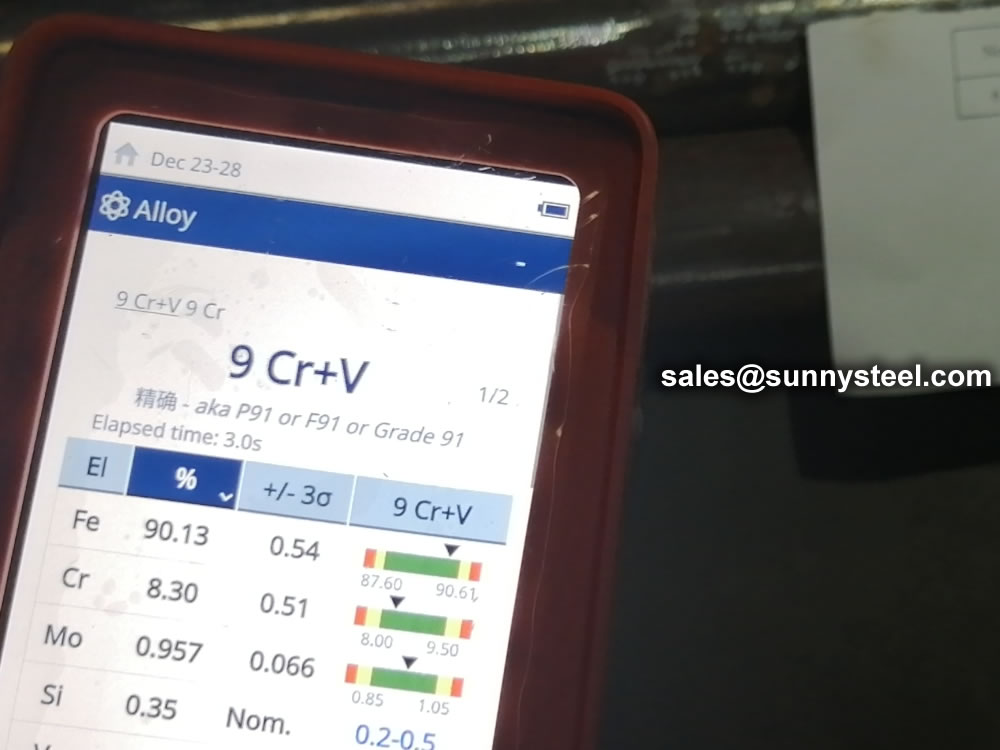

These tubes are typically fabricated from low - carbon steel or low - alloy steel. These materials are selected for their strength and heat resistance under high - pressure circumstances. The manufacturing process involves cold - drawing, which shapes the spiral ribs, ensuring precision and durability. Specific steel grades mentioned in relevant literature include 20G, SA210C, SA210A1, 15CrMoG, 12Cr1MoVG, T2, T12, T23, and T91, depending on the application and standards.

Internally rifled boiler tubes adhere to a variety of international standards to guarantee quality and safety. These include ASTM A192, ASME SA192, ASTM A209, ASME SA210, ASME SA213, EN 10216, DN 17175, BS 3059, JIS 3461, and JIS 3462, among others. For internally multi - lead rifled steel tubes, additional standards such as GB5310 - 2008 and GB/T 20409 - 2006 are relevant, as well as ASME SA - 213M - 2015. The size range for these tubes typically extends from an outer diameter (O.D.) of Φ22mm to Φ82.6mm and a wall thickness (WT.) of 4.0mm to 16.0mm, although the processable sizes are determined by meeting specific requirements.

These tubes are predominantly utilized in the power generation and energy industry, specifically in boiler systems for subcritical and supercritical pressure operations. They are employed in furnace walls and other heat - exchange components, enhancing safety for both natural and assisted circulation. Their use decreases the weight of downcomers, headers, drums, connecting pipes, and pump power, while also reducing the framework weight, contributing to the overall system efficiency.

The advantages of internally rifled boiler tubes are substantial, particularly in high - pressure environments. They offer higher heat transfer at higher steam quality levels, which is essential for sustaining efficiency as steam conditions become more exacting. They also perform better at lower mass flux, decreasing the mean metal temperature and optimizing heat transfer through their rifle geometry. This design can enhance thermal efficiency by up to 30% compared to bare tubes, with optimized versions providing an additional 20% improvement over ordinary multi - lead rifled tubes.

An unexpected aspect is their role in modern power plants, where improved fuel efficiency and reduced CO2 emissions are prioritized. The increased internal surface area, resulting from multiple butterfly ribs in some designs, can enhance boiler energy output efficiency, addressing the requirements for higher steam pressure and temperature.

Despite their benefits, internally rifled boiler tubes are generally costlier than plain tubes, reflecting the complexity of their manufacturing process and the materials used. Current research is centered on further enhancing their efficiency, driven by the potential to improve power plant performance. This research includes projects like Siemens' SLMF (Siemens Low Mass Flux), aimed at optimizing their use in modern boiler systems.

Historically, these tubes are sometimes called Serve tubes, named after their French inventor. However, Serve's original design was for fire - tube boilers and had lobes or fins instead of rifles. Modern internally rifled tubes are distinct, designed for water - tube boilers used in power stations. Variants include multi - lead rifled tubes (Type A and Type B, with a 30 - degree helix angle) and optimized multi - lead rifled tubes, which can have a helix angle of up to 40+ degrees, offering enhanced performance.

Compared to plain tubes, internally rifled boiler tubes offer a larger safety margin for circulation and economic benefits, such as reduced material and operational costs in high - pressure applications. Their ability to suppress film boiling and maintain nucleate boiling is a key factor in their adoption, especially in conventional boilers where safety and efficiency are of utmost importance.

In some cases it may be possible to work outside the potential manufacturing range. Please do not hesitate to contact us.

We manufacture with low carbon steel tube and low alloy tube.

We can provide the outer diameter range from 28.6 mm to 76.2 mm.

Lead angle: 30 degrees relative to pipe axis.

Steel pipes used in furnace power plants and other facilities with high temperature and pressure that are used to prevent film boiling.

Inside the water wall tubes of boilers in subcritical steam power plants, water boils into steam vapour. Inside high temperature/high pressure boilers, a special type of boiling occurs called film boiling. A layer of vapour forms at the interface between the liquid and the water wall of the tube. When film boiling occurs, the heat transfer efficiency is reduced due to the layer of steam. Since heat cannot be effectively transferred from the tube to the water, the rise in tube temperature can cause boiling explosions due to overheating, resulting in equipment damage.

A rifled tube contains multiple butterfly fins on the inner surface of the steel tube, which swirl the water inside and create turbulence that suppresses film boiling. Multiple ribs greatly increase the internal surface area of the tube compared to unribbed steel tubes, resulting in increased boiler energy output efficiency. Internally finned tubes help to reduce mass flow and ensure adequate cooling of the internal surfaces of the tubes.

In recent years, power plant boilers have been required to have improved fuel efficiency and improved (reduced) CO2 emissions. These improvements require steam vapour to be heated and pressurised, hence the need for finned tubes.

Multi-rifled seamless steel tube are produced to meet specific end use requirements, specifications, tolerances and chemistries.

| Grade | O.D.(mm) | W.T.(mm) | Number of rib |

|---|---|---|---|

| 20G 15CrMoG SA-210A1 SA-210C SA-213 T2 SA-213 T12 |

22-83 | 4.5-13 | 4-14 |

| Material (Grade) | C | Mn | Si | Cr | Mo | S | P |

|---|---|---|---|---|---|---|---|

| 20G | 0.17~0.23 | 0.35~0.65 | 0.17~0.37 | --- | --- | ≤0.020 | ≤0.025 |

| 20MnG | 0.17~0.23 | 0.70~1.00 | 0.17~0.37 | --- | --- | ≤0.020 | ≤0.025 |

| 25MnG | 0.22~0.29 | 0.70~1.00 | 0.17~0.37 | --- | --- | ≤0.020 | ≤0.025 |

| 12CrMoG | 0.08~0.15 | 0.40~0.70 | 0.17~0.37 | 0.40~0.70 | 0.40~0.55 | ≤0.020 | ≤0.025 |

| 15CrMoG | 0.12~0.18 | 0.40~0.70 | 0.17~0.37 | 0.80~1.10 | 0.40~0.55 | ≤0.020 | ≤0.025 |

| SA-210A1 | ≤0.27 | ≤0.93 | ≥0.10 | --- | --- | ≤0.035 | ≤0.035 |

| SA-210C | ≤0.35 | 0.29~1.06 | ≥0.10 | --- | --- | ≤0.035 | ≤0.035 |

| SA-213T2 | 0.10~0.20 | 0.30~0.61 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 | ≤0.025 | ≤0.025 |

| SA-213T12 | 0.05~0.15 | 0.30~0.61 | ≤0.50 | 0.80~1.25 | 0.44~0.65 | ≤0.025 | ≤0.025 |

| Material (Grade) | Tensile strength (MPa) | Yield strength (MPa) | Elongation(%) | Hardness |

|---|---|---|---|---|

| 20G | 410~550 | 245 | ≥24 | --- |

| 20MnG | ≥415 | ≥240 | ≥22 | --- |

| 25MnG | ≥485 | ≥275 | ≥20 | --- |

| 12CrMoG | 410~560 | ≥205 | ≥21 | --- |

| 15CrMoG | 440~640 | ≥235 | ≥21 | --- |

| SA-210C | ≥415 | ≥255 | ≥30 | ≤143HBW |

| SA-210A1 | ≥485 | ≥275 | ≥30 | ≤179HBW |

| SA-213T2 | ≥415 | ≥205 | ≥30 | ≤163HBW |

| SA-213T12 | ≥415 | ≥220 | ≥30 | ≤163HBW |

| Material (Grade) | Heat treatment |

|---|---|

| 20G | Normalizing at 900℃~930℃, the holding time is 1min/mm according to the wall thickness, but should not be less than 12min. |

| 20MnG | Normalizing at 900℃~930℃, the holding time is 1min/mm according to the wall thickness, but should not be less than 12min. |

| 25MnG | Normalizing at 900℃~930℃, the holding time is 1min/mm according to the wall thickness, but should not be less than 12min. |

| 12CrMoG | 900°C~930°C normalizing; 670°C~720°C tempering, holding time: Periodic furnace is more than 2h, continuous furnace is more than 1h. |

| 15CrMoG | Normalizing at 930°C~960°C; tempering at 680°C~720°C, holding time: periodic furnace greater than 2h, continuous furnace greater than 1h. |

Seamless steel pipe is regularly used in the transportation of fluids such as water, natural gas, waste and air. It is also regularly required in many high-pressure, high-corrosive environments such as in the oil & gas, power generation and pharmaceutical industries. Some common uses of seamless pipes include:

Chemical composition inspection, mechanical properties test(tensile strength,yield strength, elongation, flaring, flattening, bending, hardness, impact test), surface and dimension test,no-destructive test, hydrostatic test.

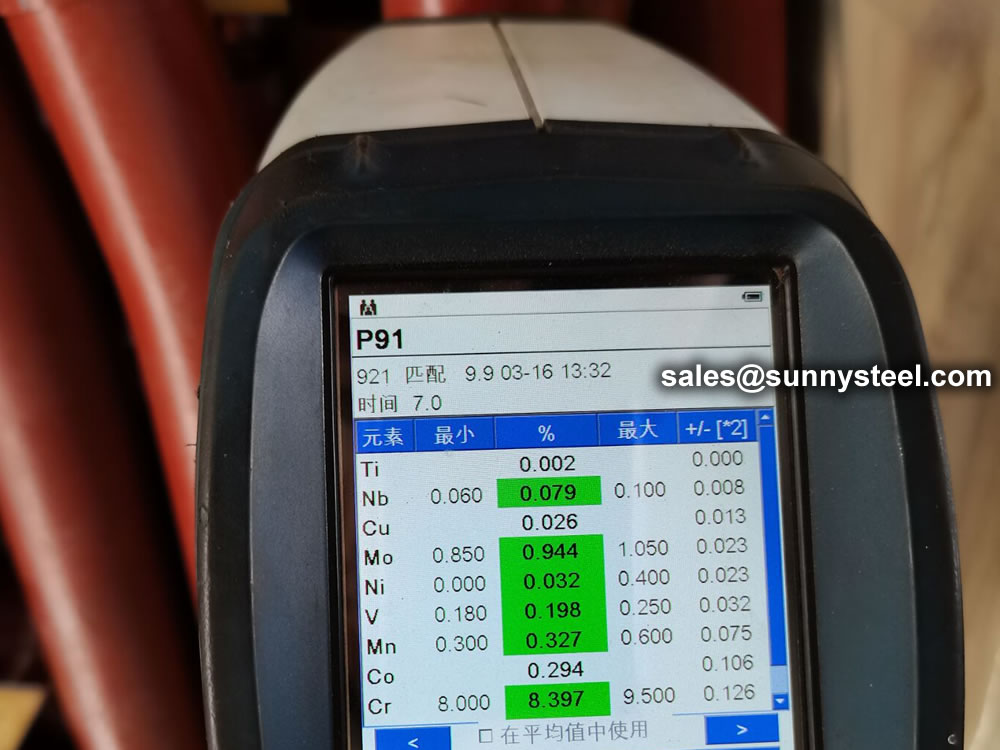

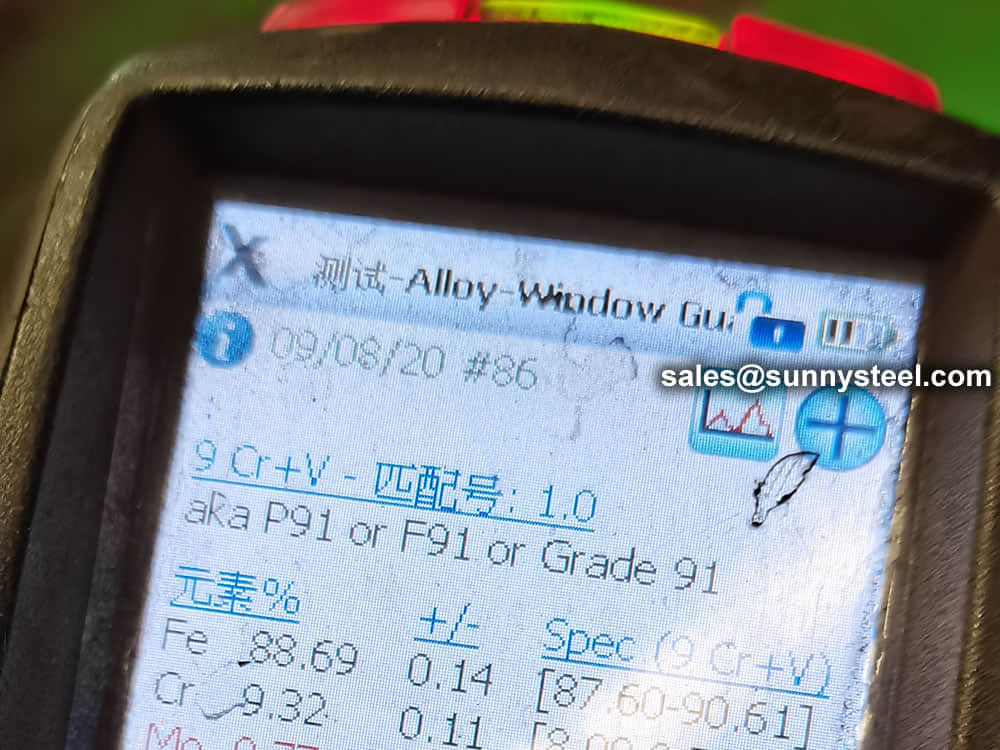

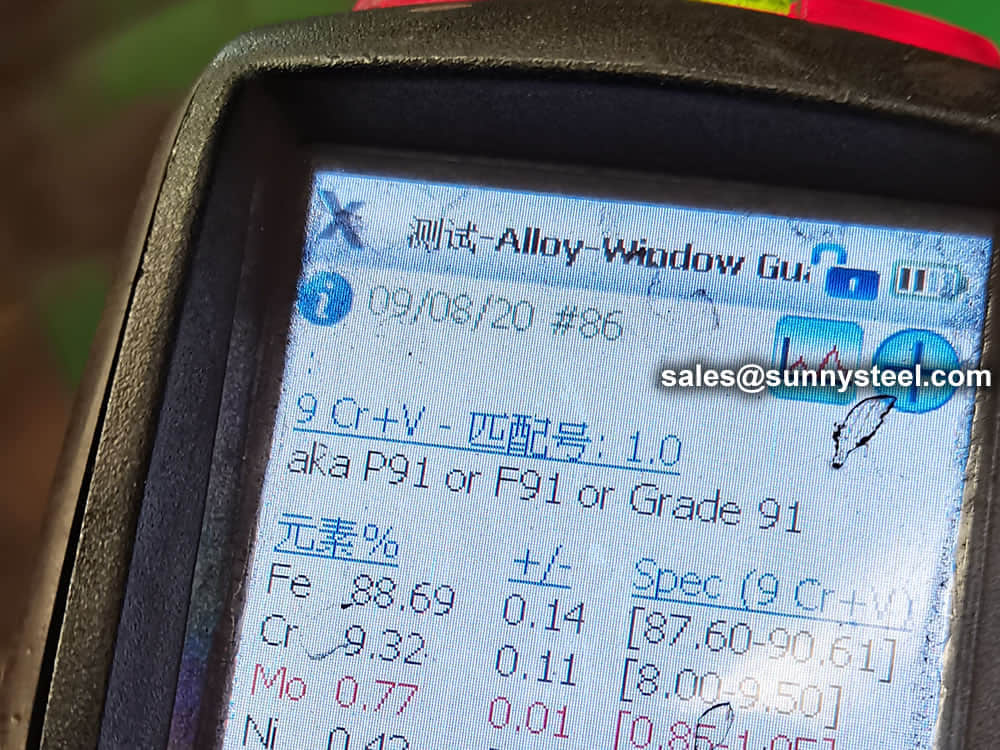

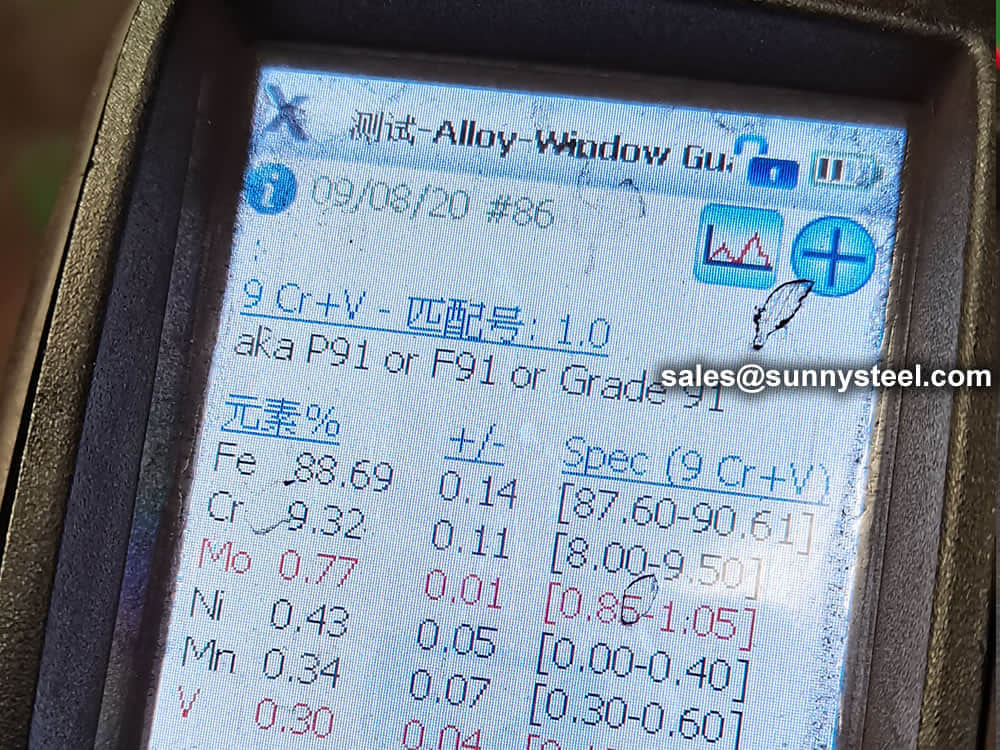

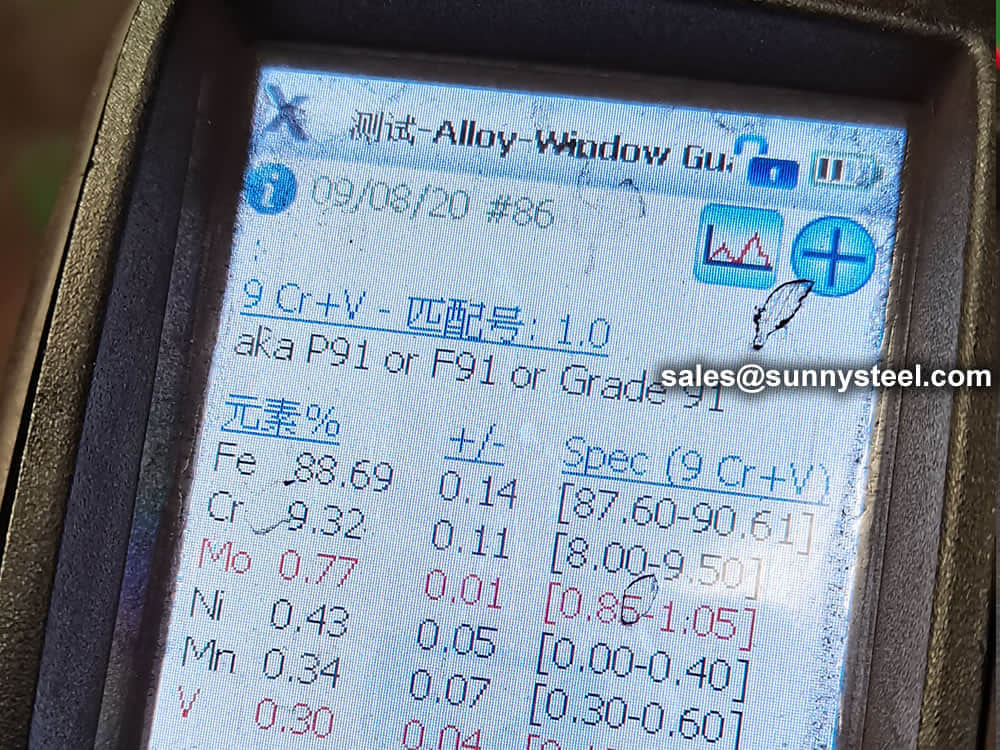

identification of the chemical composition of the metal used to manufacture the fitting. Uses PMI sensors, including X-ray fluorescence or optical emission spectrometry.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

The general cold strip mills, volume should go through continuous annealing (CAPL unit) to eliminate cold hardening and rolling stress, or batch annealing reach the mechanical properties of the corresponding standard specifies. Cold rolled steel surface quality, appearance, dimensional accuracy better than hot-rolled plate, and right-rolled thin product thickness is about 0.18mm, so the majority of users favor.

Cold rolled steel coil substrate products deep processing of high value-added products. Such as electro-galvanized, hot dip galvanized, electro-galvanized fingerprint resistant, painted steel roll damping composite steel, PVC laminating steel plates, etc., so that the excellent quality of these products has a beautiful, high resistance to corrosion, has been widely used.

Cold rolled steel coil finishing after annealing, cut the head, tail, trimming, flattening, smooth, heavy volume, or longitudinal clipboard. Cold-rolled products are widely used in automobile manufacturing, household electrical appliances, instruments, switches, buildings, office furniture and other industries. Steel plate strapping package weight of 3 to 5 tons. Flat sub-volume typically 3 to 10 tons / volume. Coil diameter 6m.

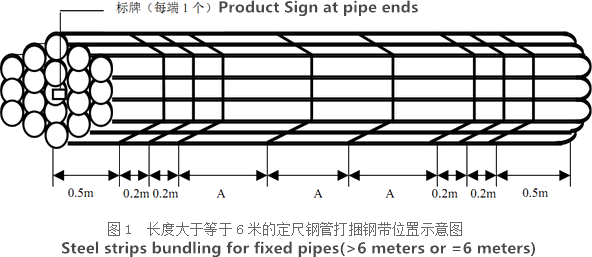

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.

Commonly used alloying elements and their effects are listed in the table given below.

| Alloying Elements | Effect on the Properties |

|---|---|

| Chromium | Increases Resistance to corrosion and oxidation. Increases hardenability and wear resistance. Increases high temperature strength. |

| Nickel | Increases hardenability. Improves toughness. Increases impact strength at low temperatures. |

| Molybdenum | Increases hardenability, high temperature hardness, and wear resistance. Enhances the effects of other alloying elements. Eliminate temper brittleness in steels. Increases high temperature strength. |

| Manganese | Increases hardenability. Combines with sulfur to reduce its adverse effects. |

| Vanadium | Increases hardenability, high temperature hardness, and wear resistance. Improves fatigue resistance. |

| Titanium | Strongest carbide former. Added to stainless steel to prevent precipitation of chromium carbide. |

| Silicon | Removes oxygen in steel making. Improves toughness. Increases hardness ability |

| Boron | Increases hardenability. Produces fine grain size. |

| Aluminum | Forms nitride in nitriding steels. Produces fine grain size in casting. Removes oxygen in steel melting. |

| Cobalt | Increases heat and wear resistance. |

| Tungsten | Increases hardness at elevated temperatures. Refines grain size. |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.