Rubber expansion joint

is a flexible connector to absorb noise, shock, vibration, physical and thermal energy.

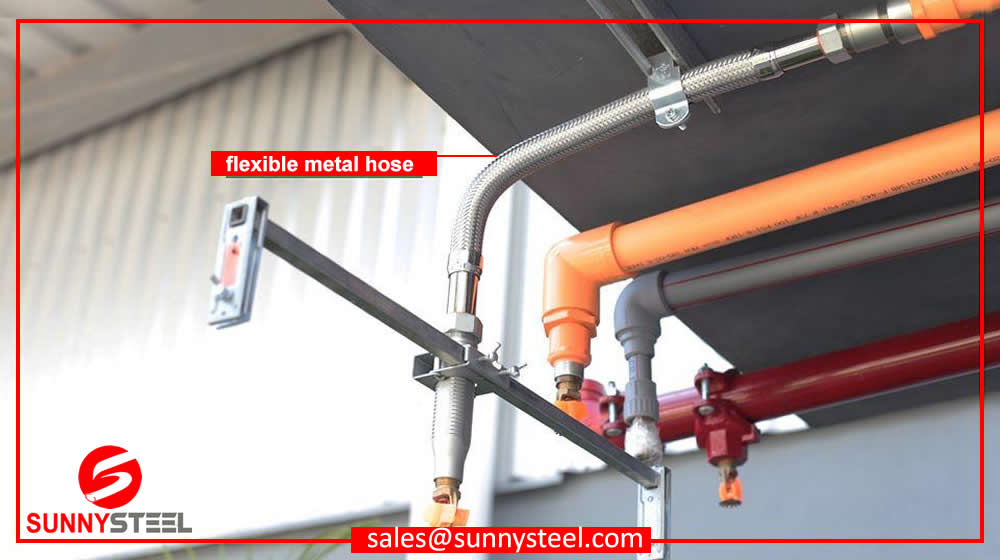

Stainless steel metal hoses are flexible hoses made from stainless steel, typically used for conveying various fluids or gases in industrial applications.

Download PDF

These hoses are constructed from thin-walled stainless steel tubes that are formed, welded, and corrugated to add flexibility and strength.

Stainless steel metal hoses offer advantages such as high temperature resistance, corrosion resistance, and durability. They are commonly used in industries like oil and gas, chemical processing, power generation, and food processing, where there is a need for reliable and flexible hose assemblies.

These hoses can be single braided or double braided with stainless steel wire braidings for added reinforcement. The braiding provides additional strength and protection against external damage.

Stainless steel metal hoses are available in various sizes, lengths, and pressure ratings to suit different applications. They are often used for applications that require flexible connections, vibration absorption, or where there is movement or misalignment between equipment.

When selecting a stainless steel metal hose, factors such as the type of fluid or gas being conveyed, operating temperature and pressure, and compatibility with the surrounding environment should be considered.

It's important to consult with a reputable manufacturer or supplier to ensure that the stainless steel metal hose chosen meets the specific requirements of the application.

The inner tube of metal bellows hose is spiral or annular thin-wall stainless steel bellows, the outer braid mesh of bellow pipe(corrugated pipe) is made of stainless steel wire and steel belt according to certain parameters,the joints or flanges on both ends of the hose are matched to the joint or flange of the customer's pipe.

Flexible metal hoses can withstand high temperatures, making them suitable for use in high-temperature applications. They are commonly used in steam and hot water applications, as well as in high-temperature air and gas applications.

| Nominal diameter DN | Inner |

Outer diameter | Minimum bending | Working pressure | |||

|---|---|---|---|---|---|---|---|

| Bellows | Braid mesh | Static | Dynamic | Single braid mesh | Double braid mesh | ||

| 8 | 8.8 | 13.2 | 14.4 | 50 | 110 | 15 | 20 |

| 10 | 11.7 | 16.5 | 17.7 | 65 | 145 | 185 | 20 |

| 15 | 13.5 | 19.5 | 21.1 | 80 | 180 | 18 | 20 |

| 20 | 20.0 | 27 | 28.6 | 120 | 270 | 10 | 15 |

| 25 | 27.0 | 34.5 | 36.1 | 160 | 360 | 6.3 | 10 |

| 32 | 32.0 | 40 | 41.6 | 175 | 400 | 4.0 | 6.3 |

| 40 | 39.6 | 52 | 53.6 | 225 | 510 | 4.0 | 6.3 |

| 50 | 49.7 | 62 | 63.6 | 280 | 640 | 3.0 | 5.0 |

| 65 | 61.2 | 80.2 | 81.8 | 410 | 915 | 3.0 | 5.0 |

| 80 | 79.0 | 96.3 | 97.9 | 486 | 1030 | 3.0 | 5.0 |

| 100 | 101.2 | 119.6 | 121.2 | 610 | 1340 | 2.5 | 4.0 |

| 125 | 124.1 | 145.3 | 146.9 | 700 | 1540 | 2.5 | 4.0 |

| 150 | 149.4 | 180.8 | 182.4 | 810 | 1780 | 2.5 | 4.0 |

SUS 304 Austenite stainless steel is usually referred to as the Japanese name for SS304 or AISI 304 stainless steel.304 stainless steel is a common material of stainless steel, the density of 7.93 g/cm3 and resistance to high temperature 800 ° C.It has good processing performance and high toughness.They are widely used in medical industry and furniture decoration industry and food industry.

A SS304 flexible metal hose is a type of flexible conduit made from stainless steel (specifically SS304 grade) that is used for various industrial applications.

Flexible metal hose made with ss304 has good comprehensive performance of corrosion resistance and formability.Stainless steel 304 flexible metal hose is durable in use, good and inexpensive, will bring the best result of use and good economic benefits to you.

ss321 is a stabilized stainless steel which offers as its main advantage an excellent resistance to intergranular corrosion following exposure to temperatures in the chromium carbide precipitation range from 800 to 1500° F (427 to 816° C).

ss321 also advantageous for high temperature service because of its good mechanical properties. sss321 offers higher creep and stress rupture properties than ss304.Therefore,if your tube needs to work under high temperature conditions, please select the flexible metal hose made by ss321.

Type 316L stainless steel is an extra-low carbon version of the 316 steel alloy. SS316L has good corrosion resistance and is resistant to marine and aggressive industrial atmospheres.The lower carbon content in 316L minimizes deleterious

In order to understand flexible metal hose assemblies and how they serve various applications it’s best to review their anatomy. In its simplest form, a metal hose is made of four basic components:

Separately, these parts are really quite simple. However, they can be customized to form a variety of configurations, enabling flexible metal hoses to be an optimal solution in a number of industries. Let’s examine each of these components individually and discuss how they all work together to create value.

The corrugated tubing is the core component of a flexible metal hose. Not only does it comprise the bulk of an assembly, but it also plays a part in key value-added attributes of the assembly, such as corrosion resistance, pressure rating, and flexibility.

Flexible metal hose also called corrugated metal hose is especially designed to achieve several objectives in pipe work design. With reliable, quick and easy connection with time-saving, pressure and temperature-resistant,absorbing vibrations and expansion etc.

Stainless steel corrugated hose is a general purpose industrial hose and is available in different grades of stainless steel including 304, 316L, 321,etc.There are many different kinds of metal hose fittings,such as gas hose fitting,quick camlock,flange,NPT fittings,BSP fittings,etc.The flexible metal hose with fittings is more conducive to function in the piping system.

A high-coverage braid package can help add to a hose assembly’s cycle life.

The applications that we support range from metal hose requirements for furnace cooling applications, oxygen services, HVAC offsets, hot asphalt jumper hoses, flanged assemblies for flex connectors, chemical processing, petroleum based applications, natural gas, vibration absorption hoses, earthquake hoses and much more. We test our hose assemblies with helium under water, and hydrostatic testing to customer requirements.

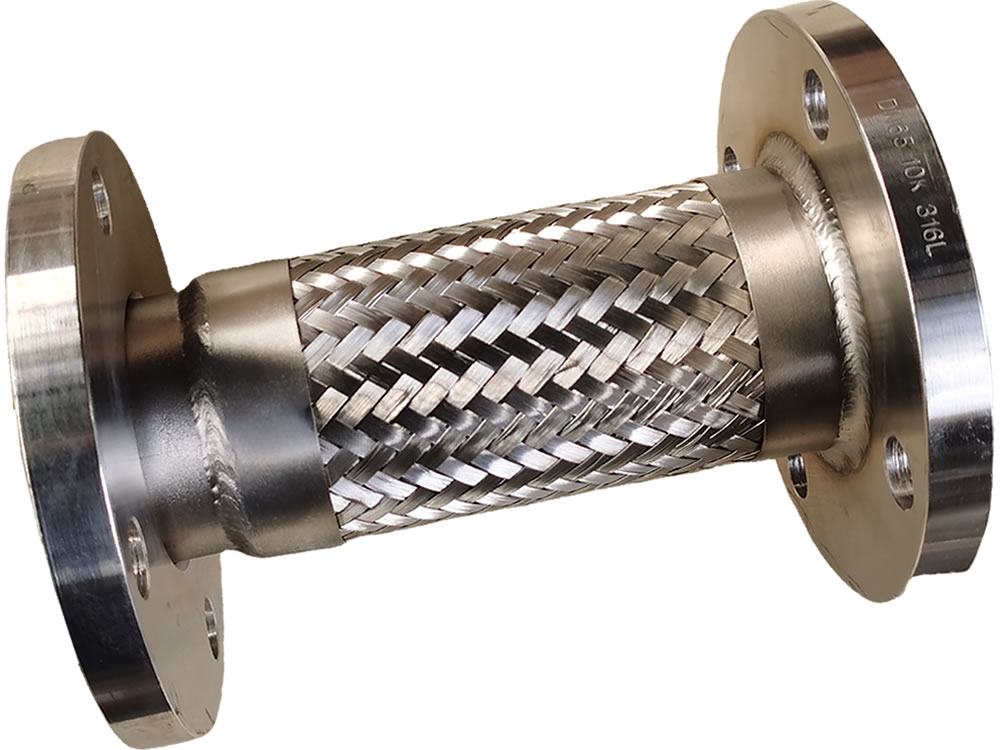

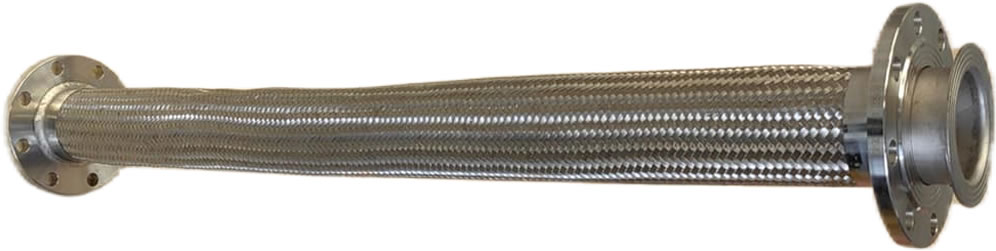

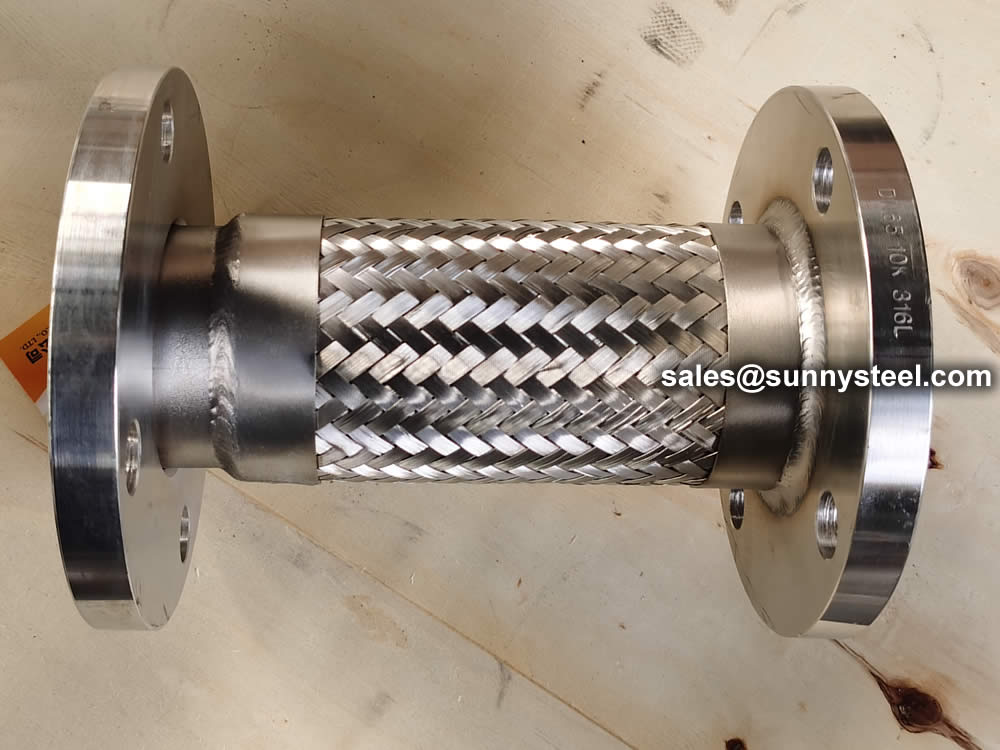

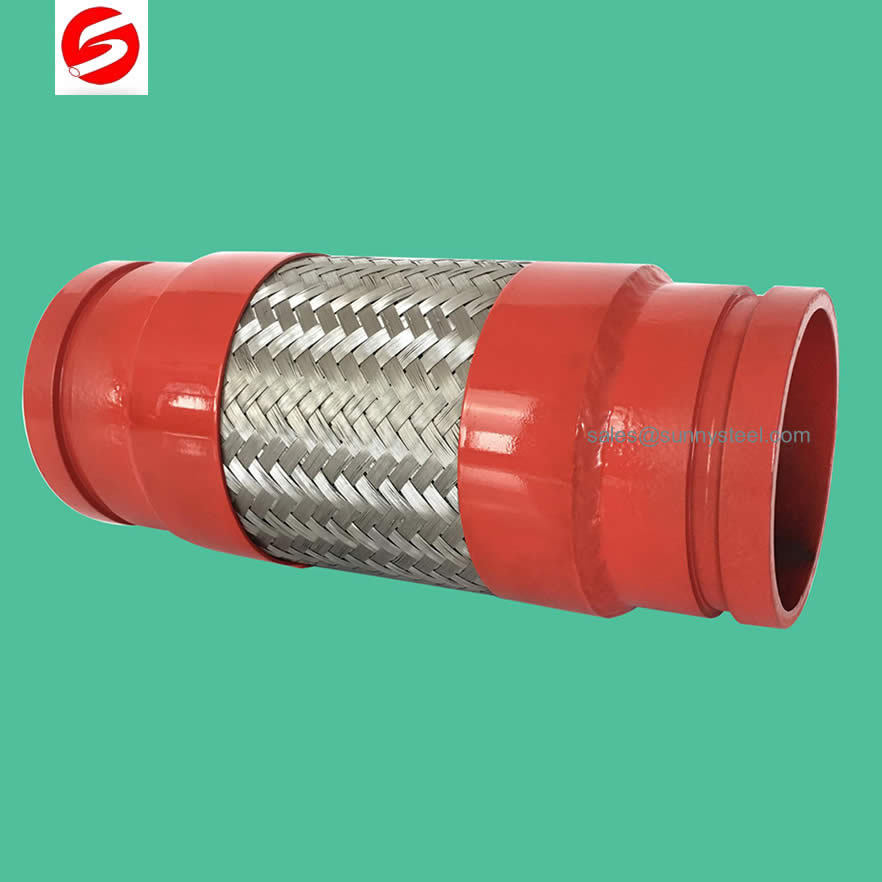

Flange connection type, produced according to customer requirements

High Quality 304 316 Corrugated Stainless Steel Flexible Metal Hose with Flange

Flange connection type, produced according to customer requirements

It is made of flexible bellows tube, nets and joint.

Flange connection metal hose’s application range covers aviation, aerospace, petroleum, chemical engineering, metallurgy, electric power, papermaking, wood, spinning, construction, medicine, food, tobacco, transportation industries, as well as in wiring protection of railway, engine, air-condition, all kinds of machinery, automatic control equipment, electricity generation, power transmission and distribution system, communication system, ship, building, workshop and exposed part in outside.

A stainless steel metal hose is a flexible, corrugated pipe made of high-quality stainless steel that offers exceptional strength, durability, and resistance to extreme temperatures and corrosive environments. The unique design of these hoses enables them to withstand high pressure and handle various fluids, gases, and materials with ease. Stainless steel metal hoses find extensive use in industries such as aerospace, petrochemical, automotive, pharmaceutical, and more.

Stainless steel metal hoses come in various types to meet different industrial requirements. The main types include:

These hoses feature a series of corrugations that provide excellent flexibility and facilitate easy bending. They are ideal for absorbing vibrations and accommodating movement in piping systems.

Braided hoses consist of an outer stainless steel braid that adds additional strength and protection to the hose, making it suitable for high-pressure applications.

Unbraided hoses are simple corrugated hoses without an outer braid, making them lighter and more flexible. They are commonly used in less demanding applications.

Stainless steel metal hoses offer a myriad of benefits that make them the preferred choice in various industries:

- Corrosion Resistance: Stainless steel's natural resistance to corrosion ensures the longevity and reliability of the hose, even in harsh environments.

- High Temperature Resistance: These hoses can handle extreme temperatures, making them suitable for applications in both hot and cold environments.

- Flexibility and Durability: Stainless steel metal hoses are highly flexible, allowing for easy installation and routing in complex systems without compromising strength.

- Pressure Resistance: The robust construction of stainless steel metal hoses allows them to handle high-pressure fluids and gases without leaking or rupturing.

- Versatility: These hoses can transport a wide range of materials, including chemicals, gases, steam, and abrasive materials.

- Low Maintenance: Stainless steel hoses require minimal maintenance, reducing downtime and operational costs.

Stainless steel metal hoses find extensive use in various industries and applications, including:

- Petrochemical Industry: Transporting chemicals and corrosive materials.

- Automotive Industry: Handling exhaust gases and convey fluids.

- Pharmaceutical Industry: Transferring sensitive liquids and gases.

- Aerospace Industry: Handling fuel and hydraulic fluids.

- Food and Beverage Industry: Conveying food-grade liquids and gases.

When selecting a stainless steel metal hose for a specific application, several factors should be taken into account:

- Temperature Range: Ensure that the hose can handle the expected temperature range of the conveyed materials.

- Pressure Rating: Choose a hose with a pressure rating suitable for the application to avoid leaks and failures.

- Hose Diameter and Length: Select the right hose diameter and length to ensure efficient fluid flow and proper installation.

- End Fittings: Consider the type and compatibility of end fittings for seamless connections to the system.

Proper installation and regular maintenance are crucial for maximizing the performance and lifespan of stainless steel metal hoses:

- Follow Manufacturer Guidelines: Install the hose according to the manufacturer's guidelines to avoid stress and strain on the hose.

- Inspect Regularly: Periodically inspect the hose for signs of wear, damage, or leakage, and replace if necessary.

- Avoid Over-Bending: Do not over-bend or kink the hose, as it can weaken the structure and reduce performance.

- Myth: Stainless steel hoses are not flexible.

- Fact: Stainless steel hoses are highly flexible and can be bent to accommodate various configurations.

- Myth: Metal hoses are prone to leaks.

- Fact: Properly installed and maintained stainless steel hoses have excellent leak resistance.

When comparing stainless steel metal hoses with other metal hoses, several factors come into play:

- Corrosion Resistance: Stainless steel outperforms other metals in resisting corrosion.

- Temperature Range: Stainless steel handles a broader temperature range than most other metals.

- Look for reputable manufacturers known for producing high-quality stainless steel metal hoses.

- Check for certifications and approvals from relevant authorities.

Stainless steel metal hoses are versatile, reliable, and indispensable components in various industries. Their exceptional durability, flexibility, and resistance to corrosion and high temperatures make them the preferred choice for a wide range of applications.

Whether it's conveying chemicals, handling high-pressure fluids, or transporting food-grade materials, stainless steel metal hoses prove their worth time and again. By understanding their capabilities, considering key factors in selection, and following proper installation and maintenance practices, industries can harness the full potential of stainless steel metal hoses to optimize their processes and ensure safe and efficient operations.

Q: What is the working temperature range of stainless steel metal hoses?

A: Stainless steel hoses can handle a wide temperature range, typically from -300°F to 1500°F (-184°C to 816°C), depending on the specific grade and construction.

Q: Are stainless steel metal hoses suitable for high-pressure applications?

A: Yes, stainless steel metal hoses are designed to withstand high-pressure fluids and gases, making them ideal for various industrial applications.

Q: Can stainless steel metal hoses resist corrosion?

A: Absolutely! Stainless steel's inherent corrosion resistance ensures that these hoses remain durable and reliable even in highly corrosive environments.

Q: Are stainless steel metal hoses suitable for food-grade applications?

A: Yes, stainless steel metal hoses are commonly used in the food and beverage industry to transport food-grade liquids and gases safely and hygienically.

Q: Are stainless steel metal hoses flexible?

A: Yes, stainless steel metal hoses are highly flexible, allowing for easy installation and routing in complex systems without compromising their structural integrity.

Q: Can stainless steel metal hoses be used for transferring chemicals and hazardous materials?

A: Yes, stainless steel metal hoses are ideal for transporting chemicals and other hazardous materials due to their excellent corrosion resistance and durability.

Q: How do I select the right size of stainless steel metal hose for my application?

A: To select the right size, consider factors like the expected flow rate, pressure, and temperature of the conveyed material, and consult with hose experts or manufacturers if needed.

Q: Are stainless steel metal hoses suitable for high-temperature applications?

A: Yes, stainless steel metal hoses are specifically designed to handle high-temperature fluids and gases, making them suitable for a wide range of industrial processes.

Q: Can stainless steel metal hoses be used for cryogenic applications?

A: Yes, stainless steel hoses can handle cryogenic temperatures and are used in applications that involve low-temperature fluids or gases.

Q: How often should stainless steel metal hoses be inspected and replaced?

A: Regular inspections are essential to identify signs of wear, damage, or leakage. Depending on the application and conditions, hoses may need replacement every few years or as recommended by the manufacturer.

Widely used in aviation, aerospace, petroleum, chemical, metallurgy, power, paper, wood, textile, construction, pharmaceutical, food, tobacco, transportation and other industries.

The applications that we support range from metal hose requirements for furnace cooling applications, oxygen services, HVAC offsets, hot asphalt jumper hoses, flanged assemblies for flex connectors, chemical processing, petroleum based applications, natural gas, vibration absorption hoses, earthquake hoses and much more.

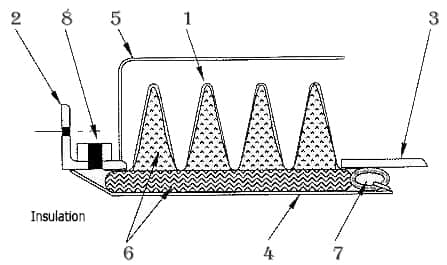

Accessories are added to an expansion joint installation to meet specific customer, application or code requirements. Some are used to control movement, others to protect the bellows in the event of pressure thrust, and still others to defend against corrosion caused by media inside or from the environment outside the bellows.

Divide piping into two separate segments insuring proper movement of each bellows in double type expansion joint.

Used in conjunction with internal sleeve to:

Internal liners can be used to either protect the metallic bellows from erosion or reduce turbulence across the bellows. They must be used when purge connectors are included in the design. In order to provide enough clearance in the liner design, appropriate lateral and angular movements must be specified by the designer. When designing an expansion joint with combination ends, flow direction must be specified as well.

External covers should be used to protect the internal bellows from being damaged. They also serve a purpose as insulation of the bellows. Covers can either be designed as removable or permanent accessories.

In systems that have a media with significant particulate content (i.e. flash or catalyst), a barrier of ceramic fiber can be utilized to prevent corrosion and restricted bellows flexibility resulting from the accumulation of the particulate. Purge connectors may also be utilized to perform this same function. Internal liners must also be included in the design if the expansion joint includes purge connectors or particulate barriers.

Limit rods may be used in an expansion joint design to limit the axial compression or expansion. They allow the expansion joint to move over a range according to where the nut stops are placed along the rods. Limit rods are used to prevent bellows over-extension while restraining the full pressure thrust of the system.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.