Basalt lined pipes

for Japanese steel plants

Cast basalt composite elbow is a type of piping component used in industrial applications where highly abrasive or corrosive materials are being transported.

Download PDF

A cast basalt composite elbow is a type of pipe fitting used in high-abrasion applications. It is made by casting basalt rock into the shape of an elbow and then binding it with a composite material. This process produces a high-strength, wear-resistant material that is ideal for handling abrasive materials like sand, gravel, and mining slurries.

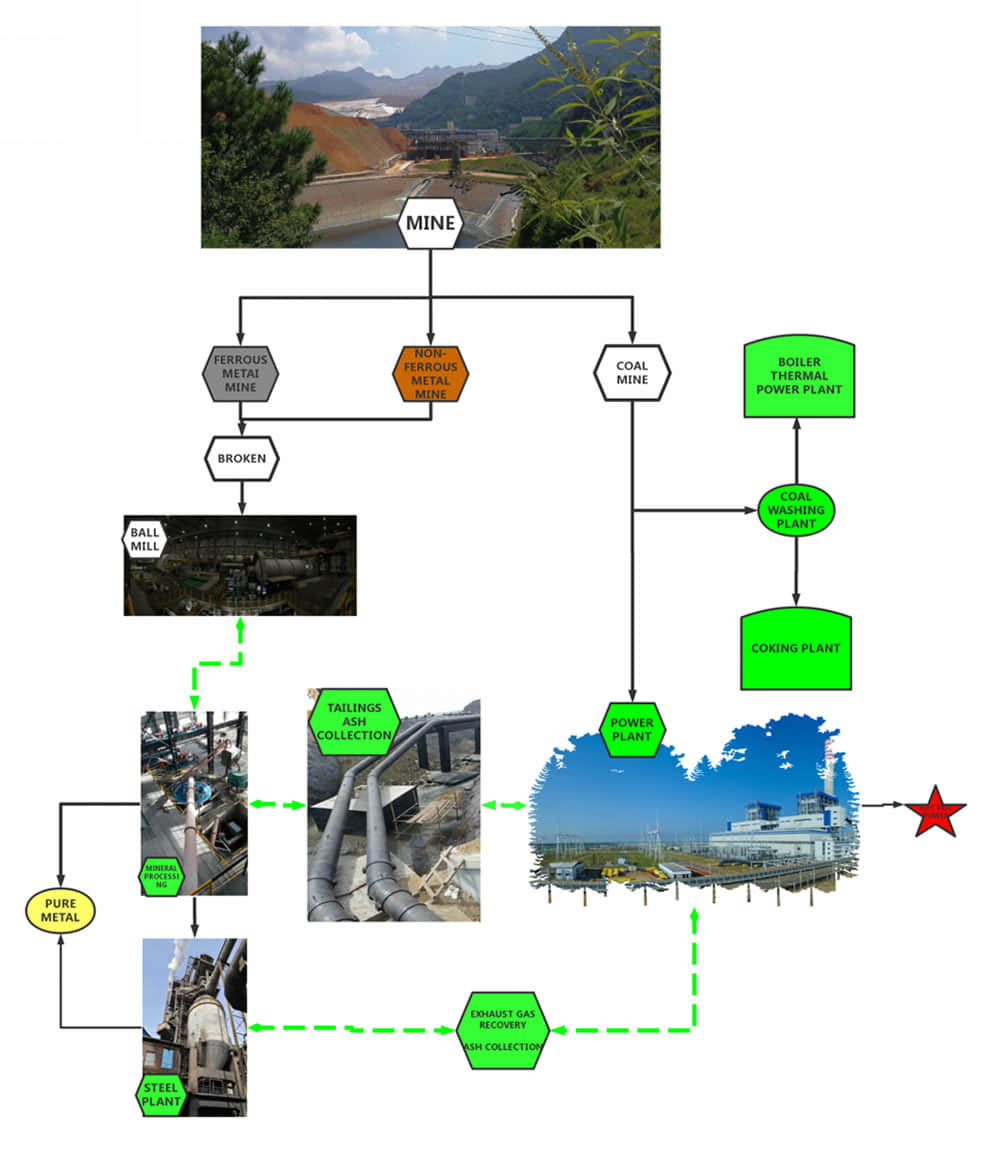

Cast basalt composite elbows are commonly used in mining and mineral processing, where the abrasiveness of the materials being handled can cause regular pipe fittings to wear out quickly. They are also used in power generation, chemical processing, and other heavy industries where abrasion resistance is a concern.

The benefits of cast basalt composite elbows include their durability, resistance to wear and erosion, resistance to chemical attack, and their ability to handle high temperatures. They can also be customized to fit specific pipe sizes and angles, making them a versatile option for many different applications.

Cast basalt composite elbow is made by molding layers of cast basalt around a steel pipe elbow, creating a composite structure that combines the toughness and wear resistance of cast basalt with the strength and flexibility of steel.

The cast basalt layer of the composite elbow provides excellent abrasion and corrosion resistance, reducing the need for frequent maintenance and replacement. The steel core provides support and structural integrity, enabling the elbow to withstand high pressure and mechanical stress. The combination of these materials results in a piping component that is both durable and versatile, making it an ideal choice for a range of industrial applications.

Some of the benefits of cast basalt composite elbows include improved process efficiency, reduced downtime and maintenance costs, and increased safety and reliability. They can be used in industries such as mining, power generation, chemical processing, and more, and are often employed in areas of high wear and tear, such as bends and transitions in pipelines.

In summary, cast basalt composite elbow is a piping component designed to provide excellent resistance to abrasion and corrosion while maintaining structural integrity under high stress conditions. Its unique construction enables it to withstand the toughest industrial environments and provide reliable, long-lasting performance.

| Cast Basalt Pipe DN (mm) |

Standard Steel Pipe OD (mm) |

Cast Basalt Thickness (mm) |

Length (mm) |

|---|---|---|---|

| 80 | 159 | 25 | 4000 |

| 100 | 168 |

17.5 20 |

4000 6000 8000 |

| 125 | 195 | ||

| 150 | 219 | ||

| 175 | 245 |

6000 8000 10000 12000 |

|

| 200 | 273 | ||

| 225 | 300 | ||

| 250 | 325 | ||

| 275 | 345 | ||

| 300 | 377 | ||

| 350 | 426 | ||

| 400 | 478 |

20 25 |

|

| 450 | 529 | ||

| 500 | 600 | 25 | |

| 550 | 650 | ||

| 600 | 720 | 30 | 6000 |

| 650 | 770 | ||

| 700 | 820 | ||

| 750 | 870 | ||

| 800 | 920 |

Other specifications of cast steel pipe lined with basalt can be manufactured according to customer technical requirements. Suitable for large-diameter basalt lining steel pipes with a nominal diameter greater than 800mm. Generally, according to the running status of the pipeline, different cement is used to fix the basalt brick inside the finished steel pipe to complete the basalt lining steel pipe. Its advantages are good wear resistance, wide range of use, basically not limited by the size of the pipeline and low cost of pipeline installation.

Comparison of Ceramic lines with few other materials under standard conditions :

| Material | Thickness(mm) | Approx life ( Months ) |

|---|---|---|

| Mild Steel | 10 | 3-5 |

| Cast Iron | 20 | 6-8 |

| Ni-Hard | 20 | 12-14 |

| Cast Basalt | 30 | 20-25 |

| Ceramic | 10 | 35-40 |

Hard & Compact Smooth & Inner Withstands High-Abrasion & Corrosion In any of the process industries especially Sled and Cement corrosion and abrasion lead to significant downtime of the plant. Further, the useful life or the equipment itself may get impaired because of the high abrasive nature of the materials being used. Thus, ‘wear mechanism’ results in hut down, replacement, etc., which is costly, resulting in loss to tilt: tunic of millions of dollars.

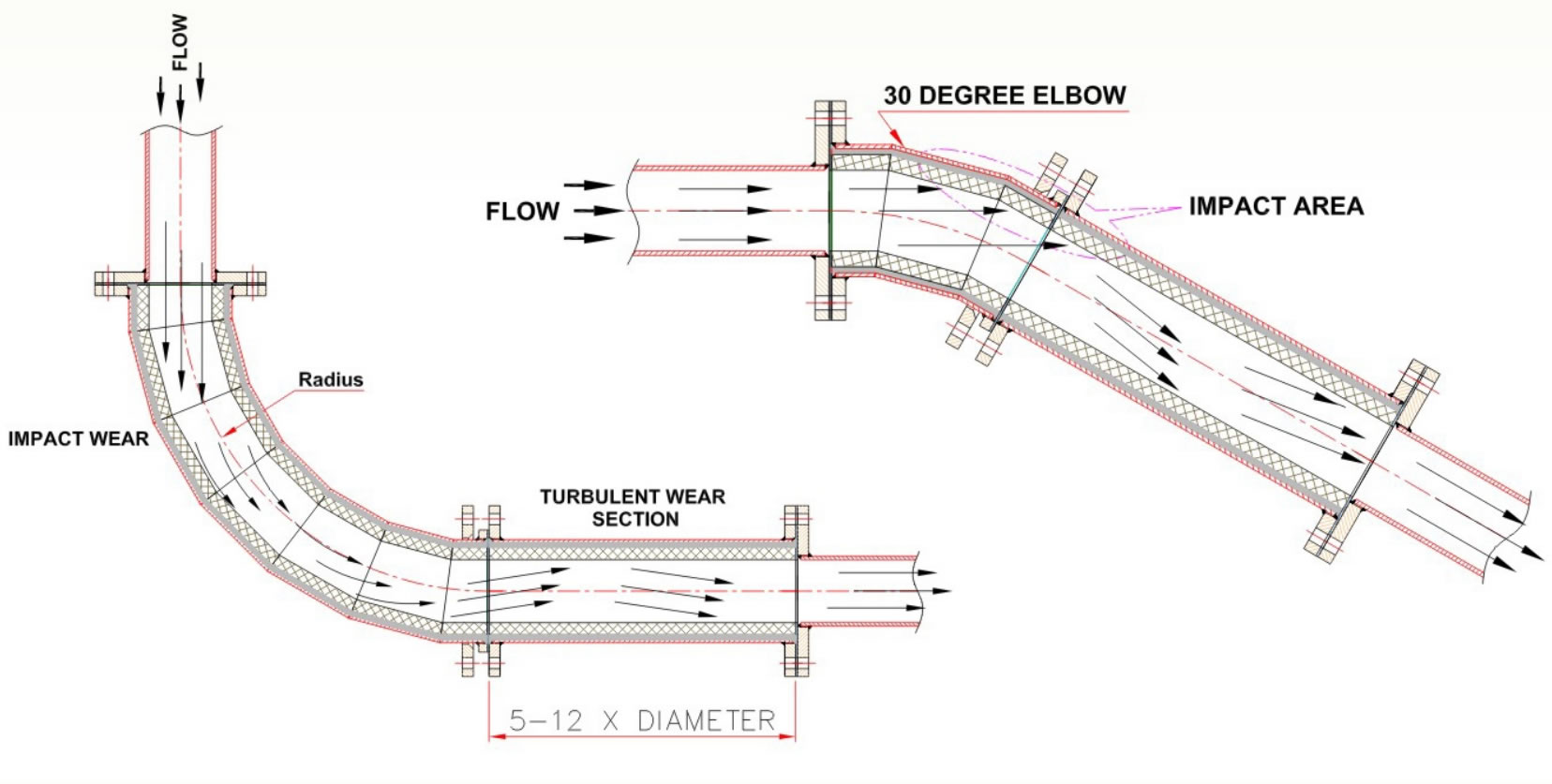

The bend radius should be minimum 3 times of the nominal bore. At discharge end of each bend, cast basalt lined straight pipe of length 5 to 12 times the nominal bore must be used.

Cast basalt pipe can be divided into straight pipe, elbow, three-way (four-way) pipe and variable diameter pipe, etc.

Cast basalt lined pipes exhibit exceptional wear resistance due to several key characteristics:

Cast basalt lined pipes are engineered with a well-thought-out structure. The internal arrangement consists of interlaced pyroxene spheres or feather-like crystallites of 0.05-0.1 mm, enhancing the material's hardness and wear resistance.

These pipes have low water absorption, contributing to their resistance against the deteriorating effects of moisture.

Cast basalt pipes possess high compressive strength, enabling them to endure heavy loads and pressures without deformation.

With the exception of hot phosphoric acid, hydrofluoric acid, and dissolved alkali above 30℃, cast basalt exhibits excellent corrosion resistance to a wide range of substances, including inorganic acids, organic acids, alkalis, salts, water, and organic solvents.

The material's Mohs hardness reaches 7-8, indicating a high level of hardness that directly correlates with superior wear resistance. Harder materials generally exhibit better resistance to wear and abrasion.

The combination of silicon and oxygen atoms in the silicate mineral structure is bound by strong forces at the atomic and molecular levels, contributing to the overall strength of the material.

While individual cast basalt lined pipes demonstrate good wear resistance in applications like blast furnace tanks, it's important to note the inherent brittleness of ceramic materials. This brittleness may result in breakage during heavy impacts. Additionally, single-piece pasting construction may exhibit signs of aging over extended periods. However, when properly applied and maintained, cast basalt lined pipes remain a popular choice for wear-resistant applications due to their durability and performance.

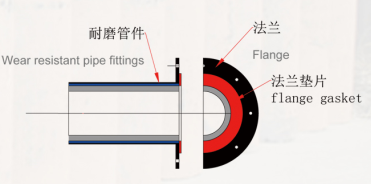

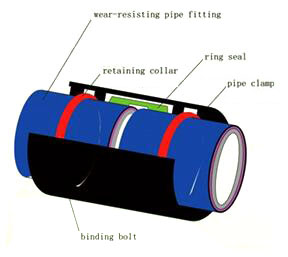

Cast blast lined pipe and fittings can connect with flange, quick assembly joints and welding.

Flange connection is one kind of common pipeline installation connections. By two pieces of flanges, pipeline, valve, equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority selection. Flanges have lots of different sizes. Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

The parameters of the outside steel pipe will be decided according to the working pressure of the system. The connection of the pipes and fitting will be of flange connections, easy—flexible joint connection or by welding.

By two pieces of flanges,pipeline,valve,equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority secection. Flanges have lots of differents sizes.

Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

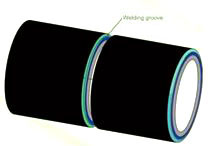

Beveled ends allow for proper alignment and penetration during welding, ensuring a strong and effective joint. This preparation is commonly used in various industries, especially in piping systems where welded connections are prevalent.

It suits short distance pipeline system without maintenance. It is one kind of common installation connections. It requires installation personnel higher welding ability. It also restricts by welding site, distance, welding positions. Welding connections is inconvenient in later maintenance.

It is one of high efficient and rapid installation connection. I t has the below characteristic: easily install and disassemble, fast installation, temperature adjustable compensation function, saving the necessary expansion in long pipeline. Easy-flexible joint also has angle compensation characteristic. At smaller angle turning points, easy-flexible joint can be instead of bends and adjust angle.

Cast basalt can be used for the lining of pipework, chutes, bunkers, cyclones, and hoppers.

It has become the global standard in areas such as ash slurry pipework, often used at fossil-fuel power stations. It is an all-round cost-effective and adaptable lining material that extends the life of equipment in pipe or tile form where affected by erosion.

Cast basalt is well-proven in a variety of industries as a cost-effective, long-lasting lining material used to extend the operating life of equipment manufactured or lined with lower-wearing materials such as steel, cast iron, rubber, and polyurethane.

Cast basalt lined steel pipe, as both a wear—resistant and corrosion—resistant materials, the transport properties of wear or corrosion of materials, after thirty years of practical verification, cast basalt lined steel pipe can be well done.

Cast basalt is also used in cement plants for making air separators, chain conveyor, silica hoppers, nozzles, coal hoppers, cement hoppers, cyclones, raw mill ducts, chutes, thick slurry lines, mixers, grate cooler housing, coal ventury etc.

Cast basalt is a mineral of exceptionally high abrasion resistance, unlimted resistance to moisture, high compressive strength and resistance to virtually all acids and alkalis and is completely corrosion free.

Cast basalt is produced by melting selected natural basalt broken into sizes of 20-50 mm in shaft furnaces at tempreatures around 1,300C, following by casting at which the metled basalt forms uniforms pherolithic crystals hence producing its typical physical propertics, in particular its exceptional hardness and wear-resitance.

Cast basalt reaches a value of hardness of 8( min ) on the Moh's hardness scale. for comparision : the highest value10is only attained by dimonds. by virtue of these properties,the silicate cast basalt provides outstanding protection against abrasion and scrubbing.

however, it is marked by asertain sensitivity ti impacts.Under Normal services conditions, cast basalt withstands tempratures up to approx.+ 350C or-40C. However Cast basalt sholud not be subjected ti temprature shocks.

Sizes : Cast basalt produces are manufactured as tiles, from pieces and segments. straight pipes are spun-cast, available for nominal bores of 32 to 600 mm with the wall thickness ranging from 20 to 30mm and a standard lenght of 500mm.samller nominal bores of straight pipes, pipe segment for radill of 40 to 3,000mm of vatrious angles, as well as special formpiece linings are pre dominately sand-cast. The standard wall-thickness is 20mm. depending on the respective quantity, steel moulds can also be used, the wall thickness in those cases usually being 30 to 40mm.

Cast basalt lined pipe can be mainly used as abrasive material and ash handling system like chute slip trough, funnel, silos, a variety dust catcher, revolving-flow machine, various scraper transport planes, all the feeder liner. Laying the ground all types of chemical plants, it can be for lining picking tank or storage of corrosive substance of the storage room.

According to customer requirements along with cast basalt production technology and we can offer various specifications and various shape to meet client's need.

Friction Resistance : As more material is passed over Cast Basalt it gets polished up thereby reducing friction further. Cast Basalt improves in service after getting polished. Wetting also improves its performance in practical applications.

Impact Resistance : Direct Impact Resistance at 90 degree is low like all other ceramics, but it can be increased with proper installation by reducing the angle of impact. Cast Basalt is the best wherever sliding abrasion exists. Moreover, external impact strength of composite basalt pipe (enclosed in M.S. Shell) is always more than that of bare Ni-hard Pipe.

Chemical Resistance : Cast Basalt is almost absolutely acid/alkali resistant (except Hydrofluoric Acid) and hence corrosion resistant.

Weight and Sizes : Basalt Tiles are available in regular shape square of 200 x 200 x 30 mm thick, weighing approx. 90 kg/sq m; whereas bends and pipes are lined using Basalt Cylinders of various standard sizes from 50NB upto 500NB.

Temperature : Cast Basalt withstands temperature up to 4500 oC.

Design Aspects

Refining basalt to a finely crystallised glass ceramic, SunnySteel’s cast basalt wear resistant material provides an extremely durable, long-lasting lining for static plants bearing large volumes of abrasive and/or corrosive matter.

Supplied as both a pipe and tile lining solution, cast basalt is ideally suited for wet material handling applications with lower impacts, such as coal chutes, ash sluiceways, ash pipelines at power stations and hydraulic granulated slag or sand conveying. Basalt delivers high resistance to wear corrosion and temperatures up to approximately 400 °C.

Cast basalt pipe is a kind of silicate crystalline material that has been produced and processed. It uses natural rock (basalt, diabase and other basic rocks) or some industrial waste slag as the main raw material. After melting, pouring, crystallization and annealing and other processes. Cast stone has excellent wear resistance and corrosion resistance. Cast stone products mainly include cast stone slabs, cast stone pipes, cast basalt lined pipes, jacketed cast stone pipes, cast stone wear-resistant expansion joints, cast stone wear-resistant valves, cast stone powder and various wear-resistant and resistant cast stone powders as raw materials. Putty slime, etc. Has been widely used in electric power, mining, coal, metallurgy, chemical, construction and other industrial sectors severely worn and corroded parts and equipment.

the cast basalt lined pipe is composed of the inner lined cast stone pipe, the outer steel pipe and the cement mortar filling layer between the two. It integrates the wear resistance and corrosion resistance of the cast stone pipe, the toughness of the steel pipe and the consolidation of the cement mortar. In one. It improves the adaptability of the Product to various complex working conditions. At the same time, the use of cement mortar as a filler can make the inner surface of the steel pipe in an alkaline medium, and the surface of the steel pipe will produce a purification film, which can prevent corrosion. It is resistant to wear, corrosion, and high pressure, and is safe and convenient to transport.

Cast basalt lined pipes are divided into straight pipes, curved pipes, tee (cross) pipes, reducing pipes, etc.

The diameter series of the cast stone composite elbow is the same as that of the cast stone composite straight tube, and its turning radius and center angle are made according to user requirements.

Non-standard specifications of cast basalt lined pipes can be made according to customer’s technical requirements. For large-diameter cast basalt lined pipes with a nominal diameter of more than 800mm, different cements are usually used to paste the cast stone plates on the inner wall of the well-processed steel pipes according to the operating conditions of the pipe fittings to form an integrated cast basalt lined pipe. Its advantages are good wear resistance, wide application range, small size limitation of pipe fittings, and low cost of pipe fittings.

Natural gas is used for melting basalt stone in melting furnace. Natural gas is currently very clean and environmentally friendly fuel. No any pollution. To the customer requirements choose environmental protection material that is a good choice.

The product processed from cast basalt is a new type of silicate crystalline material. Using natural rock (basic database, shale, etc.) or industrial waste as the main raw material components, smelting, casting, heat treatment and other processes are regularly arranged, crystalline, hard, and fine-textured metal industrial materials. Casting basalt has an excellent high abrasion and high resistance. Abrasiveness. Corrosion resistance.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed ultrices elit eget sem luctus interdum. Morbi a sapien ut dolor placerat consequat. Nulla facilisi. Vivamus at lacinia elit. Phasellus at faucibus lacus. Duis in enim pharetra, lobortis neque id, ultricies sapien. Sed finibus, arcu vitae suscipit vehicula, purus lectus vestibulum tortor, vel semper justo erat eu risus. Nulla ac odio ac turpis blandit porttitor vitae vitae metus. Fusce commodo lacinia leo quis dictum.

Friction Resistance – As more material is passed over Cast Basalt it gets polished up thereby reducing friction further. Cast Basalt improves in service after getting polished. Wetting also improves its performance in practical applications.

Impact Resistance – Direct Impact Resistance at 90 degree is low like all other ceramics, but it can be increased with proper installation by reducing the angle of impact. Cast Basalt is the best wherever sliding abrasion exists. Moreover, external impact strength of composite basalt pipe (enclosed in M.S. Shell) is always more than that of bare Ni-hard Pipe.

Chemical Resistance Cast Basalt is almost absolutely acid/alkali resistant (except Hydrofluoric Acid) and hence corrosion resistant.

Weight and Sizes - Basalt Tiles are available in regular shape square of 200 x 200 x 30 mm thick, weighing approx. 90 kg/sq m; whereas bends and pipes are lined using Basalt

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.