Stainless steel hexagon bar, also known as hex bar, is a versatile material known for its strength, corrosion resistance, and excellent machinability.

This hexagonal-shaped bar is widely used in various industries, including manufacturing, construction, and automotive sectors, where precision and durability are crucial. The stainless steel hexagon bar is ideal for creating fasteners, gears, and machine components, thanks to its superior mechanical properties. Available in different grades and sizes, it provides a robust solution for both industrial and decorative applications. Its resistance to rust and oxidation makes it suitable for use in harsh environments.

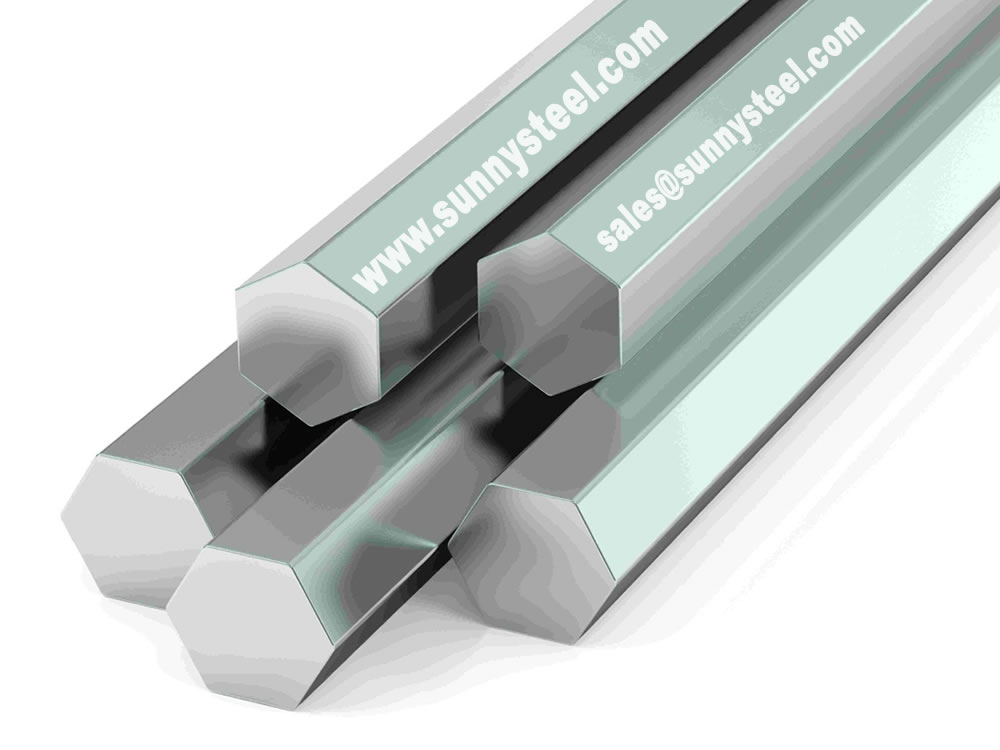

We supply our products in standard lengths or cut to size, and offer rapid response times with full product traceability via a unique barcoding system. We also supply legible, accurate test certification with our materials.

Stainless steel hexagonal bar offers excellent machining characteristics and is the perfect choice for repetitively turned parts, including fasteners such as bolts and nuts. Stainless steel offers unique performance benefits, including excellent corrosion resistance, machinability and workability. It is ideal for use in a broad range of commercial engineering applications, including those in the medical sector, food industry, tooling and mechanical engineering.

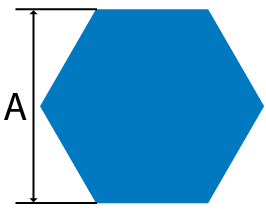

Size Range: Typically available in sizes ranging from 3mm to 100mm across flats (A/F).

Length: Standard lengths are usually 3 meters (10 feet), but custom lengths can be ordered.

Tolerances: Manufactured to tight dimensional tolerances as per standards like ASTM A484 or DIN 1013.

Hot Rolled: Rough surface, suitable for further machining.

Cold Drawn: Smoother surface with tighter tolerances.

Polished: Mirror-like finish for decorative or sanitary applications.

Pickled and Passivated: Improved corrosion resistance with a clean surface.

Fasteners: Bolts, nuts, and screws.

Machinery Parts: Shafts, fittings, and couplings.

Construction: Structural components and decorative elements.

Marine Industry: Equipment and fittings exposed to saltwater.

Automotive: Engine components and custom parts.

Food and Beverage: Equipment requiring hygiene and corrosion resistance.

ASTM A276: Standard specification for stainless steel bars and shapes.

ASTM A484: General requirements for stainless steel products.

EN 10088: European standard for stainless steel bars.

DIN 1013: German standard for hexagonal steel bars.

Stainless steel hexagon bars are solid bars with a hexagonal cross-section, commonly used in applications requiring high strength, corrosion resistance, and durability. They are available in various grades, including 304, 316, and 316L, with 316 stainless steel being particularly popular for its enhanced corrosion resistance due to the addition of molybdenum.

Grade 304/304L provides a balance of strength, corrosion resistance, and weldability, making it suitable for a wide range of applications, including automotive parts, kitchen equipment, and architectural components.

Stainless Steel Hexgon Bar 316/316L With enhanced corrosion resistance, especially against chlorides and other industrial solvents, this grade is commonly used in marine environments, chemical processing equipment, and medical devices.

316 stainless steel hexagon bars are a popular choice for applications requiring excellent corrosion resistance, high strength, and durability.

Stainless Steel 416 is a type of martensitic stainless steel that is renowned for its excellent machinability and corrosion resistance. Stainless Steel 416 Hex Bar is a widely used product made from this steel, and it is employed in a variety of industrial applications. The Stainless Steel 416 Hex Bar is available in different sizes and diameters. Stainless Steel 416 is a type of martensitic stainless steel with excellent machinability and corrosion resistance.

Stainless Steel 416 Hex Bar is a widely used product made from this steel. It is used in various industrial applications for which high strength, good machinability and resistance to corrosion are essential.

We will cut your hexagon bar to exact lengths and tight tolerances in-house, courtesy of our central warehousing facility. We also perform processing services throughout our dedicated service centre network.

Stainless Steel Hexagon Bar 316/316L is a hexagonal shaped 316/316L Stainless Steel Alloy bar.

316 Stainless Steel Alloy is a standard molybdenum-bearing grade, the second most commonly sought after grade next to grade 304 amongst the austenitic stainless steels.

The molybdenum gives 316 better overall corrosion resistant properties than Grade 304, particularly higher resistance in chloride environments.

Grade 316L (L= low carbon) ) is the same as 316 except it has an extra-low-carbon analysis, the advantage of which is that it precludes any harmful precipitation in the 800º F to 1500º F range that might result from welding heavier sections. Therefore 316L is extensively used in heavy gauge welded components.

We support our stainless steel stock with a wide range of shapes and sizes to suit your engineering applications.

We hold thirteen different types of shapes to support the grades of material we stock, including bars, sheets and plates.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.